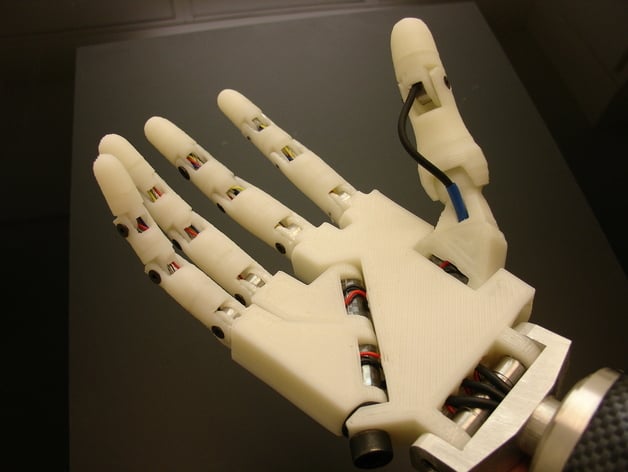

I want to build a couple of these:

I was going to build this the old fashioned way. But now I'm thinking that buying a 3D printer might be the better way to go. Although if I built it the old-fashioned way I'd probably make it entirely out of aluminum. It's not really a difficult machining job. Especially since most of the machining of the fingers would end up being done in fixture and jigs which would make the machining process go much faster.

So I'm undecided which way I want to go. 3D print in plastic. Or machining in aluminum?

Any opinions on this?

How long would it take to print out all these parts?

Here's the article on Thingiverse.

DroneBot Workshop Robotics Engineer

James

It would look great!!

The 3d printer is the best way. You can modify it. Design it to fit touch sensors and motors. I don't like the wire coming out of the thumb that way?

In my case I would have to pay someone to print the hand but first I have to get an arm to attach it to.

These young guys have the right idea 🙂

How long would it take to print out all these parts?

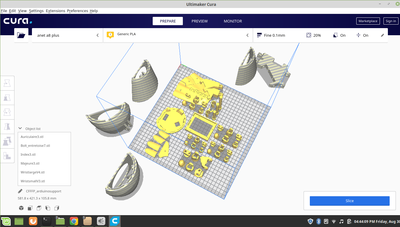

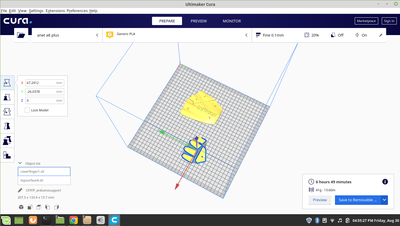

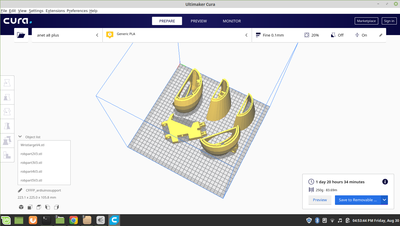

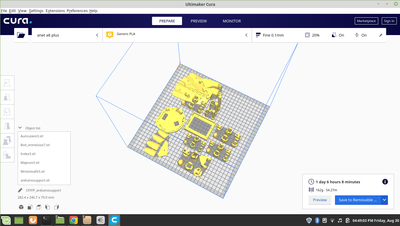

in my slicer for all parts it says 1 day 3 hours and 59 mins but it would take many sets of prints would have to do it in 2-4 sets of print because it has so many parts

EDIT

i rearranged it and it could be done in 2 seprate prints but i would feel better with 3 sets

it would be a fun one to make though even with out the wiring

sorry i was way off one min. im slicing it again

it would be a fun one to make though even with out the wiring

I'm not even sure how good this hand will be for robotics. I didn't read the whole article but from just skimming over it, it appears that this hand was originally designed just to be used as a still image for some sort of commercial? So I'm not even sure how well it will actually work.

There may be other 3D robotic hands that might be better. I kind of liked the looks of this one. I don't want one of those large bulky-looking squarish ones. They might work good but they don't look good. I'm also wonder if these prints can be scaled? My robot will be like a young child. So I would kind of like for her to have child size hands to match her body size.

I'm picky. ?

If 1`we had PM we could discuss the possibility of having you print me the parts for one.

I'd like to try assembling one and see how it works. If I like it I might suggest some modifications and then have a pair of them printed up in right and left.

