Hi all.

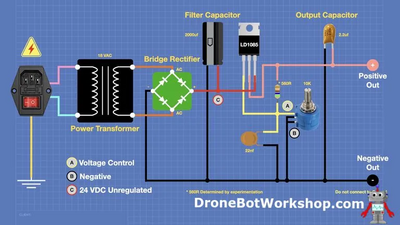

The last couple of days I've been working on my linear power supply, inspired by this site, I have followed the wiring diagram based on the picture that shows a LD1085 as the voltage regulator with a single 10 turn potentiometer, although I followed it to the T, it still has been a frustrating experience for me.

This is briefly what happened, I connected the positive out and negative out to my multimeter, check the voltage , it shows what it's supposed to show which is 24V (I'm using a 24VAC, 2 A transformer) and was so happy to see the voltage go down as I turned the potentiometer, so I unpluged the transformer and took a 10 minute break.

When I came back, plugged the transformer again but the DMM shows zero voltage, I checked all my connections, everything was fine up to the LM317 regulator, anything passed that point showed continuity but the display on my meter still shows zero.

The first thing I did was I replaced the LM317 with a new one and that was it, everything was back to normal ,DMM showed 24V and potentiometer worked just fine, but again after I turned the whole thing off waited a few minutes and back on, and again back to zero voltage.

So up to now I have damaged two LM317s and lost most of my confidence, tried to google how this was happening but got more confused and frustrated.

All the resistors, capacitors I used have the exact values as the diagram, (Except I used a 2.2uF metal Electrolytic capacitor ) which bill says it was ok to use. so why am I destroying my LM317s?

I thought I should order some LD1085s but could only find one vendor on Ali Express, and one here (Digikey) but I'm not sure the LM317 regulators are the problem.

Please let me know what you think I'm doing wrong here. any help/comment is appreciated. please if possible explain it in a way a newbie could understand.

Ken from Peterborough

I think it is going to be impossible to provide much help without seeing your project. You will need to make a few photos from several angles so that one part doesn't hide the wiring of another. At this point, the only logical conclusion is a wiring error but I am stumped as to what the possibilities are. Double-check all polarities, and the VR pinout. That's all I got for now.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi Ron, I understand how important it is to see what I'm working on, I will prepare the set up properly and take a couple photos, for now if you look at the diagram bellow( copy and paste from DroneBot Workshop), it is identical to the wiring I did which was a direct copy of it.

I just ordered 3 LD1085 regulators from Digikey, , I just tested the two LM317 and they both are dead.

I'll do what you suggested ,will double check the wiring, polarity, etc.

Thank you for your help.

d

Ken from Peterborough

@ddistrbd1 It is important to understand that Bill built the project, and I am fairly confident a few others did as well. Using both the logic of Sesame Street and Sherlock Holmes, I am afraid your project is either wired wrong or has a bad component leading to the destruction of other components. If you know of a 3rd alternative please fill me in. I know I have been in your shoes more than once and I understand how difficult it is to unsee something.

What if you disconnected some parts like the entire adjust leg? Power that up and down a few times to see what happens. Either (carefully) use your fingers to check for heat, or better still a laser temperature gun, to check every component. Then add a simple fixed voltage like 5V from a USB source or some other independent power supply and measure the output and check for hot components.

IF the 5V works with no problems, then very carefully REBUILD the more complex part of the project which is all the pots for the various outputs.

NOTE: I see from the LM317 spec it is only capable of 1.5A while the LD1085 is capable of 3.2A. Did you have an ammeter in circuit to measure the load current?

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@zander , I just realized my transformer produces 2Amp,the LM 317 can handle 1.5 amp . that's the most logical explanation in my untrained newbie hobbyist opinion. the LM317 gets the whole load of Amperage when the system is on.

Thank you for putting me in the right direction, the first thing to do is to measure the load current as you suggested, in all likelihood the poor LM317s were struggling to keep up for a few seconds but burned up soon after, my order of 3 new LD1085s are on the way, they should have been used in the first place, not the LM317.

Thank you again Ron.

Regards.

Ken.

Ken from Peterborough

@ddistrbd1 That sounds possible, but let's reserve judgement until the LD1085 is installed.

BTW, is Peterborough Ontario where you are from? I am in BC now but moving back to Ontario in June.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@zander , good advice Ron, I am optimistic the LD1085 will do the trick.

I don't live in Peterborough, but in a small town near it called Selwyn , good luck moving back to Ontario, I hope you bring the sunshine, good weather with you, I still have a foot of snow in my backyard but spring is around the corner.

Ken from Peterborough

@ddistrbd1 I hope so. I just ordered 3 of them from Mouser plus a few other parts to get this project done when I get moved.

We have liquid sunshine today. I don't mind snow, it's the bugs that will take getting used to again, have not had a single bite since crossing the Rockies.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi @ddistrbd1,

These kinds of problems typically involve considering the suspects, and checking their alibi's..

-----------

Of course, Ron @zander is right in suggesting you may have a wiring error ... checking is vital.

Fingers make resonably good temperature indicators ... if you say 'ouch', your problem is nearby ... but keep them on the low voltage side of the unit!

I'll just consider the other considerations

-----------

The most common reason for linear voltage regulators to die is overheating .. as they drop the voltage by inserting 'magic' resistance into the circuit, they must dissipate the heat generated by that resistance. But this depends on the current draw of the load.

(Ignoring the very small current used by the regulator itself ....)

e.g. Assuming 34V dc at the input to the regulator, 5V output to a load, drawing 0.5 Amps, then regulator dissipation =

(34 - 5) (V) * 0.5 (A) = 14.5 W

About the same dissipation as the smallest soldering irons ... which means a medium sized heatsink to keep it below (say) 70 deg Celsius

Note that this depends on the current draw ... if there is no load, then there is no dissipation...

So if they are dying, with no load, then this is not the cause, but you will need to keep it in mind in the future when driving loads that want low voltage and high current.

---------------

So if your regulators are dying, with no load, there are other concerns...

Overvoltage should be checked, but if your transformer is producing 24Vrms then the maximum voltage, ignoring diode losses, should be 24 X 1.1414 = 34 Vdc, which should be fine, assuming the parts you have are sound. Dodgy batches of parts are not common, but also not unknown.

--------------

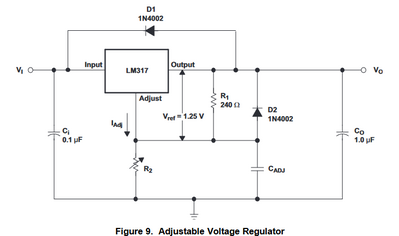

A sneaky reason is that the regulator is oscillating at a high frequency, which can also cause it to overheat. Here, I can only recommend you study the data sheet, e.g.

https://www.ti.com/lit/ds/symlink/lm317.pdf

which includes gems like:

and

Note that the input and output of the regulator have 'modest' value capacitors physically wired closely to the input and output. Their job is to improve the high frequency performance of the device and stop it oscillating.

---------

In addition, the schematic diagram above shows a diode connected from output to input.

This is to protect the regulator, if a large value capacitor is connected to regulator's output, either as part of the power supply or part of the load. The problem it is trying to solve happens when the input power is removed, so that momentarily, the voltage at the output, held up by the large capacitor, is higher than the voltage on the input - a situation that can rapidly destroy the device.

This would be my second 'most likely' suspect cause of your problem.

------------------------------

Note all linear voltage regulators have 'similar' considerations, but they do vary in important details .. use the data sheet for the type of regulator you are using.

------------------

I just realized my transformer produces 2Amp,the LM 317 can handle 1.5 amp . that's the most logical explanation in my untrained newbie hobbyist opinion. the LM317 gets the whole load of Amperage when the system is on.

The simplest comment here is No ... sorry your logic is flawed.

As discussed earlier in my sermon, the current flow depends upon the load.

Excess voltage from your transformer can certainly destroy the regulator, but if you have checked it to be 24 Vac rms, then unless your mains supply is subject to wild voltage fluctuations, which would mean the output would also have wild voltage flutuations, this is not the problem.

Having a transformer capable of supplying more than 1.5 A merely means that it can deliver more than 1.5 A IF the load demands more than 1.5 A ... the transformer cannot make it take more.

In engineering terms, having a transformer capable of delivering a (modestly) higher current than it needs to supply will proably mean it runs a lower temperature, be more efficient and be less likely to fail .. the downsides being it will be physically larger and heavier, and cost more to manufacture.

In practice, even if your load did demand a little over 1.5A, and the transformer obliged, the regulator would probably be fine, providing it did not overheat ... back to my (Volt drop * current) calculation earlier. And even then, it would probably survive a 'one off' incident, using its auto-shut off mechanism. The devices seem to be a bit like the proverbial cat that has 9 lives ... each overheating incident takes another of its multiple lives. Sadly, you won't find how many lives a proverbial voltage regulator has in the data sheet. I have changed a few in commercial equipment, suggesting the number of lives is finite.

