In reply to everyones comments on here, I imagine the whole unit will be fairly heavy probably in the region of 40-50 kilos when fully loaded with trains. I hadn't thought about using a ballscrew to raise and lower the whole unit but they are very accurate. Each lift will be in the region of 50mm +/-5mm distance apart and will have 4 tracks width of storage on each level as per the drawing I loaded earlier, I obviously want to get as many layers as are permissible on the unit for maximum storage space. There used to be a company that made a unit for this very purpose but I think they have gone out of business now, and were extremely expensive hence my attempt to build a custom unit. the link is https://www.nelevation.com

There used to be a company that made a unit for this very purpose but I think they have gone out of business now, and were extremely expensive hence my attempt to build a custom unit. the link is https://www.nelevation.com /p>

It may be worth looking at their mechanical, electronic and technical specifications for ideas.

They seem to be using dc motors with rotary encoder optical feedback to ensure track alignment accurate to within 0.05 mm and PWM control.

Something like the self cleaning beryllium copper contacts could be used to indicate contact at each level? Something like the sliding contacts you will see in the old windscreen wiper motors.

Hi @thephilnewman

there is annother aspect which is quite nasty when you use stepper motors. The spindle will resonate at its base frequency and integer harmonics - like a string on a guitar. The construction will start shaking and rattling very violently - so strong that the stepper will loose steps. Even worse when the lift moves up and down - resonance frequency changes - like pressing on the fingerboard on a guitar.

You could program different speeds for each lift level, which are in between adjacent harmonics. The problem is then - with different load situations - resonance frequency changes as well. To tune all those possibilities to be in the right spot is a nightmare. Ask me why I know this... Therefore I'd strongly recommend to use closed loop dc servos!

Rule of Thumb in hardware/software engineering:

From the estimated time to complete a project you need:

5% for the engineering itself

95% securing everything against any strange idea users can have

and the remaining

150% for finding and fixing bugs that you thought never could happen

Hi @hzulu & @thephilnewman & @robotbuilder,

Apologies, but I was not expecting it to carry 40-50 kg of track+trains, if that is what you are suggesting. This would clearly require a physically robust system. I glanced at the website referenced, which mentioned 1kg/train, 6kg total, which would clearly be a lot simpler specification to work to. Please treat all of my comments as only expecting a 'lightweight' load (a few kg at most) to move, and adjust accordingly if that expectation was ill-founded.

As for vibration, then yes stepper motors have a natural 'cogging' motion which I mentioned before, and that can of course result in resonance problems if the 'cogging' rate corresponds to a mechanical resonance of the system.

Whilst others have much more experience, I note that resonance is one of the main issues with 3D printers using stepping motors and as such is a problem that has been actively addressed. Firstly, by introducing microstepping, so the electrical drive no longer 'jumps' from one rotation angle configuration to the next in a single step, but rather 'migrates' through a series of microsteps, with common controllers supporting up to 256 microsteps for each 'physical' motor step. In terms of small 3d printers, this means the motion of the stepper motors is much 'smoother'. hence, they are nearly inaudible (at least compared to small fans also fitted to 3D printers), whereas before they made a considerable amount of noise. This should generally reduce the amount of energy available to excite any resonances of the system.

The controllers (or the 3d printer's 'system' controller processor) may also accelerate and decelerate the stepping rate to keep the motor within its physical capabilities, allowing for the inertia of the mass is moving, thereby eliminating the electrical stepping drive becoming out of sync with the physical motor position.

In addition, as some overall motions encountered during printing can also excite a mechanical resonance, some printers are beginning to acquire acceleration sensors which sense any 'excessive' vibrations and dynamically alter the rate of motion to avoid the resonance.

For systems used in 'budget' 3D printers, these changes can be added for a few dollars worth of extra electronic hardware per motor, albeit they also need at least one controlling processor and associated software to support the enhanced functionality.

The controller chips used for 'budget' 3D printers directly control the current flow into the stepper motors, and hence the chip specifications limit the size of motor they can drive. Depending on the load, gearing, etc., you may need higher power stepper motors than a small 3D printer would use. However, at least one of the controller chips is designed to drive external MOSFETs, so that higher power solutions are also feasible, albeit at some increase in cost and inconvenience.

Of course, all of the above comes with a level of complexity that might be more than you were originally expecting, but in my experience, in engineering, the full solution can often involve a lot of detailed work to produce what appears to casual onlooker to be a 'simple' solution.

--------

I note the above discussion included comments on using spring contacts to transfer power between the rail sections. As a suggestion, whilst the commercial product solution mentioned is 'tidy', depending upon your metalwork capabilities, it might be easier and more reliable to do this by external wires and/or connections.