I'm trying to decide whether I want to spend $200+ on a printer. Or buy $200 worth of aluminum to play with in my machine shop. Or just have someone else print these up for me?

So many choices.

I'm in no rush though. I don't even have the arms built yet, so no rush for the hands. But it would be nice to get a single prototype to play with so I can settle on a final design later.

DroneBot Workshop Robotics Engineer

James

and for me as i have been thinking about selling items i would say it would cost about $100 plus shipping

as i think about $1.10 - $1.20 per hour of print time for filament. print time, and wear and tear on the machine and cleaning up the parts would be a fair price (just saying as i have thought about making my money back on the machine and hopfully buying another one or 2) course all DBWS friends would get a nice discount. not trying to sell here just putting my thoughts out

and for me as i have been thinking about selling items i would say it would cost about $100 plus shipping

Problem there is after buying 8 items I could buy my own 3d printer.

My thoughts about a hand is maybe the ability to clip on different hands for different tasks?

and for me as i have been thinking about selling items i would say it would cost about $100 plus shipping

That's no doubt a very reasonable price for the amount of work and effort it takes to print it all out. The only problem is that to purchase 2 hands would already be $200 and I can buy the printer for that much. So I'd be better off buying the printer and printing them myself. That would also give me the flexibility of redesigning various parts and trying different things.

This is a problem with printers becoming so inexpensive to buy. A person can hardly make any money with them since if they charge a reasonable price for their work their products quickly approach the price of the printer.

I also like the idea of the aluminum hands. I might even be able to design fingers made of aluminum tubing. It's a lot to think about. It's nice to have the 3D printing drawing available though. I can always open those drawings with Fusion 360 and redesign them for making them out of aluminum. I already have a full machine shop with lots of metal working equipment. So in some sense it would be a shame not to put those machines to good use.

The only down side is that if I ever make videos about how I built my robots there won't be many people who could make aluminum hands from scratch due to lack of metal working machines. So in that case it would be better to offer them 3d printed plastic alternatives.

DroneBot Workshop Robotics Engineer

James

100% with you im was just saying for me and the loss of time on my machine thats what it would be worth to me and honestly being made out of aluminum would be much better of an idea and for a project like that it would be about $10 just for the PLA and more if you wanted it made out of something stronger.

My thoughts on building a general purpose human like hand is to use spring loaded closing so the fingers can passively take the shape of the object being grasped and motor used to open the fingers. Perhaps build them to fit a kitchen dish washing glove so slippage is not a big issue and sensors can be protected. A new skin would just involve a new kitchen glove. Maybe even use the glove to mould hand parts by pouring in a resin that would harden.

Just a thought

Maybe try not printing so many parts all at once. This way if something goes wrong you won't lose the whole batch

This way you also get to make small tweaks in between prints too

There's also a plug-in to let you load files from your git hub page too

I installed it, but, never played with it

My thoughts on building a general purpose human like hand is to use spring loaded closing so the fingers can passively take the shape of the object being grasped and motor used to open the fingers.

Yes, I'm a fan of a passive closing hand too. There are even ways to have the spring tension dynamically adjustable so you can choose whether to have it grasp tightly or loosely and still get a nice even grasp.

In fact, I've even thought of the possibility of using some type of hydraulic or pneumatic pressure to serve as the "spring" instead of an actual mechanical spring. This way you can have very fine control over exactly how much pressure is exerted. Of course, once you move to hydraulics as the pressure to close the hand then it actually makes sense to have mechanical springs used to open it. Either that, or double-acting hydraulic pistons. There's a lot of directions to go when designing a hand.

Just to get started I was thinking of being lazy and just using something someone else designed. But recently I've come to realize that it often pays to put in the work and design what you really like right off the bat.

Maybe even use the glove to mould hand parts by pouring in a resin that would harden.

That's another good idea. That way when the glove is placed onto the hand it will indeed be a perfect fit. I can't wait until winter get here. That's when I'll finally have time to work on this stuff. Assuming I get my heating system done on time.

Not sure if I mentions this, but a recent storm knocked a tree down that almost fell on my house. It's actually hung up on another tree that kept if from falling on the house. Unfortunately I need to take it down the rest of the way lest it ends up falling on the house after all. So now I'm being side tracked with tree service. I can't afford to call in the real deal. So I'll be starting up a chain saw here pretty soon.,

DroneBot Workshop Robotics Engineer

James