At my age, I'm entitled to make mistakes. @zander keeps count, but I think I've had my quota this month. But I made a real fundamental mistake...

My main goal with Inqster was to study Artificial Intelligence (AI) using Artificial Neural Network (ANN) and Genetic Algorithms (GA). The main aspect about using either method, is the bot learns how to run the bot. I don't have to explicitly write code to use sensors to say... something is in the way, go around it. Like a child, the bot needs to run into it half-a-million times, say ouch and finally veer around it.

The error of my ways that I was re-reminded of, I found in @thrandell study using GA with his Swarm Bots. I'll be basing the initial work on the same paper @thrandell used - Automatic Creation of an Autonomous Agent (ACAA). The one difference, I'll start out using ANN techniques versus GA as it just makes more sense to my brain. The one key aspect I forgot... it takes time for it to learn. Inqster is big and uses a lot of juice, but has to run on batteries as it's meant to play outside like all kids should be forced to do (IMO). It might run for two hours... his study took over 30 hours.

Thus... InqEgg is hatched.

I'm backing up (relative to the goals of Inqster) to making a smaller (indoor only) bot using a power umbilical chord so it can run non-stop as long as it's tiny brain needs. It won't have all the capabilities, but hopefully some or all of its learned brain might get transplanted into Inqster.

Specs

- WeMos ESP8266 - Although less powerful than the Inqster ESP32-S3, I don't have to write a new web server library for it. It's already in the can.

- Nema-17, 23mm stepper motors. Far smaller and less capable than Inqster's 49mm motors, they should still drive InqEgg to unheard of accelerations and speeds, not having to cart batteries around with it.

- DRV8825 stepper drivers - This is a mid-range driver. Inqster will use the TMC2209 drivers that will allow run-time configuration and monitoring of the current being used by the motors. Very sophisticated technology, but needs a serial port to use and thus needing the ESP32-S3 and can't be used on the ESP8266. But, it handles more power than the A4988 drivers used on Inqling Jr.

- It will have the 10DoF - Gyro/Accelerometer/Magnetometer/Barometer on board that will eventually be entered into The Brain but I don't expect to use it in the initial obstacle avoidance learning curve.

- VL53L5CX - 8x8 resolution with 45° FOV, Range 4m. I hope to use this as the primary vision method, but at first, I'll only use the one row that aims horizontally strait ahead. Although ACAA used two sensors facing re-ward, I'm going to try avoid adding those. I don't have eyes in the back of my head is the simplistic rational.

- Wheels, tires, chassis will all be 3D printed because its fun and far cheaper.

Let the games begin...

VBR,

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

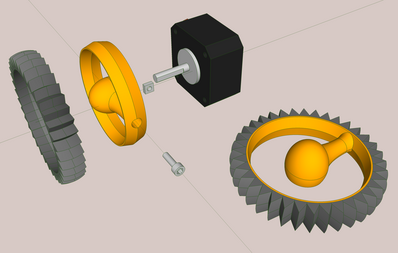

CAD work for the wheels is done. I've noticed that the steppers get pretty hot and the wheels on Inqling Jr. started ejecting at high speed due to softening of the ABS plastic. Oops! Forget about PLA. To try to combat that, the chassis will be open to free air and hopefully the steppers get a little more cooling action. Also, I plan to print the wheel in Polycarbonate / Carbon Fiber. The PC has a little higher melt temperature than ABS and the carbon fiber is a better conductor. In theory, it might distribute the heat throughout the wheel versus softening it right next to the shaft.

It incorporates a trapped square M3 nut and uses a single M3-10 bolt down the single spoke to fasten to the shaft's keyway. The tire is the softer TPU plastic. Even though it is flexible, it is still shiny and doesn't really get that good of traction on a hard floor. I might have to use rubber bands for that case. The tread should be killer on carpet however.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Hi @inq,

Hopefully you will get an informed answer. In case not:

I just googled AliExpress with 'rotary connector' and various slip ring things appeared ... never used or seen one, so I can't advise further.

https://www.aliexpress.com/w/wholesale-rotary-connector.html

If they are in AliExpress, they may well be in the more local bazaars, albeit probably at inflated prices,

Best wishes, Dave

I moved this over here. @thrandell prefers me to not distract from his thread too much. So I try to keep my posts there as pertinent to his project as I can and as concise as I can (and often fail).

