I'd like to understand the fundamentals of the cheap 30A ESC that are designed for RC airplanes and drones.

I think I understand the three leads going from the ESC to the motor are the different phases and each has a sine wave signal going across it to drive the motor. There are no other leads going to the motor. Does the ESC have circuitry that "senses" the motor's position or something back through the same 3 wires? I've heard the term EMF feedback, but don't really know what it is or if that has anything to do with this or not.

How is the same ESC able to work on various motors that have drastically different speeds based on their KV rating (1000, 1400 and 2200KV are common to this same ESC). How does the ESC know what's hooked up? How does it know what rate to send the sine wave frequency depending on how the prop is loaded climbing and diving or even what prop is attached?

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@Inq Dennis, this type of motor comes after my training and experience, but the term EMF feedback I understand. All that is, is the ElectroMotiveForce generated by the windings in the opposite direction so to speak. What that means in a practical sense is that you can 'measure' the amount to determine what the motor is 'feeling' in terms of net torque. That is an old off the cuff geezer's take, I suspect a quick google will give it to you in more modern terms.

I am shocked at the sizes quoted, 1000 to 2,200 Kv, that's 2,200,000 Volts? For the size of motors we hobbyists encounter, some are milli while some are whole volts and a few 10's of volts OR I have been living in a cave maybe.

I did watch a good video on brushless motors recently and I think it answered those questions, but with my brain all I remember is that I did see it. I will see what my search history tells me and get back to you if I have anything useful to tell you.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@Inq I think this was it, at least it was in my watch history

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@Inq At about 11:18 he mentions EMF being used for speed control versus Hall effect. That discussion goes on for a while, and a bit before that point for context. Hope this is what you were looking for.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi @inq,

Good to see you back!

Ron has kindly provided an intro and also a link to first YouTube I found ... I haven't played with these motors, but maybe can add a few comments from a mix of basic physics and Googling.

As a second YouTube, providing your link with the outside world holds up, is

//www.youtube.com/watch?v=F8l9Z1HGYcU

, in which the presenter designs a simple ESC for his submarine, which gives a different 'spin' on the same basic tale. Both videos provide some insight to how the back emf (basically the voltage generated by the motor as it spins) is used for controlling.

---------------

KV Rating is NOT kV rating ... the capitalisation makes a big difference. Apparently ....

https://dronenodes.com/brushless-motor-kv-rating-explained/

KV refers to the RPM per volt, when motor is unloaded. For a simple brushed DC motor, that is easy to follow ... but for a brushless one, the motor speed depends on both the applied voltage and the rate that the windings are energised and de-energised .. so I guess it can be experimentally determined by picking a voltage, starting with slow rate switching, monitor the rpm, and gradually increase the switching rate until the motor rpm can no longer keep up with the switching demand.

In general, the 'cheap' ESCs probably don't know the KV rating of the motor ... they will just try to match the incoming speed control demand ... and presumably fail if that demand is overambitious...

Of course, larger dedicated systems may well match the controller to the motor, and be more considerate to the motor.

-------------------

The videos explain how the rate of switching is synchronised to the actual motor position. You may note that in the videos, the MOSFETs supplying power to the motor, only switch hard on or off .. so the applied voltage is essentially a square wave. I suspect the 'more sophisticated' ESCs superimpose a PWM drive to make the effective current waveform closer to a sine wave ... I guess this would make it 'quieter and smoother', especially at lower speeds, but I can only guess if the difference would be noticeable in any given situation.

Best wishes, Dave

@davee Thanks for filling in some gaps in my explanation and knowledge, did NOT know about the KV difference, but makes sense now.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

I am shocked at the sizes quoted, 1000 to 2,200 Kv, that's 2,200,000 Volts? For the size of motors we hobbyists encounter, some are milli while some are whole volts and a few 10's of volts OR I have been living in a cave maybe.

Yeah! Me too when I first read it. In this situation, KV doesn't mean kilovolts. It's a theoretical maximum value of RPM verus input voltage. i.e. 1000 Kv on a 3S LiPo battery will deliver 3.7V * 3 * 1000 = 11,100 rpm.

@Inq At about 11:18 he mentions EMF being used for speed control versus Hall effect. That discussion goes on for a while, and a bit before that point for context. Hope this is what you were looking for.

As a second YouTube, providing your link with the outside world holds up, is...

I can't whine about that subject anymore... I'VE GOT STARLINK... and it rocks! I'm in their "Best Effort" category... that means, if it gets overloaded in my area, I get degraded. The worst I've seen is about 9 Mbps. But considering the best I've ever been able to get at home (even in Atlanta) is 6 Mbps DSL, the 100+ Mbps I usually get on Starlink is just stellar!

Anyway, I should have been more diligent using Google before, but I was kind of greasing the skids for what I really want to ask.

