I just noticed 2 listings for very similar solder. What is the real world difference?

The differences I can see on the labelling is 'Rosin Activated' on one, and 'Water Washable' on the other. Check the listing verbiage and the actual label verbiage.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi Ron @zander,

I have no knowledge of these particular solder products, but 'rosin' type flux (normally) leaves a residue which is not water soluble ... it isn't usually harmful to circuit boards and components, so leaving it on a board isn't a 'technical' problem .. but aesthetically, it looks messy and in the worst cases, it can make further work on the board an unpleasant experience. You can probably remove the residue with something like IPA (isopropyl alcohol), assuming there is nothing else on the board that will react badly with IPA.

Other fluxes are designed to give less residue problems, and the residue may be water soluble, which makes washing a board easier, especially in a commercial operation that will probably have many issues (eg health, safety, pollution) with using large quantities of IPA.

I presume the solders you identify have fluxes that fit these categories.

Best wishes, Dave

@davee Your reply prompted me to try a google search. It turned up this very good article that discusses ALL the types of flux. Now I know more, but still not sure what to buy. It's just my old brain, I will reread it a few times before I decide. https://blog.gotopac.com/2020/03/24/rosin-flux-soldering-flux-rosin-types-classification/

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi Ron @zander,

Probably either type of solder will meet your main needs. Personally, I like the more modern fluxes when dealing with clean, bright metals, etc., as they make far less mess, but the traditional resin/rosin based types tend to be more effective when dealing with tarnished copper and so on, that needs something with a bit more 'bite'.

Of course, you almost certainly have at least one resin based flux that you can use for those 'awkward' cases, that you can use with pretty much any solder.

And after you have studied the blogs & videos, etc, you will know more than I do!

Best wishes, Dave

@davee While everything you say is true, that is not my thinking since, at least at the moment, I am not doing repairs or even rework. My concern is that the solder will melt waaaaaay faster with the use of flux in addition to what may be in the core. Use less solder, and less use of the soldering iron/pencil thus preserving tip life and heater life. However, that may leave some flux behind. As you saw in the last link I posted, there are 5 types of flux. Each has its place but we can eliminate a few like Water Soluble (WS) as it is primarily designed for 'difficult surfaces' like stainless steel and has corrosion and conductivity issues. Rosin Activated (RA) flux is mainly for oxidized surfaces and needs cleaning ASAP. Rosin Mildly Activated Flux (RMA) contains the following weasel wording

The clear, soft material is often non-corrosive and nonconductive. Cleaning depends on the flux activity and the product in question for the selection of the appropriate solvent.

Note the use of 'often', 'depends', and 'appropriate'. I read that as it is NOT general purpose, it's a special case.

Old-fashioned standard Rosin Flux (R) is best for large wires that are clean and easy to solder. It may be worth having some for heavy-power leads.

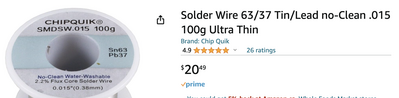

Finally, the No Clean Solder Flux (NC) is best for PCB work. While the residue can be left on, it can be cleaned with a 'compatible' solvent, most commonly Isopropyl Alcohol (IPA) but is a little more difficult to remove than RMA. This will be my daily use solder, primarily in 0.015 D but a size up and size down may be acquired at a future date.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.