But... $29 on AliExpress would totally blow the budget on this thing. So far, all this bot's stuff is off previous bots and will move on to newer bots, except the new DRV8825. I'm out about a $1 worth of plastic so far. Even if I consider the prices of what's in here...

- (2) $6 Steppers (transplant from Inqling Jr (T))

- (2) $3 DRV8825 - New

- (1) $3 EPS8266 - T

- (2) $0.5 Capacitor - T

- (1) $5 10DoF sensor - T

- (1) $1 Buck regulator - T

- (1) $25 8x8 ToF - T

Total: $51 + couple $ in plastic.

Maybe I can find a DIY / 3D printed idea??? Maybe some kind of swipe brushes thing. Maybe, I just let it wind up. I'm not sure how many turns might occur over a bunch of hours.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq Excuse me butting in, but don't the motors have slip rings or equivalent internally, so you don't need to do anything?

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi @inq,

Another goofy idea .... which requires another motor ... but I'm guessing you have a few spare steppers in the junk box.

Imagine a kind of rotating radar dish mount at the power station point, only instead of a dish have a pointer arm, which aims the wire towards the bot (instead of radar pulses).

This will still require some kind of slip rings, but being motorised, they could be relatively high friction, so hopefully easier to fashion out things like a piece of pipe or whatever, whereas a light-weight wire will only have significant 'pulling power' when it is tight, which will not please the bot.

Of course, this means the dish has to know the approximate angle to point towards the bot, but errors of up to say 45 degrees are probably not important, and I presume reasonably accurate 'Where am I?' data will be needed, if only for monitoring and training.

Probably totally over the top ... and the obvious answer is looking me in the face.

Best wishes, Dave

Postscript ... Of course, I have only been looking at this from the point of a bot travelling around a power island.

The bot might decide to be a ballerina, and start a pirouette about its location. The same solution is valid, but I can understand if you want to avoid such a contraption to a bot.

@inq Excuse me butting in, but don't the motors have slip rings or equivalent internally, so you don't need to do anything?

Totally my fault - I asked the question in another thread, but transferred the reply here. InqEgg is going to be the one tethered to the ceiling with the wire we've been discussing for power transmission to power it. For Dave's response, I asked how to handle the bot spinning around and winding up the umbilical. I'm looking for some design that might be reliable enough so I can print it. The cheap, off-the-shelf were $30 on AliExpress and I hope to fire this thing up this weekend or next week.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq Whatever wire you decide on, make sure it is NOT solid; you want very fine individual wires woven into a shielded 22AWG wire.

Also, you will need to provide really good strain relief. Flexing where the wire enters the terminal connection will eventually break off the wire so make sure it can't move.

I just realized my previous comment was wrong as it did not address the actual issue, so some slip-ring arrangement will be required if the bot has totally free movement.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi Roy @zander,

Actually stepper motors, and other types of motors including synchronous and BLDC - brushless DC, do not have any brushes or slip rings.

Common brushed motors, which until recently were the norm for most domestic motors (drills, mixers, lawn mowers, etc) have commutators and brushes, but not slip rings.

To the best of my knowledge, slip rings are now only commonly found in things like alternators, and even there they are used to pass a DC current through the rotor to create a magnetic field. It is more efficient to use permanent magnets for this job, but using an "exciter" component eases some of the control concerns.

However, all of this bypasses the main point ... the wire needs to send DC power to a buck converter and stepper motor controller ... it does not directly go to a motor.

Best wishes, Dave

@davee Sorry, I made 2 errors. First, I didn't realize it was the bot turning that was the problem, and secondly, I was using 'street' language re slip rings etc.

Just ignore that post, it was really not my best.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

The cheap, off-the-shelf were $30 on AliExpress and I hope to fire this thing up this weekend or next week.

How about $11 for a 6-wire version from Amazon,com ?

"https://www.amazon.com/Comidox-CIRCUITSx2A-Capsule-Electrical-Equipment/dp/B07H2SRMXP/ref=sr_1_6?crid=XGOUBTTWTKLB&keywords=slip+ring&qid=1693585351&sprefix=slip+ring%2Caps%2C164&sr=8-6"

Anything seems possible when you don't know what you're talking about.

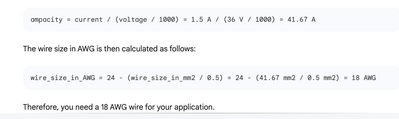

@davee @inq I found this formula. I think we now have several approaches and they all converge on a range of 14 to 22 so 18 seems like a reasonable mid point although lighter may be needed for freedom of movement so 22 comes into play there.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

The cheap, off-the-shelf were $30 on AliExpress and I hope to fire this thing up this weekend or next week.