-------

Best wishes all, Dave

@davee I based my weight on the following, each locomotive weighs roughly/average 120grams then add eight or nine coaches to that, there not that heavy but assuming 80grams per coach is say 840grams per train, then multiply this by 4 lanes wide which comes out to 3.36KG then multiply that by 9 for the different levels. The rolling stock alone comes in at just over 30KG and then there is the weight of the frame and unit itself. This is what I based my calculations on. Dont get me wrong I'm not loaded with cash but I want the unit to work well so I am prepared to spend what is needed on the right equipment to make it work, if a DC motor with an encoder is a better option then I will go with that, but I will probably need a lot more help with setting something like that up. I have a friend who bought one of the Nelevation units a few years ago when the company was still trading, and I dont think it was cheap, ut one of the constant problems he has with the unit is the the shelves in it bow with the weight, that is why I would rather over engineer it to be on the safe side.

Cheers Phil

Hi @thephilnewman,

I am not a mechanical engineer, and there is definitely a strong mechanical engineering side to constructing a device that can shift 30-50kg of stuff up and down with precision of (say) 1 mm or less.

Initially, I hadn't appreciated you were looking to have 4 trains on each level, etc., and hence imagined a much smaller and simpler system. You are clearly contemplating a very impressive device!!

--------------

A substantial part of my concern will be how much of that 30-50kg weight will be continually trying to rotate the motor. I note the commercial product says it has a counterbalance, but I am not clear how that is applied and whether it can compensate for the weight changes when the trains are in the lift or out on the track (assuming the lift will sometimes be 'full' and other times partially filled or empty).

--------------

Obviously, a considerable amount of gearing will be involved, which will also bring its own issues.

Personally, I think I would start by trying to design the mechanical arrangement, assuming an arbitrary 'motor' is available to drive the appropriate shaft of the arrangement. I would include sensing mechanisms to determine the mechanism position. I might even be tempted to make a crude prototype with representative weights, etc. to simulate the loading, as a testbed for any motor/control system.

I presume the mechanism will need to apply vertical force using at least 3 or 4 vertical supports ... e.g. 3 or 4 theaded rods or belts .. to ensure the lift remains horizontal at all times. Coordinating all of these will be an issue in it own right.

For a specified mechanical arrangement, it should be possible to estimate the actual loads, both static and inertial that the 'motor' will be required to handle.

Then, look to see what forms of motors, gearing and control are available, matching their capabilities to the specifications. Obviously, the needs of the overall control system will be affected by the type of 'motor' you choose.

---------

I am not qualified to judge whether stepper, servo or whatever is the best system, as I do not have the range of experience in such a demanding application. My feeling is the 'cogging' effect of steppers, that can readily excite resonance conditions is probably solvable, but offer no guarantees - I am just discussing it as an alternative to consider.

Intuitively, I would have thought a DC motor would be quite difficult to control with sufficient finesse, although if it has a high gearbox ratio so that many revolutions of the motor equate to small change of lift platform height, perhaps that becomes less of an issue.

Note that a stepper motor, when powered to a specific step position, is actively held in that position by a constant DC current drive... it will only move if the rotational force applied to the rotor exceeds the holding force that applies for that particular motor, when energised at that particular current. Thus if the motor and current are conservatively chosen with respect to the rotational forces it experiences, then it should not move.

I presume that when a servo motor is holding a particular position, the servo control mechanism is continually trying to balance the current through the motor with any turning force applied to the rotor of the motor. In this case, the turning force will be related to weight of trains, etc of the lift platform. If that turning force changes, I presume the rotor will initially start to move and then be corrected by servo mechanism to move it back. Whether this will mean that the lift will appreciably move up and down as a train moves on to or off from the lift platform section, I don't know - I presume it wil be critically dependent upon a lot of issues, including the magnitude of weight transfer, the gearing ratio, the motor characteristics, the servo characteristics and so on. I think it can even set up an oscillation in some (badly adjusted) circumstances, but this pure speculation on my part.

---------------

I wish you all the best with your substantial and impressive project.

Dave

@davee @thephilnewman, I didn't mention counterbalances because I thought it was common knowledge. Most commercial elevators, when they (very rarely) fail, in fact, 'fall' up. It's just a matter of determining your min, max, and average static load and installing a counterbalance for the most common load. I have no idea how that is done in a screw drive. Have you considered a hydraulic lift? You can get tremendous mechanical advantage, and the precise positioning can be controlled by a lift above, stop the motor, open the micro drain port, close the drain port and apply brakes sequence.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

My personal scorecard is now 1 PC hardware fix (circa 1982), 1 open source fix (at age 82), and 2 zero day bugs in a major OS.

