Hello I started designing a CNC machine but I am confused over all linear rails and ball screw vendors that's out there (Amazon, Ali, Banggood, Temu.....) (Linear rails 20mm x 1000mm , 750mm and 450mm times two, ball screw 1000mm, 750mm and 450mm) ware to find good quality and to a decent price.

The same for electronic equipment!

- 4x Nema 23 3v?

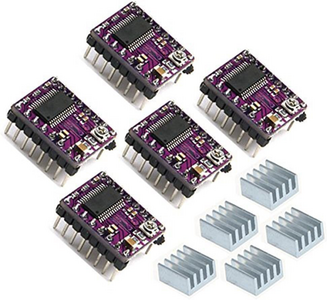

- Stepper drivers?

- Arduino or?

- Power supply?

- End stops?

- How to connect?

- Anything else?

Need to understand what to buy and from whom.

TM-comp

Sorry for my bad English not my native tongue!

Posting a pic of Y-Axis!

First draft using Linear rails from a project @ work (weary expensive Rails)

TM-comp

Sorry for my bad English not my native tongue!

. They are available in different diameters and lengths on ebay, amazon, etc.

Tons of great information. Only one aspect I think I'd like to clarify...

The downside of micro-stepping is reduced torque since full torque is achieved only for maximum rated current, and some tuning may be required to achieve best performance

Is this something with the larger (non 3D printer) drivers for the bigger Nema-23 steppers? The reason I ask...

versus

Full steps mean only one set of coils are active. Whereas, any intermediate step in micros stepping both sets of coils are active and the tiny 3D printer drivers are usually rated for maximum current per coil, not per driver. IOW, at the half step both coils can be delivering 100% and thus be exerting 141% of the force of a single coil at a full step. @davee did a long dissertation on this and I've seen it in practice. Although I did believe what @davee said (charts and tables from manufacturers are hard to argue with), I did want to see it in action. I could set my robot to use either full steps or 1/32 micro-stepping. Having it go to a given speed, it would need to accelerate (torque being applied). As I asked it to higher speeds in less time requiring more torque, the micro-stepping mode would clearly reach higher accelerations. The full-step mode would at lower rates finally start chattering and not move the bot at all. Anyway, wondered if the big box drivers work differently???

Another question - You obviously have a lot of experience doing these linear movement/track type projects and know when you can economize on certain pieces and when you can't. I have this project that has been back-burnered for years. One of the track dimensions would be 50'. I don't need all that much accuracy (+/- 0.1" would be fine) or extreme forces (< 100 lbs). Have you ever tried using the 10' length hanging ceiling threaded rod? Using bronze nuts as the mating follower it seems to run fairly smoothly and there isn't any play that I can feel.

Thanks,

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Hi @inq,

A couple of side comments, though sadly not answers to your main questions. The second comment is largely based on some notes I have seen in other forum(s), particularly contributions by Mariss in the forum at https://www.cnczone.com/forums/stepper-motors-drives/13678-effect-microstepping-torque.html

Please note, these comments are purely my interpretation of what I have read, and are not based on any personal research, knowledge or experience. Whilst I apologise for any additional errors I have introduced, I am neither supporting or denying any of the suggestions obtained from the forums.

- The highest total current in the microstepping occurs when both coils are at 70.7%, which results in the total that you stated of 141(.4) %. The drive current to an individual coil is only 100% at the the full step positions, when the current to the other coil is zero.

- I haven't checked, but I would imagine the low cost 'boxed' driver controller units will aim for the same microstepping rules as the small PCB based modules, although there are a number of different integrated circuits available to construct the small PC modules, some of which offer more sophisticated algorithms, to allow for inertia, etc. than others. Presumably, there will also be performance variations in the different boxed units as well.

- The torque versus stepping options position appears to be quite complex, because there are a number of effects interacting.

- When the motor is stationary, then the motor is not generating any back emf (voltage), the current can only be reduced by inductance immediately following the last step or micro-step and hence after a few moments, the current will reach the specified value, and there are no mechanical resonances, etc. arising from the motion, so that it is purely a 'holding torque' scenario.

- However, when the motor is being microstepped or stepped, with the motor moving, the consequences of different effects interact to produce a more complex picture. Part of the picture appears to include the suggestion that some more sophisticated controller/drivers may perform more consistently over a wide range of speeds because they include more comprehensive compensation mechanisms, but at the 'simpler' end, I note the following suggestions:

- At stationary and low speeds, the driver is able to control the current, so that the motor is being current controlled, because the voltage supply to the driver is high enough for the current regulator to overcome the motor back emf, and (presumably much of) the inductive current limiting. However, beyond a certain speed, the supply voltage becomes the limiting factor, as the regulator is at '100%' of its range, causing the motor to be voltage driven. Obviously, the higher applied voltage, the larger the range of available adjustment of current control.

- At low speeds, the microstepping provides not only a much smoother motion, but also a higher effective dynamic torque than full stepping. Beyond a certain speed, which the forum discussion suggests is about 3-4 rpm, full stepping becomes more effective as it maintains a slightly higher torque waveform.

- At higher speed, a further problem of mid-band resonance occurs. It is claimed the the more sophisticated controller/drivers can mitigate this effect. Of course, not all applications may require the motor to operate this quickly.

- The more sophisticated driver/controllers may make use of additional sensors fitted to (or close to) the motor to detect certain unwanted behaviour, so that the controller can modify the drive performance to avoid the conditions that provoke the problem.

I hope this additional discussion is of some benefit. Obviously, it is little more than speculation on my part, so please check out any options independently before committing to expenditure of money and effort.

Best wishes, Dave