How about $11 for a 6-wire version from Amazon,com ?

"https://www.amazon.com/Comidox-CIRCUITSx2A-Capsule-Electrical-Equipment/dp/B07H2SRMXP/ref=sr_1_6?crid=XGOUBTTWTKLB&keywords=slip+ring&qid=1693585351&sprefix=slip+ring%2Caps%2C164&sr=8-6"

BOOM! It said I could get it tomorrow if I ordered in the next 5 minutes. It sounds like the thing I need. On the way! Thanks. So that's what it's called.

Edit - Says it's even made for robot monitoring. Didn't know there was so much demand! 😆

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

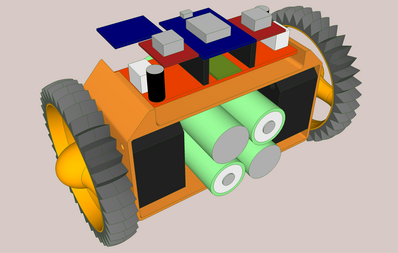

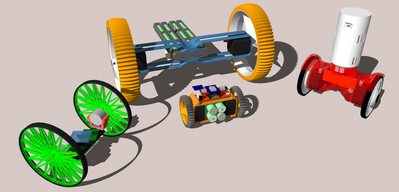

Wheels, tires and chassis are designed and just now coming off the printer. The chassis is in ABS so I can attach (fuse) things to it readily. It only holds the steppers, main wheels, the motherboard from Inqling Jr and has provision for a quad size 18650 battery pack. After learning, I want it to drive severed from the umbilical. Probably train it with the batteries so that the inertias will be about the same with and without the umbilical. I have not designed the fore/aft wheel/rollers. It is not going to be a balancing robot. I have some nylon rollerball thingies due today that I think I can use for those. We'll see!

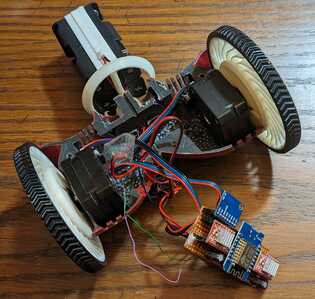

Here is the family picture.

Edit: STL files for wheels, tires and chassis.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Hi Ron @zander,

I am sorry, but please understand that wire size depends upon lots of things, including the environment, how it is wound, what the insulation, how many cores and so on. This is why when @Inq Dennis looked at a web site he was surprised at the different current ratings that could be assigned to same core size.

Many peple are used to wiring in particular environments, maybe like in domestic and factory buildings, where it is reasonable to make a set of 'rules' that define how wiring is fitted etc., and then include a good safety margin, it is possible to have a set of 'simple' tables that says a particular cable can carry a particular current.

But if you change the environment, and/or the priorities, then these rules and tables are no longer appropriate.

Equally, unless you know the conditions that a the formula is designed for, it may be completely inappropriate.

------------

In Dennis @Inq's case he has asked for minimum weight, two cores suspended in air, margins can be at minimum, because in the unlikely event of fault he can intervene, high quality current limiting is provided, insulation may be able to cope with high temperature and power loss/voltage drop is of no consequence.

It is difficult to think of an environment and set of priorities that differs more from 'common power wiring' cases without going into space in a rocket.

-----

And unfortunately, I may be having a bad day, but at first sight, the first 'ampacity' equation in the screen shot you quote, appears to me to be complete nonsense. There is no contextual information, so I don't know its providence, and I may be missing the point.

I am familiar with the term "Ampacity", although it is not normally used this side of the Atlantic, and this definition (from https://www.cerrowire.com/products/resources/tables-calculators/ampacity-charts/) matches my understanding.

Ampacity is the maximum current that a conductor can carry continuously under the conditions of use without exceeding its temperature rating. Current is measured in amperes or “amps.”

The screenshot says Ampacity = 41.67 A ... ,

but excluding the feed cable from the company, I do not have a wire in my house with a rating that high!

Furthermore, it doesn't appear to balance in terms of units, and it includes voltage, which has no bearing on the current carrying capability.

So what it is trying to explain, I have no idea.

-------

Sorry Ron, perhaps its me being thick yet again, and i offer apologies if I am, but I don't think you are onto a winner.

Best wishes and take care, Dave