@thephilnewman, et al,

I originally didn't recognize the file "Train Lift.ods". The only thing I had to look at it was Excel which I thought was rather odd. I've never seen this file type before. I was thinking that we were moving maybe one car or locomotive on an elevator car up to nine different levels like a human elevator typically does. After finally zooming out Excel, I now see that you are moving all nine levels as one elevator car.

The links below are only representative and shown to get the idea. They are not meant to promote the usage of a particular vendor.

Although I think any of the suggestions can be made to work, I personally would still go with stepper motors.

Threaded Rod - I would still use the cheap finer threaded rod that you can get at Lowes/HomeDepot type places. I'm thinking you'll now need to use four rods (one at each corner) of an elevator car. Six foot lengths and 20 threads/inch will easily get you the fine height accuracy. (1 micro step = 0.000016") I think the 50kg loaded elevator cars is wildly pessimistic unless you're making the whole thing out of steel. 😆 Even so, these rods should take care of it. You can get bronze nuts to rest the elevator cars cars on and with working of the rods they can be made to run smooth. Any issues of strength or thread binding can easily be handled with some string, pulley and counter weight.

"https://www.lowes.com/pd/Hillman-1-4-in-dia-x-6-ft-L-Coarse-Steel-Threaded-Rod/3128761"

Stepper Motors - I'm thinking the cheap ones I posted earlier are not up to the task. I'd go with something like:

"https://www.amazon.com/STEPPERONLINE-Stepper-Bipolar-Connector-compatible/dp/B00PNEQKC0/"

Stepper Motor Drivers - Although there are better drivers, I think you could still go with the A4988 drivers.

"https://www.amazon.com/Stepper-Compatible-Stepstick-Printer-Robotics/dp/B09FQ3G5XQ/"

One of the main reasons I suggest this strategy is you have indicated that the software side is the most challenging part for you. Model railroaders I know are true craftsmen on construction. Even the mild electronics that will be involved in this will be old-hat. Software for feedback loops on plane motors is not something I would want to tackle on synchronizing 4 separate DC motors at the resolution you will need. And then comes accelerating and decelerating into a "floor" and synchronizing. I've not seen anyone on this forum show a video of even a two wheel synchronized bot that can hold a strait line for say... a hundred feel and hit a spot consistently (as in twice in a row). I would very much like to see such a bot and the software required... even with vision.

Yes it can be done, but when the stepper motor equivalent is simply saying something like go to step 256992 to get to floor 5, I don't see the point of being a masochist. 😉 The stepper motor can easily be accelerated/decelerated and maintain step synchronized (0.000016 accurate) without any back feed coding required. All four corners could be calibrated say (256992, 256834, 256723, 256857) to take into account any construction variance. They won't need software to monitor a sensor that they are "near" a floor to start slowing down. They won't need software to monitor a sensor that they are at a floor.

I like the KISS principle. There are millions of 2 and 4 threaded rod elevators working every day that stay perfectly synchronized and are accurate to 3 decimal places in millimeters! They're called 3D printers. Mine has gone through 81 km of filament with no stepper motor mishaps.

VBR,

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq hello, the file I added was done from a piece of software similar to Microsoft excel called Libre Office it is a free download on the internet. I have been doing some more research and found another company that actually makes these things I have downloaded the data sheets and converted them to English through deepl. I will attach them below. I can easily get hold of some good quality threaded rod although the thread will probably be metric as I am in Kent in the UK. Are you suggesting using four separate stepper motors for this? If this is the case would there be any chance of sending me a small sketch showing how these would be mounted and connected to the threaded rods, also would the unit not be inclined to "bind" using four different motors. Like you said KISS, I am all for keeping it as simple as possible especially with my programming knowledge. I have also found another very useful website for getting other parts to build this unit with it is called OpenBuilds part store they seem to specialise in equipment to build your own frame work which is very useful. I will also try to attach a JPEG of my layout so you can see where I propose to install this unit when it is built. I can also take a couple of photos and send them if you think it would help. On the PDF the section that the lift will operate through is shown in Mauve colour, it is going from a lower level to the upper level.

Cheers Phil

Is it necessary that there be 4 trains per lift section, or do you just need to on/offload one train at a time ?

Anything seems possible when you don't know what you're talking about.

I will attach them below. I can easily get hold of some good quality threaded rod although the thread will probably be metric as I am in Kent in the UK.

