I printed two rolls of metal glitter PLA when I first started printing. That tore through my first two nozzles! I've been using a steel coated every since.

Never used carbon fiber, but have threatened to many times.

Scott

If you touched it and it fell off, it was probably just what's known as "stringing", which is natural for when you're skipping spots, and going from high spot to high spot with air gaps in between. The nozzle is "drooling" while it's not printing. Sometimes you can avoid that problem, or, at least decrease it, by adding some retraction to the slice, and slow down the print just a tad to give it time to retract.

But, stringing is a normal part of 3d printing, and it's usually easily removed (except for on big parts, then it becomes REALLY annoying)

yeah i wasnt sure if it was part of the print or not it was a test file that came with the anet guess i could load it up in the slicer and look

Yea, most of the cheap nozzles are just brass, which is a really soft metal, and they get eaten up pretty easily

Since you already have the steel nozzles, give the carbon fiber a shot. I REALLY like it when the settings are right. It can come out really smooth, but, like I said, it eats brass nozzles for breakfast

Oh, I just thought of something. You guys should also order some .4MM drill bits. They won't always clean out a clogged nozzle (maybe 50/50), but, they will tell you if it's clogged or not

I keep the .4mm PCB bits as well as acupuncture needles. The needs are nice for using whilst the HE is on. Punch it up and twist and then pull to get a flow going from a small clog.

and it was recommended by Angus from Maker's Muse

i found his channel last night instant sub 🙂

Aye, he's good. And Thomas Sanlanderer. I also occasionally watch 3d Printing Nerd, who doesn't give tips so much as reviews, which I don't find useful as much as interesting. I'm never going to buy anything he reviews, so it's not really all that helpful

Now Bill on the other hand. Yea, I go out and buy a lot of the stuff he uses. I've got shelves full of stuff thanks to Bill

yup i just found it in cura and its enabled ty

You're welcome

But, just turning it on isn't enough. You've got to tweak it. Figure out how much to retract, and how fast, as well as changing the print speed.

Also remember that you won't always need it. On stuff with no air gaps there's no need for it

Glue sticks are your friend! I do like the clear though, as the colored ones show on the prints.

Steve,

Just a suggestion but maybe try the test file again that you used the sample PLA on. You changed 2 variables since your first good print. PLA and the file. This might tell you if the problem is with the settings for the new PLA or the settings of the file for the RPi case you are trying to print.

Pat

The most exciting phrase to hear in science, the one that heralds new discoveries, is not “Eureka!” (I found it!) but “That's funny …”

Author: Isaac Asimov

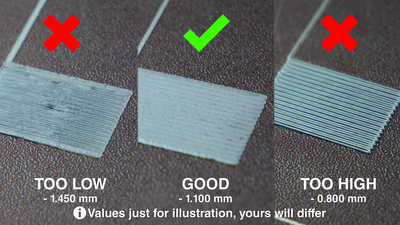

I've not got the same 3d printer but on my one I found it helpful to get the first layer calibrated properly by just to have a print consisting of a small square that just prints a first layer. I adjusted the first layer calibration by small increments during the print until it started to look just right.

Here is a pic showing what a difference small incremental adjustments make.

Got me some of that glue at Walmart. I was a big spender this morning! $0.33! Wow, this hobby is going to break me.

Now my question is, does the glue go on the glass before or after heating the bed?

Curious minds need to know. And what about leveling? Leave slightly less drag on the paper if a layer of glue is to be added, or is the difference negligible?

SteveG