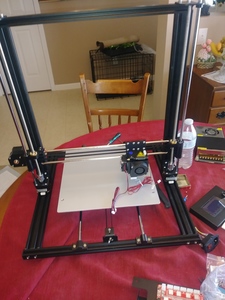

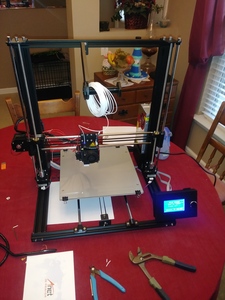

Hold the presses! I think you may have the X-Axis mechanism mounted wrong.

i think you may be right it looks like the whole top section i put on back wards i knew for some reason i wasnt 100% happy about it when i stopped last night thanks for callin that out ? ? ?

I hope we can get our printers working without having to resort to the Facebook site Anet wants us to use! I was just over there and it appears to be a nightmare to try to wrestle answers out of anyone with any expertise.

And since I don't really have any myself, I won't know if someone is giving me expert advise, or just a line of bull. I did not find one instance where responses were from Anet personnel. Just from individuals with an opinion, and you know what the say about opinions!

SteveG

i was a little put off last night when i looked at their website and they had a bunch of people asking question and they all got referred to the face book page

Have you guys seen this video?

DroneBot Workshop Robotics Engineer

James

Have you guys seen this video?

yeah codecage linked it last night i think where i got my self in trouble was trying to do it from th pdf files and it just has no info

hey guys i got it all set up but when i try to load up the filament you can see the gear turn for a sec then stops and jerks a little bit and make a jerking sound just wounder if anyone has any idea's i've tried to change the filament size went up to 2.20 and it was still doing the same thank you in advance

UPDATE i took the extruder off and manually fed the filament in, preheated it and then fed some in either im not strong enough to feed it in while pushing down on the lever or my tip is clogged but either way im work on it again tomorrow

its a pain in the butt but ive learned so much 🙂

getting it lined up to start the feed is a pain ive tried cutting the filament at an angle and also shaving it off in to a pencil tip getting it adjusted just right should be fun

The filament they provide is PLA ?

When you say you "preheated", to what temperature did you preheat ?

This may sound silly, but, remember that the filament starts out at 1.75MM, and is being jammed thru a .4MM hole, which means that something drastic has to happen to either the filament, or the hole. Ideally, you want the drastic-ness to happen to the filament, like, getting it hot enough to get it melty enough to squeeze it thru the hole. A good temperature for PLA is no less than 165C. Preferably closer to 180C

If your preheatedness didn't approach at least 165C, no amount of force is gonna convince the filament to crawl thru that hole

If your preheatedness didn't approach at least 165C, no amount of force is gonna convince the filament to crawl thru that hole

yeah its PLA 1.75 and i preheated it to 220 not sure if it C or F but im thinking C it said it was still at 105 or so and burnt my thumb thats what it was set for and their book (manual) told me to. but my back was giving out so i didnt have to much strength left

Ok. Depending on the manufacturer, 220C could be high by quite a bit. It was probably C cuz I doubt 105F would burn your thumb

Could be a few things going on here. 105 isn't hot enough to melt the filament enough to push it thru the nozzle, on the other hand, if the thermistor isn't reading properly, it's possible that the filament burned, in which case the nozzle could potentially get clogged

Or, the thermistor IS reading properly, and you didn't wait for it to get to 185C

It's brand new. Don't start with 220C. If you can't load the filament at 185, try 190. But, start low, then slowly work your way up. There also might be PTFE tubing inside the "throat" (metal tube between the nozzle and extruder gear), and you don't want that to melt, or it WILL get clogged

Do you have any way of reading the actual temp to see if the thermistor is accurate ?

Do you have any way of reading the actual temp to see if the thermistor is accurate ?

best i could do right now would be a meat thermometer and thats not very good but i should be able to tell if its C or F

cuz I doubt 105F would burn your thumb

yeah i lived in southern oregon for over 35 years and all summer every summer it was over 105F

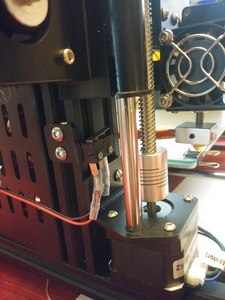

There also might be PTFE tubing inside the "throat" (metal tube between the nozzle and extruder gear), and you don't want that to melt, or it WILL get clogged

i really hope there wasnt one i didnt see any when i took it off but if it melted i probably wont

tomorrow after i wake up ill look in to all that hopefully my back will give me atleast an hour or 2 before it starts giving me problems

also thanks again for all the advise and help, i love this community

I am getting that ratcheting sound out of mine as well. Haven't gotten back to working on it yet as too many things are needing my attention at the moment. And I think my pre-heat temp was 185 (must be C not F).

Did your hot bed line up under your extruder when you did an Auto Home? Mine shows something like -25 for the X-Axis and zero for the Y-Axis and Z-Axis. Got to get that resolved before being able to melt any PLA really matters.

SteveG

I am getting that ratcheting sound out of mine as well.

thats because the PLA filament isnt line up to the extruder the hole it almost the same size as the the filament so i fixed that by taking the extruder out and manually feeding it and carefully putting it back (careful because the filament it brittle and i had mine break off twice)

also you can take a pencil sharpener to the filament to help "thread the needle"

Did your hot bed line up under your extruder when you did an Auto Home? Mine shows something like -25

yeah mine was off but i keep adjusting the x axis switch the video says 7 cm but mine is more like 9 cm (from the top of the pin on the switch)

also make sure you tighten the bed down all the way with the 4 thumb screws so you raise it up for the fine tuning

it did take quite a few times before i got the x axis set

mine dose go all the way to the left when it auto homes to check the x axis but i think thats a safety feature so it wont bust through the glass