---------------------

Hope this is informative. If you use a different regulator, use it's data sheet to 'adapt' my comments.

Best wishes, Dave

@davee , I had no idea you had sent a reply,, I must have deleted the notification by accident, I apologize for not getting back to you sooner.

In addition, the schematic diagram above shows a diode connected from output to input.

This is to protect the regulator, if a large value capacitor is connected to regulator's output, either as part of the power supply or part of the load. The problem it is trying to solve happens when the input power is removed, so that momentarily, the voltage at the output, held up by the large capacitor, is higher than the voltage on the input - a situation that can rapidly destroy the device.

This would be my second 'most likely' suspect cause of your problem.

I read your reply a couple of times to fully understand it(being a newbie and all) , I appreciate the way you explained your points .

The second most likely scenario makes a lot of sense, originally I did use a 2.3uF capacitor but in my last attempt with the new LD1085 regulator I went to 4.7uF(50v) which is still within allowed range but what I was missing (still am with LD1085) is the diode from output to input,.

Since my last post here I have used a LD1085 voltage regulator ( followed the same wiring diagram as before without the 1N4002 diode) and I did not have any issue.

Today I would like to ask another question if I may:

In the diagram I copied and pasted above, the rotary selector switch is connected to 3 trim pots and a 10 turn potentiometer, but they all are connected to one (set of) output, If I understand it correctly every click represent one of the trim pot value that I manually set at,, (3V, 5V, 9V), and the adjustable 4th.

I would like to change this set up if possible so each click goes to it's own output, which means I'll have one set of output for the adjustable, one for 5V , one for 9V and one for 12V? I do have small voltmeter displays to enable me to read each output , my question is:

A) is this change possible? do I need to have 3 LD1085 regulators in play instead of one?.

B) if there's a way, I don't know how to do it so the power supply works correctly .

So if you or any of the members read this, please let me know what you think.

Ken from Peterborough

@ddistrbd1 I will leave it to others to provide the details (@davee) but in general YES you can have multiple outputs, with each being a different voltage plus one variable. Just adjust the wiring to do that. You do not need any additional VR, but it could be built that way if you wanted to for some reason.

My understanding of what you want and how to do it is just connect each pot to a terminal instead of the selector switch. You no longer need the selector switch unless you want to only enable one output at a time.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@ddistrbd1 I will leave it to others to provide the details (@davee) but in general YES you can have multiple outputs, with each being a different voltage plus one variable. Just adjust the wiring to do that. You do not need any additional VR, but it could be built that way if you wanted to for some reason.

My understanding of what you want and how to do it is just connect each pot to a terminal instead of the selector switch. You no longer need the selector switch unless you want to only enable one output at a time.

Hi Ron, thanks so much for chiming in, , so it is possible after all eh?

I pictured it in my head just like you explained but the rotary switch would give me peace of mind since one output is connected.

Thanks again Ron, I'm going to test the new wiring , may have a couple more questions, hope to hear from you again.

Ken from Peterborough

@ddistrbd1 I like your idea, but I have a concern. Did Bill design the balance of the design such that using 2 outputs simultaneously will cause stress or even failure of some components? Without a deep dive I think the VR has lots of room but then maybe use separate VR's that are exact matches for the outputs. Also, maybe a toggle switch with a LED to show it's on is another idea. At the moment I am thinking of going that way. Thanks for the brain food.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Did Bill design the balance of the design such that using 2 outputs simultaneously will cause stress or even failure of some components?

I can only guess here but after watching that video about 20 times already, 😕,,, it seems Bill's decision was merely based on his need to have all 3 voltages connected to a single set of output , he even said that was his preference , any combination (within limits) was possible.

My main reason to have two separate outputs is to either connect one to a USB charger (the type used in cars) or connect it to C type outlet for charging phones, etc.

I can't stop thinking about all the possibilities, I need to take a break and look at my options before I start soldering.

Thanks again for your thoughts.

Ken from Peterborough

@ddistrbd1 We all have different work styles, but the beauty of that supply is it is easily modified to suit any need, I am thinking of using one of those rotary switches to control where the meter gets connected.

Just reacting to your comment about watching the video 20 times. Did you know there is a blog with each video? Click the more under the video, and usually, the first line is the blog. A newish feature is you can download a PDF of the project for use offline.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.