Threaded rod - I think it was @davee that pointed out courser thread at some point will feed back. IOW, if you push down on the "nut", the rod will turn. My 3D printer has about 15 threads/inch (6 threads/cm) and it exhibits this tendency somewhat. Bolts at 9 threads/cm do not. You can pretty much stand on the nut (somehow 😆) and it wouldn't cause the rod to turn. I would try to stay above that.

Are you suggesting using four separate stepper motors for this?

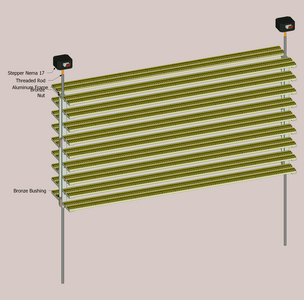

4 Motors - After my last post, I recall that N-scale is only about 10mm wide. Am I correct, that your elevators are only 1 track width and about a meter of track??? If so, I'm sure your building skill will let you reduce it down to one stepper at each end and the slight cantilever of several centimeters shouldn't be an issue with your structural/deflection of your elevator car.

Binding - (4 or 2 motors) This won't be an issue once you get everything all setup. Many 3D printers with 2 z-axis motors driving screws (your exact situation) use the lowest of Arduino running at 16MHz and they can only step one motor at a time. They step one motor, then the other. But because of the time space between those (micro seconds) and the small distance they move 0.005mm, binding isn't an issue. Take a look at my robot that has to synchronize two steppers where it had to even account for the micro differences of two wheel diameters (printed from the same 3D printer and the same wheel model) - https://forum.dronebotworkshop.com/postid/33699/ .

If this is the case would there be any chance of sending me a small sketch showing how these would be mounted and connected to the threaded rods

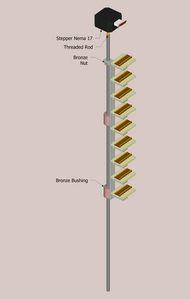

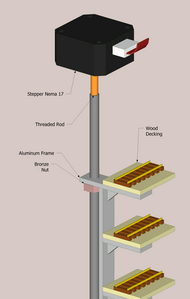

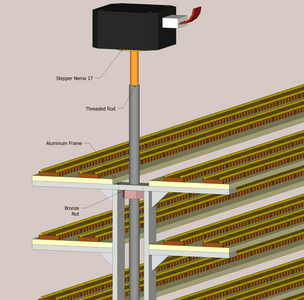

Sketch - I'm assuming your talking about structural sketch, not Arduino Sketch. Also, I don't know what skills you have. I'm guessing you can do soldering of bronze/aluminum??? If so, something like this. Without reading through the whole thread again, what weight of trains and track would be on all the levels at one time? (worst case). Growing up, I had HO, but I can imagine you're talking anywhere near 50kg. If you are using wood, I'd say it'd have to be beefed up. My mind's eye says something along these lines should do.

Showing just one end. Mirror other end.

Detail

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Software - You mentioned something about integration into some other system. What does that entail?

Also, I prefer to use web interface design principles. IOW, you'd control it from any browser... phone, laptop, tablet, PC. You'd be able to see where each elevator is and be able to calibrate the stepper motors from a virtual interface. As it is all virtual, you won't have any expenses.

If you are more interested in a physical interface, you'd need to get some other's help here on the forum on integrating buttons, dials to control and calibrate it and display's if you want to monitor it. I don't have any experience using those.

If a virtual UI is of interest, and if you want my help, you'd have to use my library to control it and have to run it on an ESP-8266. I would recommend a NodeMCU for the microprocessor.

"https://www.amazon.com/HiLetgo-Internet-Development-Wireless-Micropython/dp/B081CSJV2V/"

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq I am very surprised you are unaware of the Open Document Standard. It's not often I know something that @inq doesn't, I will definitely frame that one LOL! 😀

BTW, my hydraulic solution automatically stays in sync thanks to the laws of Pascal.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

My personal scorecard is now 1 PC hardware fix (circa 1982), 1 open source fix (at age 82), and 2 zero day bugs in a major OS.

@inq I am very surprised you are unaware of the Open Document Standard. It's not often I know something that @inq doesn't, I will definitely frame that one LOL! 😀

BTW, my hydraulic solution automatically stays in sync thanks to the laws of Pascal.

🤣 Professionally, I was a Microsoft disciple... Windows, Microsoft Excel, Word, Visual Studio. Never strayed to far.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

I was confused by @will last post. So I found I hadn't zoomed out enough with your spreadsheet drawing. Now I see they're symmetric. So... from the front view... is there three independent elevator cars or is it one long (3 bay) elevator car?

Now I can see it might be 50 kg!

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide