Hi @inq,

Part Deux - Supplement 1...

Yes, I am definitely eccentric .. but hopefully I sometimes manage something useful.

I admit this is all based on my thoughts .... I have never done any of this with 'real hardware', albeit that is on the to do list ... so there is a possibility I am making an 'obvious' mistake, but hopefully it is accurate.

-----------------

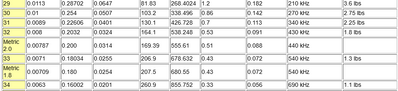

Looking at the Pololu page, it says maximum of 1.5A per coil, to avoid overheating the DRV chip ... I know it says you can add a heatsink, but looking at the tiny piece of extruded aluminium that came with my TMC board, I didn't think something like that was going to significantly increase the current capability, so I stuck with 1.5A as a realistic maximum. Obviously you can pick a lower current if it has enough torque for your task, but assuming Pololu know what they are talking about, I wouldn't recommend significantly exceeding 1.5A.

--------

The weird thing about micro-stepping, is that the total current (for the pair of coils) is more than for a full step position, BUT the total power input is the same. This is counter intuitive, but it is because power is product of both voltage and current. I can give you even more chapter and verse, but I'm not sure that is what you are looking for!

Also, this applies not only to the motor coils, but also to DRV chip.

(I should admit, I'm only just getting my head around this today, as I have never needed to consider it before, hence it is taking bit longer.)

--------

A further point that might be confusing you.

With a normal brushed motor, it takes more power, and hence gets hotter, when it is working harder. If you have used a rotary electric drill to make holes in hard materials like concrete, you will know what I mean.

Unless the designer pulls some special tricks*, with a stepper motor, it takes the most power when it is stationary.

Every time it is stepped, momentarily the current, and hence the power input falls to zero, and then gradually increases up to the full value. Furthermore, the motion of the rotor will generate a momentary voltage which will reduce the current flow.

(*e.g. I think I read Marlin for 3D printers has an option to deliberately reduce the current if a motor is stationary for a period of time, but this requires software current control, etc. to achieve. )

So, from a power supply/transmission viewpoint, the maximum load is when the bot is powered up, but not moving.

I should add, stepper motors have several different mechanisms, including resonance and so on, especially when operating at higher speeds, and my analysis/assertions maybe naive, but hopefully good enough to get started.

--------------

I agree with your numbers for the buck converter and ESP8266. I.e. they will probably manage on about 1 Watt total ... I allocated 2 Watts in the budget to give some margin, and even then it is less than 10% of the total budget.

-----------

Perhaps it isn't obvious, but the ending to Part Deux was about calculating the current in your cable. The current levels in the motors, etc. are essntially irrelevant ... to be more precise they are absorbed into the power budget, which is 26.75 watts.

Based on your previous note, I assumed you were going to use your power supply at its maximum voltage of 32 Volts. As you say, this should be fine for the motor and the DRV chip, and hopefully it will be easy to source a buck converter that converts over 32 V to 3.3 V.

------

Ignoring (for now), any voltage drop across the transmission wire, the 26.75 Watts at 32 Volts, correponds to

26.75 / 32 = 0.84 Amps, which I rounded up to 1A.

That was as far as Part Deux went.

------

You will be aware that switch mode power supplies tend to have high transient currents ... and a stepper motor controlled by a DRV chip is essentially a switch mode power supply, so I would expect to put some kind of filtering on the power input to the bot. I am hoping this will be a simple affair with just 2-3 capacitors, but the 'jury is still considering its verdict' on that one.

--------

I hope this makes things a little clearer, though I appreciate that being theoretical, it is far from the land of magic smoke and reality.

By all means, consider setting up a lab experiment to see if I am on or off the rails. And ask any more questions, etc.

Best wishes, Dave

Hi @Inq,

Part Trois ... the wire discussion.

Parts 1 and 2, determined the requirement of a twin core cable 3m/10' long, carrying 1 Amp.

If you try Googling 1 A capacity, you may find that many cable charts start at about 1.0 sq mm (or equivalent) and have ratings of over 10 A ... not very informative!

https://www.engineeringtoolbox.com/wire-gauges-d_419.html appears to be a little more helpful.

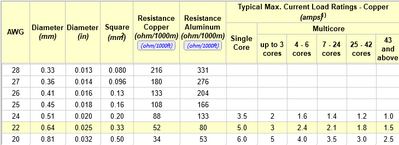

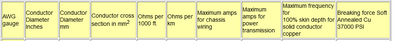

This is a snip from the table:

The smallest wire size it has values for is AWG 24, with a core size of 0.51 mm/0.02" diameter, 0.2 sq mm area, and rating of 2 Amps when in two or three core cable form.

The AWG to current capacity roughly halves for each increase in AWG, so at rough guess, AWG 26 might be able to handle 1A.

---------

It also worth checking the voltage drop, to make sure it is acceptable (albeit, by design, this is very tolerant case, so I will be surprised if it is a problem)

Resistance of AWG 26 is 133 Ohms per 1000 metres.

---------------

Length of required cable is 3m/10' .... but the voltage drop is the sum of the wire in both the forward and return directions, so the effective wire length is 2 * 3 = 6m

This implies a resistance of 133 * 6 / 1000 = 798 / 1000 = 0.8 Ohms

Voltage drop across 0.8 Ohms is given by V = IR, where I is the current, and determined to be 1 Amp

Therefore, V = 1 (A) * 0.8 (Ohm) = 0.8 V

Hence, if the load is 1 A, and the power supply is outputting 32 V, then the voltage at the bot end is predicted to be (32 - 0.8 ) = 31.2 V

This implies a voltage loss of 2.5%.

--------------

A voltage loss of 2.5% will increase the current demand by roughly the same fraction, but that is well within the rounding margin previously applied when estimating current demand.

So, this table of data suggests a twin core wire, where each core is not smaller than AWG 26 or 0.13 sq mm, should be able to cope.

--------------------

I should point out that I am only using data from one source, and that source does not state factors like the type of insulation, and hence its tolerance to elevated temperatures, etc. So there is lots of ways this estimate could be widely in error.

I am assuming the power source will be a controlled source, with a current limit set to a little over 1 A, that will provide protection in the event the wire insulation fails, or current demand exceeds 1 A for any reason.

As this is wire for an experimental project, which will be constantly supervised when in action by a competent person, only involves low voltage, and so on, I think it is worth testing. (It does not have the veracity or margins for general purpose application.)

It is common to assume wire is in 'free air', which is rarely the case unless it is to be strung from a pylon, but this is an exception!

Presently, I do not have an estimate for wire temperature - if I happen to find a calculator or estimate I will provide a follow up.

Of course, thin wires have limited strength, so this may be a consideration.

You may have better luck buying single core and making a twisted twin pair cable with strategically placed heat shrink to keep the wires together.

Ideally, look for a wire made of several copper strands, albeit very thin strands. I think they are made for specialist industries, but I have no idea as to price and availabilty for projects like ours.

----------

I hope this is helpful. I'll leave you figure out where to source such a cable, possibly even AliExpress?

Best wishes, Dave

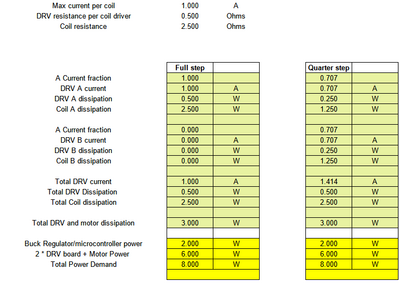

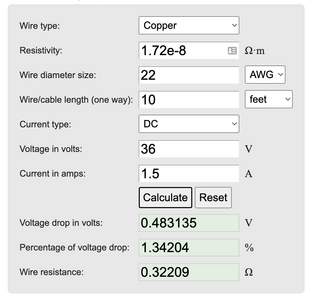

@davee @inq I used the calculator on the website Dennis quoted. All the numbers line up, 0.33mm^2 being the key spec. I used an average of 24v and 48v since I don't have a selection for 36V at 1A for 10ft 1way (calc is done for 2 way). The Vdrop% is 1.04% which in my engineering school is good. Using a different calculator, it says you should use 14AWG for 1% loss of 0.36V.

The bottom line is anything between 14 and 22 AWG will work fine with 18 being a nice midpoint.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

My personal scorecard is now 1 PC hardware fix (circa 1982), 1 open source fix (at age 82), and 2 zero day bugs in a major OS.

By all means, consider setting up a lab experiment to see if I am on or off the rails. And ask any more questions, etc.

Oh! I trust you implicitly. I wouldn't be doing it to check you. It's more that setting the A4988 to where it should be pulling 1 amp... never did pull that from the bench power supply. So even if I set up the DRV8825 to pull 1.5 amps, I want to see what is being pulled from the power supply and thus how much is going through the wire.

But all's good!

Thanks,

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

I hope this is helpful. I'll leave you figure out where to source such a cable, possibly even AliExpress?

Already have the 22AWG stranded. Seems like it might even be silicone insulation. I know I got some for something... but the memory fails. I'm glad that's the first thing to go. 🤣

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Part Trois point One ... 🤨

Thanks for looking this up, as I confess I didn't check this.

@inq's application is a little unusual .. for a start the wire is in the air ... and I don't think it needs to be conservative in the way that I would certainly advocate for a normal permanent installation or for a voltage above 50V. I have of course pointed out I am regarding this as an experiment.

You know I am normally pretty (some would say over) risk adverse, but in this case, I feel ok about sailing close to the wind, provide Dennis also understands and accepts the same

What he is interested in is minimum weight, and hence minimal gauge.

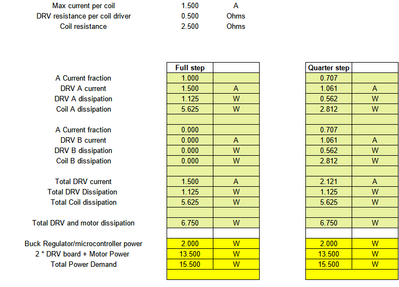

You say website Dennis mentioned, by which I assume you mean the powerstream.com one, so I looked at that.

https://www.powerstream.com/Wire_Size.htm

And the part I am using shows:

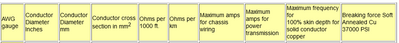

The header says:

The Maximum Amps for Chassis Wiring is also a conservative rating, but is meant for wiring in air, and not in a bundle.

Now, in this case, the wire will be a pair, which will reduce its ability to lose heat, and it would have been nice if there was some further guidance, but unfortunately there isn't.

The Tool Box guide I used gives current ratings for 'single' and 'up to three cores', with the latter around 65-70% of single core. Using this as a guide, 1A in up to 3 core, would be around 1.5 A single core.

So looking for 1.5A chassis wiring, on the powerstream.com table, 28 AWG is rated at 1.7 A.

I actually proposed 26 AWG, 2 sizes larger, that the chassis rates at 2.2 A for single core .. 65% derating for up to 3 core gives a rating of over 1.4A.

So it appears (by chance), the table I used is more conservative (ie suggesting thicker wire) than the one Dennis found.

The resistance per unit length of 133.85 Ohms per kilometer is virtually the same as 133 Ohm/1000m I used, so the voltage drop will be the same as well. The calculator gives 0.839 V for 10 feet, I had 0.8V for 3m

Interestingly, the powerstream table also gives a breaking force of 7.2 lb force, which is per core, so I guess that could be doubled for two core.

----------------

Dennis doesn't need the voltage drop to be low, (within reason), as the voltage drop is compensated for by the buck regulator and the 'pseudo buck regulator' nature of the DRV chip and the inductance of the motor, so losses of around 2.5% are of insignificant.

I don't think the 1 Watt of wasted power will significantly increase his electricity bill! 😊

-------

This remains an experimental project and these are just my estimates .. reality can sometimes show up flaws, but for the moment I am more concerned with the mechanical strength and other practical issues that have yet to be considered, so I am leaving my minimum wire core size recommendation at AWG 26 or equivalent.

Thanks for your input Ron ... it is valued and has helped to check part of my first attempt.

Best wishes, Dave

Hi @inq,

The current reading (and current limit setting) on your power supply is relevant to the 10 ft transmission cable ... but near meaningless to the current in the DRV and motor coils! (DRV means DRV8825, plus associated components on the small module)

I'll try to explain why, by estimating what the current reading on the power supply will be.

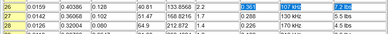

Assume:

- your part built system is powered up with one motor, and the motor is commanded to be at whole step position (this means one coil only is powered at '100%' DRV current setting )

- Current demand by buck regulator/processor and the 'logic' side of DRV chip is zero (an approximation to keep it simple!)

- Transmission cable is zero resistance, so no voltage drop (also an approximation to keep it simple!)

- DRV is set up and delivering 1.5A to the motor coil

- Motor coil resistance is 5 Ohms (A guess, hopefully higher than the real value)

- DRV board/chip has a resistance of 0.5 Ohms which is in series with the motor coil

- Since the motor coil and and DRV board are in series, the total load resistance is 5 + 0.5 = 5.5 Ohms

- V = IR ; So average Voltage across the Load = Current (1.5 A) * Resistance (5.5 Ohms) = 8.25 V

- And P (Power in Watts) = VI; So average Power = 8.25 (V) * 1.5 (A) = 12.375 W

- But Voltage from Power Supply is 32 V

- ... and power consumed by load must equal power supplied (Conservation of Energy)

- So again using P = VI; Power 12.375 (W) = 32 (V) * I (A) ; Current in Amps = 12.375/32 = 0.39 Amps

Summarising, although the motor coil current is 1.5 A, the power supply would only show 0.39 Amps

If the calculation was repeated with more accurate values in place of the approximations of zero resistance cable, and zero current buck regulator/processor and logic currents included, the power supply current would increase by a few percent at most.

This case is for one motor, double the power and power supply current for two motors. So (2 * 0.39 A) + small percentage for neglected power .. around 0.85A total.

-----------

Your motor will have a different resistance from 5 Ohms ... my solitary spare motor measured 2.5 Ohms, but they vary widely ... and this is the most significant term in the calculation. If your motor is less than 5 Ohms, which I have assumed it will be, the power supply current will also be less, even though the motor current is still 1.5A.

The DRV resistance of 0.5 Ohms is also a guess, but even if the real value is (say) 50% more, it will only add 0.25 Ohm to the total of the motor and DRV resistance, which is insignificant compared to the motor uncertainity.

----------

Although I stated that the motor had to be at a whole step position, I have previously shown that the magic of the microstep current control means that for all positions, both coils get a fraction of the current, and although the sum of currents can be as much as 1.414 times as much as the nominal setting (of 1.5A in this case), the power input remains constant, and hence the power supply demand will remain constant. That is power/energy is conserved, but current values can vary, because the associated voltages (P = IV) also vary to 'compensate'.

----------

All of this is applies to a stationary motor, powered to hold a position. Stepping the motor will reduce the power flow, and the power/current demand from the supply will (generally) fall. At high steppping speeds, other factors will start to change the maths .. I'm not offering any opinions on this regime!

----------

Sorry this is all thought experiment .. but the maths is only simple multiply and divide!

Obviously my suggestion of 26 AWG is a minimum wire thickness ... 22 AWG should give a good margin and will be stronger, although also heavier.

-----------

I am doing my best to estimate your requirements, but please do not regard these estimates as guaranteed or necessarily accurate .. As well as the likelihood I have made a mistake, the energy flow at higher stepping speeds and loads becomes increasingly complex, and I have never worked with these motors, so I may well be missing something. Simulations and estimates are nearly always helpful, mainly because they give some insight as to what is likely to be happening, but they should always be mixed with real measurements, etc., and when appropriate the simulations can then be improved.

I try to minimise unneccesary magic smoke, but occasionally a little magic smoke is a requirement!

Best wishes, Dave

I want to say with warm affection and admiration that you're like no other! 😊 Usually, I'm willing to drill down to China with you. And I know some day some EE doctoral student will read your Un, Deux, Trois posts and count their lucky stars and write to you and state how you saved their bacon. If my first blush with wiring was with UDT, I'd have been afraid to hook up my first bulb to a D cell... or burn my fingers when hooking up a 6V battery to a wire wrapped around a nail. I'm glad I didn't have the Internet back then. 🤣

Summarising, although the motor coil current is 1.5 A, the power supply would only show 0.39 Amps

I understand your analysis fine. I think my main issue that I was trying to get a handle on what wire I needed and what I could get away with. I have AWG30 and 22 available and I'd rather stick with those. I think @thrandell is using AWG30 for his umbilically wiring, but I assume he's using far smaller motors and he's only going about 4 feet. I have a good handle on the micro's and sensor requirements and pretty much discounted that they were down in the noise level anyway.

I was trying to get a worse case on the steppers. But... being commodity steppers the same model number seems to be all-over the place as far as specs. And those are marketing specs anyway... so not to be trusted. The vendor I purchased say 1.5A max capacity at 42V. Yet another vendor of the same model has it as 0.7A at 12V. However, this second vendor says it puts out 17W of horsepower. Assuming some inefficiencies, means it must use at least 20W of power which doesn't equate with the 0.7A/12V. Reading stepper datasheets might as well be playing darts.

In my final WAG of an energy tally, 2x20W/32V = 1.25A coming from the power supply and being carried across the umbilical. It's certainly better than the number coming from my stepper's specs saying 1.5A x 42V * 2 / 32V = ~4A. Either way, I'm way under the chart's value of 7A ability that @inst-tech found the definition that says basically because mine are in free-air, they fall under the in-chassis column.

In the final Fuzzy Inq Analysis... it's time to flip the switch and burn some fingers!

Take care my friend!

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Hi @inq,

Thanks for the kind reply. As you say, you were specifying 1.5A or more, and Nema17, which is hardly in the lightweight class.

As you now say you have 30 AWG wire, then for a quick smirk, I re-ran my spreadsheet with 2.5 Ohm motor coils and 1 A motor current ... Well you might have some motors like this in one of those many boxes of motors and stuff you have squirrelled away?

This takes the power flow (for 2 motors and 2 Watt budget for buck reg, etc) to 8 Watt, less than a third of the first estimate, and at 32 V from the power supply, this equates to 8 (W)/32 (V) = 0.25 Amp

And as before, the Powerstream table and calculator gives 'Chassis wiring' for single core in air, but not two core, so looking at the tool box data, up to three core, was roughly 65%-70% of the single core, so assume 0.25 A in single core is like 0.25/0.65 in two core = 0.38 A. (heating equivalent to current in single core)

So looking for wire to carry about 0.38 A in the Powerstream list ..

suggests even AWG 32 would be fine, albeit this table does tend be around +2 AWG more optimistic for a given current than the Tool-Box table, but of course the Tool-Box table stopped at 24 AWG.

--------

This suggested a 3rd try ... motor coil resistance 2.5 Ohm, coil current 1.5 A

And 15.5 W implies 15.5/32 = 0.48 A, which with 2/3 core effective heat increase = 0.48/0.65 = 0.75 A in the Power stream table.

Which is less than 0.86 A limit for 30 AWG in chassis wiring column.

So whilst this estimate is sailing close to the wind in a minor gale, it is not completely hopeless for the fearless or desperate sailor. Of course, such sailors do sometimes get into trouble.

Plus AWG 30 is rather thin ... breaking strain is listed at 2.75 lbs force (single wire).

If your motor coil resistance is equal or less than about 2.5 Ohms, then even at 1.5 A motor current, it might be worth a try, and at lower current it has a better chance.

-----

The opportunities and risks are all 100% yours .. take it cautiously and safely, building up a step at a time .. e.g. cable in air ... but probably along the bench, first with 1 motor, then 2 motors, maybe at 1A each, and so on.

Start with motors stationary .. if that works then stepping ... and so on.

Assuming you have a current limit control on your power supply, adjust it just a bit higher than you think it needs, but be aware that if it is a little too close to the average demand, then it might start tripping on transients.

Stop if the omens are not looking good at any time.

-----------------------

I just remembered, I haven't commented on capacitors at the bot end of the transmission cable.

My estimates are all based on 'average' currents, and you will be aware averages nearly always imply values above and below the average. This isn't usually a problem for the cable, but because the cable has appreciable resistance, an increase in current demand means the voltage drop increases, and hence the voltage that DRV and buck regulator get decreases .. and that can make them 'sea sick'.. well not literally .. but the electronic equivalent.

Hence, I suggest at least an electrolytic capacitor and a ceramic capacitor in parallel at the power input point to the bot, across the incoming power lines. Values are not critical, something like 1000 micro Farad electrolytic and 0.1 microFarad ceramic. Voltage rating must be greater than the incoming supply voltage ... 32V, I assume. I would hope for something like 48-64 V at least and even higher is usually fine... but if the voltage rating is too low, they can go out with a bang.

'Professional' circuits would probably have a more generous arrangement, but lets hope this is enough for your demands.

------------------------

Best wishes, good luck and take care, Dave

--------

PS I just Googled UDT ... is this what you meant?

😲

😳 You crazy guy you! I remember the trig proportioning from our train elevator dealings. I don't really think I'll be drag racing this or trying to do top-end speed runs, so I think the 1.5A per coil that the steppers can take will never be realized. I was just using those for the baseline till I actually have these in hand and do the some testing. The DRV8825 will have the heat-sync, but no forced induction, I'll adjust them for a maximum of 1.5A/coil. They will be in free air, so I don't think I'll ever hit the 2.2A even with worse case acceleration and worse case micro-stepping.

My custom bi-motor software driver does use micro-stepping and switches over to standard stepping like a transmission so I'll be hitting both coils at the same time.

Although I wasn't really expecting to actually doing Math to see if everything was in bounds... You know my philosophy... "Buy in bulk, save some money and let the smoke be free at will."

Buck converter usage. I think worse case usage of an ESP8266 draws about 250mA (at 3.3V) during boot up, but the steppers will never be running. During runtime, it falls to about 70mA.

The main part, I can really do some Math on is this: The motor/motor-driver combo doesn't really work on voltage. It monitors current and PWM's whatever the supply voltage is to get up to that current. So... although I know I can run the supply voltage anywhere from below 10V and upto the limits of the driver (I believe I saw 45V, but since I don't have above 32V, we'll say, more than I've got). I understand how using a higher supply voltage should allow the transmission wire to carry less current, I don't really see how to calculate the current the bot's going to pull... even knowing that it will run up to 1.5A, I don't know what effective PWM voltage that might be (or watts) to back calculate the what current the trans wires at 32V will be pulling. Am I make sense or just rambling?

@ing, Dennis... as an additional information for you on wire size and voltage loss on power distribution, As you know I worked as an industrial Instrumentation/Electrical tech for over 40 years, so I have a bit of experience with this sort of thing.. 😀

here's another link to a voltage loss calculator: https://www.rapidtables.com/calc/wire/voltage-drop-calculator.html that I think will help you in the future.. 10 ft should be no problem at your 36Vdc and 1.5 A using awg18, but if you want to decrease the drop more, you can go to awg16.

Industrially, we use Awg16 gauge for almost all of our analog signal (sensor) wiring. As you can probably image, some of the sensors can be up to 2000 ft away for the controllers that are providing a 24 Vdc @ 4-20 mAdc into a 250 ohm resistor so as to develop a 1-5 Vdc signal to the ADC of the controller, which has a 24 bit resolution! We routinely run awg16 >500ft, as as to keep Rmax , ( the total wire resistance ) within tolerance.

See the formula in this link: https://e2e.ti.com/blogs_/archives/b/precisionhub/posts/two-wire-4-20-ma-transmitters-background-and-common-issues for a better understanding of how this works.. Probably more information than you really need..but should answer many of your followup questions you may, or may not have...lol

regards,

LouisR

LouisR

Your previous post of the definition lead me to believe that I could pretty much count on the chassis wiring (AWG22 7.0A) versus transmission wiring (AWG22 0.92A) since the 2-wires will be hanging in the air. At least that is how I read the definition and your summary. The primary goal is to minimize that dangling 10' length of wire that the tiny bot has to drag around. Going to 18 or even 16 would be catastrophic!

I kind of intuitively (by dumb trial and error) that sending data over tiny wires any length is a no-no and remember your background and expertise in the area. I intend to do all data transfer via WiFi.

I hope to test the bot InqEgg in this configuration this weekend and see what the actual current draw is (with fire extinguisher in hand). 😆

VBR,

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

PS I just Googled UDT ... is this what you meant?

UDT - Un, Deux, Trois... but your find works too! 🤣

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Hi @inst-tech,

re . as an additional information for you etc etc

As always, your comments are accurate, informative and welcomed, but in this case maybe they are missing an important aspect of the target.

Because of the unusual nature of the load, namely a buck regulator and switch-mode style stepper motor controller, this application should be insensitive to voltage drop. However, it is sensitive to the weight of the wire.

My estimates and technical assumptions may well be flawed, but if they are roughly right, then it is possible to aim for the thinnest wires that can carry the current without overheating. This may well mean they lose (say) a Watt of power as heat to the atmosphere, perhaps 4% of the bot's consumption, but that seems a reasonable 'price' to pay in comparison to the advantages of thinner wires.

Of course, this is completely different from most power transmission systems, because a large proportion of power transmission systems are static, ground based and relatively insensitive to weight constraints, whilst wasting power increase running costs, increases need for cooling systems and so on, making efficiency the number one (or maybe number two, if capital cost is also an issue)

Hence, I initially suggested 26 AWG wire, and further thoughts are that if some limitations and constraints are acceptable, this might be further reduced to 30 AWG.

Of course, I may have made a cracker of an oversight, and will end up covered in egg, but that is the risk of sticking your neck out before research to confirm or deny a suggestion has occurred. I send apologies in advance, if this proves to be the case.

Best wishes and take care, Dave

Hi @inst-tech,

re . as an additional information for you etc etc

As always, your comments are accurate, informative and welcomed, but in this case maybe they are missing an important aspect of the target.

Because of the unusual nature of the load, namely a buck regulator and switch-mode style stepper motor controller, this application should be insensitive to voltage drop. However, it is sensitive to the weight of the wire.

My estimates and technical assumptions may well be flawed, but if they are roughly right, then it is possible to aim for the thinnest wires that can carry the current without overheating. This may well mean they lose (say) a Watt of power as heat to the atmosphere, perhaps 4% of the bot's consumption, but that seems a reasonable 'price' to pay in comparison to the advantages of thinner wires.

Of course, this is completely different from most power transmission systems, because a large proportion of power transmission systems are static, ground based and relatively insensitive to weight constraints, whilst wasting power increase running costs, increases need for cooling systems and so on, making efficiency the number one (or maybe number two, if capital cost is also an issue)

Hence, I initially suggested 26 AWG wire, and further thoughts are that if some limitations and constraints are acceptable, this might be further reduced to 30 AWG.

Of course, I may have made a cracker of an oversight, and will end up covered in egg, but that is the risk of sticking your neck out before research to confirm or deny a suggestion has occurred. I send apologies in advance, if this proves to be the case.

Best wishes and take care, Dave

@davee, @ing, Dave, Indeed, your probably correct in your assumptions, and It was just my intention to arm @ing (Dennis) with information that may be relevant in future projects.

I think the way to go is to use Wifi for transmitting instead of wire as Dennis has suggested that he may well use, but the battery capacity and weight may have an impact on the bots performance.. but then that's a another mater for the engineer to ponder...lol

regards,

LouisR

LouisR

@inst-tech 18 may be overkill, the original size @inq mentioned was 22 and it only suffers a 1.3% drop. See pic.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

My personal scorecard is now 1 PC hardware fix (circa 1982), 1 open source fix (at age 82), and 2 zero day bugs in a major OS.