TM-comp

Sorry for my bad English not my native tongue!

Hello I started designing a CNC machine router!

Still figuring out the electronic equipment!

- 4x Nema 23 3v?

- Stepper drivers?

- Arduino or?

- Power supply?

- End stops?

- How to connect?

- Anything else?

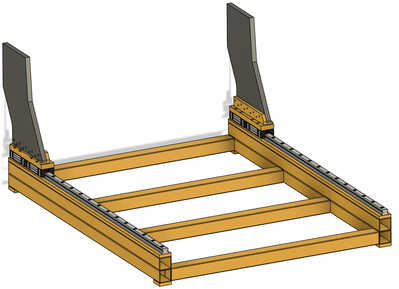

Design so far pic of Y-Axis

Looks like a great start. Here are some replies to your list, but I still suggest you go over to the other forum and check with people that have actual first-hand information about making a CNC machine.

Stepper, Stepper Drivers, Power Supply - I've only used the Nema-17, so again, contact experts on the other forum, but I can easily tell you none of them will work with 3V input. My Nema-17 run anywhere from 12V to 45V. Anything less than 12V and they'll stall and lose steps. Here is how to think to pick your parts. These steps should be just as valid for '23 as '17s.

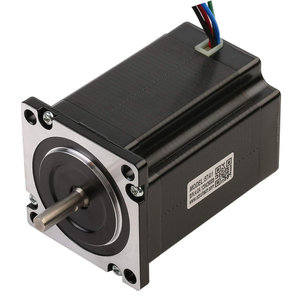

- Pick your stepper motor based on the torque you require to drive you CNC machine at through your chosen materials. If you know how to calculate this required torque or even estimate it, I'd at least double the number or triple it for when thing are different than your estimate. 10x wouldn't hurt either. I can assure you Nema-23 through a screw drive can push some very high loads.

- Find it's maximum current capability of the stepper motor. In example, this one can handle up to 2.8 A...

You'll note that almost no stepper motors specify their voltage. That is because, that is the responsibility of the stepper-motor-driver.

- The stepper-motor-driver you pick will have a way of setting the maximum current it will deliver. Once set, it will not exceed this value no matter what the load condition is or how fast you are asking it to move. You will need to find a driver that is capable of delivering the current you want to use.

- In example my robot that I'm currently working on uses small Nema-17 motors that are capable of up to 1.8A, I have stepper-drivers that can go up to 2.1A. I can adjust them to the 1.8A setting, but I have chosen to only allow them to go 0.5A. In my case, I don't need that much torque. In your case, you probably should count on using every bit... Who knows, you might end up wanting to mill aluminum! 😉

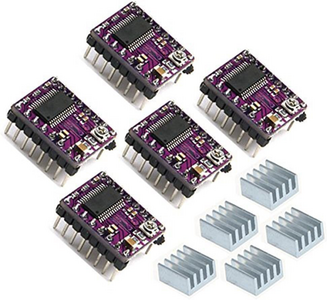

- This is unfortunate as the cheap and readily available drivers used in 3D printers only seem to go up to about ~2A. These are less than $2US. https://amz.run/7L1a

- These would function just fine with the bigger Nema-23, but they could not drive them to their full potential. Although not linear, a rough estimate is that you would only get 2.1A/2.8A*1.2N-m = 0.9N-m of torque using these tiny/cheap drivers.

- Unfortunately, you'll likely need to go to something a lot bigger and more expensive like

Bill has a YT on these bigger ones that might get you started.

- It will be the stepper-motor-driver that tells you what voltage you need. This big one is good from 20V to 50VDC. Any voltage in that range will work, but the higher it is the better. I would shoot for one of the 48V ones like

that can handle the sum of all 4 stepper motors maximum current and allow some extra for the electronics.

Arduino - I would say a definite NO! As I mentioned in your other thread, Things have moved on. Something like these https://amz.run/7L1k are what you need to look for. Unfortunately, these 3D printers motherboards come with drivers on them, but they're the small ones only good up to about 2A. There might be some that can connect to the external, large drivers, but I wouldn't know about those. All these boards will run dedicated software like Marlin or Klipper. There might be a software code base dedicated for CNC as far as I know. But unless, you want to spend years writing code from scratch, you won't want to start with an Arduino.

VBR,

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Great information there thanks!

Am i posting in the wrong forum?

What other forum do you mean?

TM-comp

Sorry for my bad English not my native tongue!

What other forum do you mean?

Please refer to your intro thread. I replied there with details also.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

TM-comp

Sorry for my bad English not my native tongue!

@tm-comp, meaning Introduction thread... your first one.

https://forum.dronebotworkshop.com/introductions/hello-my-name-is-thomas/#post-43968

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@tm-comp A forum specializing in CNC machines.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi @tm-comp,

@inq has given you some great advice. I would just like to add a couple of comments, which might be helpful..

3V stepper motor voltage.

It is common for manufacturers of stepper motor manufacturers to quote a voltage (and consequent current) per winding to hold the rotor at a the present step position.

e.g. https://components101.com/motors/nema-23-stepper-motor-datasheet-specs

includes: Each phase draws 2.8 A at 3.2 V, allowing for a holding torque of 19 kg-cm.

In principle, 3.2V could be used to drive the motor, but the inductance of the coil opposes the current flow when each new step is commanded. This means that it would only be possible to step very slowly, as it could take a significant time for each step to occur so that attempts to step more quickly result in missing steps.

Hence, the controller/driver devices apply a much higher voltage, but in a controlled pulsed form, that aims to achieve the specified current whilst stepping, as well as when holding it to the specified value when stationary at a commanded step position.

------------

A @inq says, many of the common 3D printer motherboards are limited to a lower current and voltage rating than Nema 23 motors need for maximum performance, whilst higher power units like the DM556T, which can drive one motor per unit, are available.

I have no personal experience, but note a possible intermediate approach. Available driver boards of a similar form to the small PCB modules illustrated, are advertised which are typically based on TMCxxxx chips, and claim higher voltage and current capability than the low cost boards shown. Not surpringly, they are usually more expensive, and care will needed to ensure a suitable motherboard is also chosen to mount them on. I do not know whether, they will be a better value solution, but they might be worth investigating. As Inq has suggested, forums specialising in CNC may be able to provide some 'hands-on' advice.

-----------

Note Marlin, and presumably other comparable software 'packages', are complex libraries of software, typically written in C++, that I imagine could be daunting for anyone not familiar handling programme suites of the chosen language and size.

In certain cases, such as the more popular commercial 3D printers, prepared packages are available, plus YouTubes, etc., making the process of compiling and installling reasonably accessible. However, I don't know what is available for the 'home-brew' CNC machine you are contemplating.

Before committing to purchase the components, you may wish to look into this aspect, to see if a realistic path is available, as it could be very frustrating to get stuck halfway through. Of course, if you have appropriate software experience, this may not be concern and I apologise for raising the issue.

---------

Best wishes, Dave