@will Do you think running the Raspberry Pi Pico will solve the issue?

I don't know, I've never used the model of NEMA nor the driver that you're using. The Pico will definitely give you a faster clock but I don't know if the driver and stepper are capable of running at the required speed (especially under load).

Anything seems possible when you don't know what you're talking about.

@clark77494 I am not expert at this to be sure, but doesn't this say the pico can do much more?

https://www.codrey.com/raspberry-pi/raspberry-pi-pico-pwm-primer/

Ron, the Stepper library doesn't use PWM. It sends pulses out and only uses digital pins.

I believe that DBWS has a video about using PWM to drive steppers, but I haven't explored the topic.

Clark, it may be worth taking a look to see if you think it might provide an alternative approach.

Anything seems possible when you don't know what you're talking about.

@will Ok, I thought that was what PWM was. I will go back in my corner now.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

I will go back in my corner now.

No, stay out here 🙂 Never hurts to have a second opinion.

Anything seems possible when you don't know what you're talking about.

@will One of the reasons for my confusion is the scope trace looks similar to the one posted by @clark77494

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@will One of the reasons for my confusion is the scope trace looks similar to the one posted by @clark77494

Yes, he's the one who posted it in this thread back at 12:28.

Anything seems possible when you don't know what you're talking about.

@will I was thinking a square wave is a square wave that's all.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Yep, that's why PWM is another alternative for driving a stepper. Gets a bit more complicated varying the speed.

Anything seems possible when you don't know what you're talking about.

@will Isn't the pulse width what controls that, I think they call it duty cycle.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@will Isn't the pulse width what controls that, I think they call it duty cycle.

Maybe, but I'd expect the frequency of the pulses, not their duration, to be the main factor in speed. As the speed increases for some drivers (and maybe the stepper motor too) you have to vary the mark/step ratio from 50/50 (for low speeds) to something like 25/75 (for very high speeds).

I tend not to push things to the bleeding edge of capability, so I'm not too knowledgeable at this end of the performance scale.

Anything seems possible when you don't know what you're talking about.

@will I thought it was the area under the curve that dictated the amount of power. It can be varied by modulating the amplitude or the width (duration). Unless there is something else at work here I am unaware of and that is a very real possibility.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@clark77494 That doesn't look healthy at all to me, but I am certainly no expert. That looks like it's stalled perhaps.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

It's not just a question of power. The rotation is caused by energizing electromagnets which push and pull permanent magnets, same as in a normal motor. The difference is that the stepper motor stops after every step (theoretically the field collapses), so a continuous stream of pulses is required. The faster the impulses are sent, the faster the stepper motor moves to the next step position.

So, raw power is important because the motor has to overcome static inertia to start with and fights against the change in rotational inertia as it speed up (or slows down). That's why acceleration is important, it allows you to start with slower (and therefore potentially longer lasting) pulses to overcome the initial resistance and then build up speed (by reducing the inter-pulse delay) while only having to overcome the gradual change in interim (as opposed to trying to jam it all at once).

Thats why you see weight lifters pulling on a train to move it instead of running directly into it at high speed 🙂

Anything seems possible when you don't know what you're talking about.

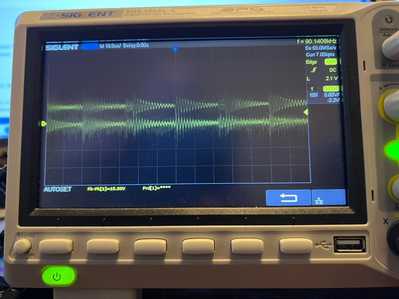

@zander The square wave that I am showing is when the motor is off and not under load. This is what the wave form looks like under load with the motor on.

Thanks, that picture is quite informative. It illustrates the stress and force induced by the driver's pulses and the counteracting force.

Anything seems possible when you don't know what you're talking about.