Thanks for linking those. I've watch both videos... The first was good enough intro into the second one that I got the gist... although, I don't think I'd tackle the EE side of that project. I'll stick to off-the-shelf ESC. But I hadn't thought about controlling that ESC with an Arduino. That definitely opens some ideas. 🤔

I like this on demand talking pictures thing. 🤣

Ok... I think I have it now. I was totally wrong about the sine wave stuff and that was what had me out in left field. I was having trouble understanding how it could be powering a voltage and receiving a "sensed" value. Now I see that they're "square waved" and that there is always one phase pair of wires turned off, yet are activated by the magnet and sends the signal back to the ESC. Got it.

I think I have my answer based on this thin understanding, but maybe you can say the words that will make it concrete.

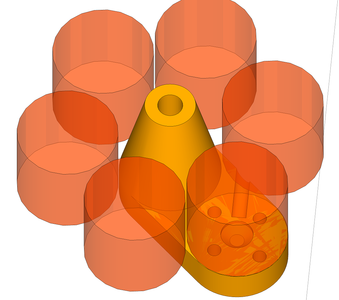

I'm looking to make a geared motor...

Each of the red translucent cylinders is one of these brushless motors. Each has a gear on it and the central, orange house holds the shaft, bearings and large gear. I realized I could place 1 to 6 motors quite easily. Since all motors are always synchronized mechanically, can one ESC be used (as long as it can handle the current) to drive all motors in-parallel.

I think the answer is No - UNLESS, I could make sure that all the motors are synchronized on the same phase when they are installed. Or... is that not even satisfactory?

VBR,

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Hi @Inq,

Compliments of the season, as it has just started Christmas day here .. hope the weather isn't too bad.

I looked up the DIY ESC approach, not because I expected you to make one, but I hoped it would give some insight into what was going on, in a way that the simpler guides that explain there are at least 3 wires and the rest is magic don't.

I am not sure, but I don't think you were completely wrong in expecting out of phase sine waves ... you probably won't find sine waves in the 'cheap and small' stuff, but I have a feeling the more sophisticated controllers may have a further level, so that instead of being 'hard on' for the period of time in each cycle, they are subjected to something like half a sine wave of the polarity appropriate to motor rotor position. However, the voltage of this sine wave would not be a nice curve, but rather a high speed PWM whose width wouuld give a roughly equivalent current flow to a sine wave. However, you probably don't need to worry about that.

As for your 6 motor question ... this is down to 100% speculation on my part, but I guess if your gearbox ensured that all the motors were permanently synchronised to be in the 'same' rotor position, then you might be able to make it work. (Or more accurately, I haven't spotted a reason why it can't work.) (You don't have a hope if they are out of phase with each other.)

Of course, the controllers depend upon being able to measure the back emf, as well as supplying the current at the right times, so it will depend on the resulting voltages and currents being consistent with the controller design ... and I rather fear the controller specification data will be 'minimal', so 'suck it and see' will probably be the only practical approach. I would start with two ... and build it up slowly...

That does leave me wondering if a single larger motor would be simpler and more predictable, but I am sure you have a good reason for wanting to take an unconventional route.

Best wishes,

Dave

My gut feel is also NO. If by chance motors 1, 2, 3 are identical in electrical characteristics AND mechanical characteristics, and motors 4, 5, 6 the same, then one set would fight the other set and worst case is either electrical or mechanical destruction of one set of motors or the other. In the very dark recesses of my memory I do recall seeing something like this that worked but no clue today. My google turned up a couple of interesting hits.

https://hackaday.com/2021/06/06/differential-drive-doesnt-quite-work-as-expected/

https://www.extrica.com/article/20973

https://blog.orientalmotor.com/motor-challenge-3-synchronizing-speeds-of-two-motors

Maybe there are possibilities in those links?

I have spent time around heavy steel mills and mining operations so may have seen one of these.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Merry Christmas All!

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

That does leave me wondering if a single larger motor would be simpler and more predictable, but I am sure you have a good reason for wanting to take an unconventional route.

It was more intellectual curiosity than real need and I knew this forum would be able to answer the question.

The actual problem that triggered the thought... I'm trying to design a counter rotating propeller. Since the rear propeller experiences drastically different conditions than the first set, I felt it would be better to have them independently driven by their own motor. That way the lighter loaded one would spin up faster and until they are both pulling for the power setting applied. If they're geared together, and spinning at the same speed, one is overworked while the other is not pulling its weight. Having one ESC in that case is clearly not going to work since they're not spinning at the same speed, so two ESC are necessary anyway.

So as you can see... conventional and simple are distant memories. 😎 😆

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq Viewed your video of the plane with a propeller, and I thought of what I use to work on back in my ol' Navy days ( 1965-1969)I.. A Drone Anti-submarine Helicopter (D.A.S.H.) It used a duel flex rotor system, one set turning CW, and the other turning CCW.. as you can see from the Link: https://www.ussnorris.com/dash ,

It had no tail rotor.. and was a remote controlled sub hunter.. first AV drone to enter service I think..anyway,

I thought you'd get a kick out of it..

Merry Christmas to you, happy ( better?) New Year!

Regards,

LouisR

LouisR