Hub dynamos used in bicycles usually have low nominal power (about 3W) and voltage (about 6V AC). Since the voltage is alternating, a rectifier must be used. But an ordinary bridge rectifier alone has about 1.4V of voltage drop, it is a big loss compared to the 6V input, where we usually want to have 5V DC out. I mention this to show, how challanging it is to effectively use this power source. Simple solutions just do not work here.

And so, there are many aspects which needs to be taken under account, beginning from the rectifier (at least Schottky diodes should be used), buck converter, MPPT (Maximum Power Point Tracking), undervoltage lockout, overvoltage protection and reactive power compensation. And it seems that reactive power losses have the biggest impact on the output power, which could be 2-3 (-4!) times higher than nominal, if this losses could be eliminated. So how to do that.

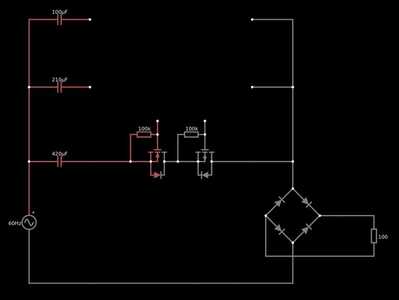

The only way i know so far is to use capacitors, connected even in series or parallel to the hub dynamo. But the optimum value of the capacitance is frequency dependent, and the frequency changes significantly with the speed (no, i am not OK with one compromise capacitor, i think the compromise is too big). A uC can measure the frequency and switch the best capacitor, but there is the question, how to switch? Relays may have a high switch rate and wear out quickly. A typical triac has a high voltage drop of 1.5 - 2V and that is too much. Any other circuits or approaches that you would use for reactive power compensation?

Why i want to build this... I believe that a power bank is not always an applicable solution on bike trips, at least not for me. It is just nice to be prepared for as much as possible.

Hi @j526,

I don't ride a bike, so I am not familiar with present technology associated with bikes. Perhaps someone else will come up with some better answers, but I will just make a suggestion that you might like to research further.

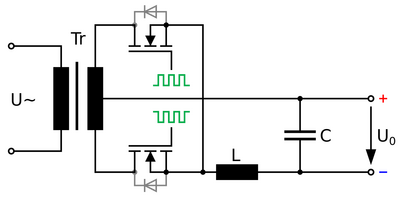

To improve on the efficiency of rectification (compared with diodes), the common approach is to use synchronous rectification. Oversimplifying, this means using a set of MOSFETs as switches to dynamically route the current to produce a current flow in just one direction. MOSFETs can have a very low resistance from drain to source when driven on, so the voltage drop can be much lower than with diodes. Of course, the MOSFETs must be dynamically switched in phase with the incoming power. This is commonly done in power supplies rectifying 'mains power' which is constant frequency, but might be more challenging with a bicycle, in which the frequency will change with the speed of the bike.

As for switching capacitors, again MOSFETs, driven in pseudo-relay style fashion, might prove helpful.

In principle, the other aspects you mention are probably relevant, but together look like a substantial body of work.

You may find it more efficient to use the system as a battery charger, rather than directly powering the lights. Of course, charging batteries, brings many other challenges, including safety.

I suspect a lot of people would be interested in your work if you can find a solution, but I think this might be a challenging project.

Sorry, I think that is the best I can offer at the moment ... perhaps others can make a better effort.

Good luck, Dave

@j526 I think the first thing you need to do is determine how much power you will be putting out and for how many hours. It may be a lot less than you are hoping.

As far as NOT wanting a battery, that is unusual. Perhaps I don't understand your requirements. If no battery then you will only be using power while riding and the existing mechanism is sufficient so what is it you want to do differently?

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

My personal scorecard is now 1 PC hardware fix (circa 1982), 1 open source fix (at age 82), and 2 zero day bugs in a major OS.

@davee , thank you for taking the time.

I think i will ask about active bridge rectifiers in another post. Although it sounds doable, it is probably not so easy to achieve. Is it not suspective that even today you are almost unable to buy an active rectifier IC or module? And even if, they are not really considered for low power applications, which i do not know why. As for the moment, i am OK with Schottky diodes, but this is definitely a hot point for improvement.

Maybe the professional solution for the bridge would be to completely ommit it and feed the power directly to a specially designed simetrically buck or buck-boost converter. I need to find the article where i read about it.

I can imagine another easy possible hack, and it is to use a transformer on the input side. If the voltage would be higher, even a few volts loss would be not that much in percentage. So now, how to obtain a high efficient low power transformer. I am afraid it must be DIY, but if DIY, who was cared about efficiency...

About MOSFETs switching on AC side, we can not forget the parasitic diode between source and drain. So this transistor is always conducting in one direction! And therefore, one transistor can not be used as on/off switch. But maybe two could be, at the price that in every direction the current is conducting via an "on" switched transistor and an "off" switched transistor (0.6V loss on the parasitic diode). But any idea on how to drive the gates from the DC side?

Hi @j526,

Sorry, I haven't really thought my answer through, as it isn't something I was personally interested in doing, but a Google based suggestion from Wikipedia, might be interest you, if you haven't already seen it.

https://en.wikipedia.org/wiki/Active_rectification which includes:

This includes a transformer, which as you say could be a step up type, and also arranges the FETs, so that for the conduction cycle, the current flows in the forward biased diode direction, and in the other half cycle, the FET and the intrinsic diode are both non-conducting.

Assuming the 'dynamo' you are thinking of, is an ac generator, which your question implied, then that transformer would presumably be fed directly. I don't know what frequency range the dynamo is likely to produce, so you would need to check the size and weight of a suitable transformer, though as power will be fairly low, this may not be a huge problem.

Sorry, I will leave you to figure out the gate drive, though I guess some trawling around switch mode power supply designs might prove illuminating.

You mention feeding directly to a buck-boost or similar converter, but my first reaction is that they all want dc feed, and this was about trying to reduce the diode losses ... but perhaps I am missing a trick.

Whether you could combine the above principle with a switch-mode converter, I wouldn't know.

I doubt if you will find any 'off the shelf' solutions - if it was that easy, the solution would already be on sale.

-----

Sorry, these are only speculative suggestions, but that doesn't mean you can't find an answer.

Good luck and best wishes, Dave

@zander what existing mechanism is sufficient?

The reason is, that there is almost no existing mechanism, taking a powerbank is just a work around. You must have the possibility to charge it on a longer way. What if you do not have it? What existing mechanism is sufficient to charge my navigation, so i can find the way home?

I think a kind of battery is anyway necessary. But the aim is to be able to charge it independently while riding. What i am expecting from that? Well, as much as possible. 5W at 20-25km/h would ba an interesting achievement, fully covering the power demand. I am sure that this should be possible.

How long can i ride? From sunrise to sunset, that is not the question.

I am fully agree that this kind of project is useless for the most people, at least it seems so for now. I have posted it because of the interesting technical challenges. But, how long do you think will fuel last in the world? Actually it does totally not matter if those are tens or hundreds of years, the fact is that our resources are limited and it would not be better if we just ignore it. I am convinced that the future of local mobility shall be seen in bicycles. Because they are just sufficient in most cases. And if you would be able to use your own energy to charge your own phone for your own needs, at least partially, would it not be just perfect? I hope that's enough philosophy... Lets stick to the technical details, please

@davee On the paper, this is a very good solution. This alludes to rectification circuits from the era of electron tubes where a bigger transformer was cheaper than two additional vacuum diodes. But nowadays it is rather hard to find a transformer with a double secondary winding. Anyway, the idea is not bad and i will think about it.

@j526 Sorry, I don't really understand what it is you want.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

My personal scorecard is now 1 PC hardware fix (circa 1982), 1 open source fix (at age 82), and 2 zero day bugs in a major OS.

Hi @j526,

Of course, the split secondary was used in the valve (tube) era, when wire was cheaper than multiple glassware, but it is still a current concept. In any event, I suspect you would need a custom transformer, so the need for a split winding is probably among the least of your challenges.

Good luck, Dave

@davee On a bike?

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

My personal scorecard is now 1 PC hardware fix (circa 1982), 1 open source fix (at age 82), and 2 zero day bugs in a major OS.

Hi Ron @zander,

A (small) transformer on a bike seems reasonable to me ... not sure what you are thinking ...

Best wishes, Dave

@davee I don't really understand what the OP is trying to accomplish. Why is a transformer needed if the standard generator already works.

From what I have seen, most new bikes use LED lighting and are battery (Lithium) powered as they last a very long time and are re-charged via USB wall wart.

I THINK he is looking at more primitive tech that is something a doomsday prepper would employ after society has broken down and there is no electrical infrastructure BUT I could be waaaaaay off.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

My personal scorecard is now 1 PC hardware fix (circa 1982), 1 open source fix (at age 82), and 2 zero day bugs in a major OS.

Hi Ron @zander,

My interpretation, which may be completely wrong, is that he is, or has been influenced by, a long distance rider ... which for some people, can mean a single 'ride' is a few hundred miles taking over 24 hours, and exceeding the span of a 'normal' battery lights, charge capability.

However, as you say, he has also made some more general comments beyond that, so overall, I am not sure of the total scope.

My impression is that 'dynamo' driven lights do not usually have battery back up when the bike is stopped, (although there may be one or more that have supercap backup, which is sufficient for a few seconds or so), and battery driven lights do not generally recharge by a bike driven dynamo. So I think he is looking for possibilities.

Furthermore, it seems that most bike generators are not very efficient, which means the rider is putting a substantial effort into producing a rather small useful electrical output, albeit there maybe one or two rather expensive alternatives, that are better than most.

I think it will be a difficult project, which I have already said. I am doubtful of the commercial viability, but this forum is not generally about commercial product development, and there may be an untapped niche market. I am not personally offering to support it, beyond my very limited suggestions above, as to where to look for ideas, but I wish him the best of luck if he wants to try to take it further.

Best wishes, Dave

@davee 24 hrs is nowhere close to the capacity of the Li battery's ability to provide lighting to a cyclist. They last a long time.

You are correct, the classic bicycle 'dynamo' has no battery backup.

I have no knowledge/experience with the efficiency of the classic bike 'dynamo', but if I had to guess, I agree it is likely not the most efficient design.

I didn't realize he had commercialization aspirations.

I STILL do not know what he is trying to build!!!

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

My personal scorecard is now 1 PC hardware fix (circa 1982), 1 open source fix (at age 82), and 2 zero day bugs in a major OS.

Hi Ron @zander,

I don't know if he has personal commercial aspirations as such ... he may be looking at this from an 'open hardware' or 'demonstrator' basis ... but I think it will need some custom components, circuits, etc., so I would see some form of commercial take up being required in the longer term, if the development was to have a significant influence.

I don't have a bike light to test, but I just measured the current taken by my personal headlight to be about 0.7A, which I would estimate to be about the same size and brightness as a decent bike light. It has 2x 18650 cells, each marked as 2.6A Hr, in parallel, though I expect that to be optimistic. However, if we assume that is a reasonable estimate for best quality cells, then this would give a maximum of around 7 hours, and probably rather less in practical usage, as the voltage drops, etc., whilst still maintaining good brightness.

Of course, this gives a lot more light than the old battery powered bike lights with filament bulbs, of the past, but I don't think their performance would still be regarded as acceptable.

Obviously, if you have a big enough battery, it will last a long time, and one might suggest 6-8 x 18650 cells, or equivalent, would an better answer to the problem. This would be a significant additional load to transport. It would certainly be a simple solution, but beyond that, I am not in a position to judge its viability.

Best wishes, Dave