I have a soldering iron that works well, but I have trouble seeing the tiny components to be soldered. Even pin headers in holes are tough to see, much less surface mount parts.

Can anyone recommend a product that will help me see the components to be soldered?

I've heard of USB-powered microscope setups but don't know which one is worth using.

Or maybe there are better options?

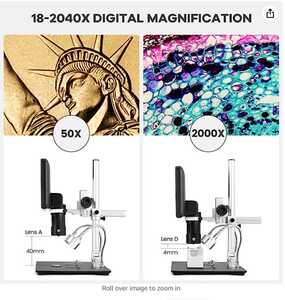

@wanaride67 The inexpensive USB powered devices are pretty much junk. This is what I use https://amz.run/7Z8a

Somebody who uses them everyday recommended this one https://amz.run/7Z8h

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

I also find that as I get older I have trouble seeing the component holes on the boards. I also use that head magnifier ( https://amz.run/7Z8a ). I did look into getting an electronic one but I found the focal length of the lens was short. The one on this site ( https://amz.run/7Z8h ) says it is only 40mm or about 1-9/16" from the lens tube to the work piece. This doesn't give you much room to work on any through hole type devices. Surface mount types would be better. I also don't need 50X magnification for the through hole parts. Just a thought to keep in mind.

@iceman To be fair, the last one is designed for working with SMD devices. The first one at the maximum 6X is usually too much except for those SMD parts smaller than a grain of rice. For component holes, I would not need much more than 1.5X or maybe 2X. Do you wear your glasses at the same time? I find that makes a huge difference.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Yes. I do wear my glasses at the same time. And that does make a difference. I usually only use a 2.5x or a 3.5X lens. I just need a little help seeing and still have room for soldering the components. I also have this electronic one ( https://www.aliexpress.com/item/4000129654391.html ). It cost less back in 2020. It has a decent focal length if you don't need the higher magnification. But it is not as convenient as having the magnifier on your head and it does time out and shut off.

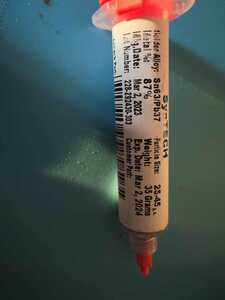

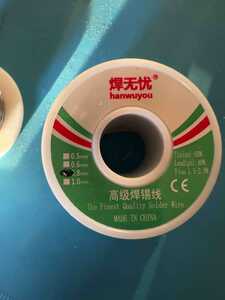

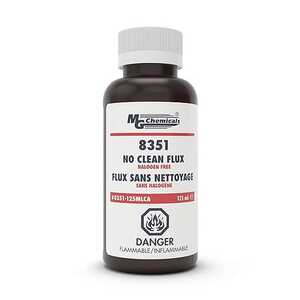

@iceman One thing that helped me was getting a pro soldering iron like this one https://amz.run/7ZRi and also get proper tips, the key tips are those with a shallow indent to hold solder, and the small wedge shape. I am including pictures of the tips I have (all genuine, lot's of fakes) plus the second half of the secret, flux. I was using the liquid in the squeeze bottle, but now have the pen which is a less wasteful applicator and some non fake flux that is all becoming stale dated very soon. I won;t buy any more until I am sure I need it. With the good iron and tip plus flux, I can solder super quick. Also get solder braid for when you make a boo boo. I bought a couple sets of varying sizes. Very easy to use and can also be used for certain soldering jobs. Check Youtube.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Yes. I use fluxes of different types depending on what I am soldering. I also use Dri-Wick (called Superwick by MG Chemical). I also have a soldering rework station. But I have not heard of those grooved tips. That sounds like a good idea. I use 63/37 solder as well as 60/40 depending on what I am soldering. Keep in mind I don't do much if anything with SMD chips. That Dri-Wick is similar to what I sold 50 years ago when I worked in an electronics supply shop. It is great stuff.

@iceman Sounds like you have a good handle on soldering. I don't mean to pry or get personal, but is your eyeglass prescription up to date? If it is, then I don't have any more suggestions.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

I suffer from Age Related Macular Degeneration in both eyes, and have Glaucoma in my left eye. Kind of hard when you can't see what you want to. Doctor said there are no prescription glasses you can presently use to help with seeing that missing detail. You can just make items larger. Usually use 4x reading glasses but the focal length is pretty short. I use a larger 5" diameter lighted magnifier with the glasses to be able to solder those small items. It is only a 2.5x magnifier with a 8" focal length (on a 45" arm). Not perfect, but it makes it a lot easier. Also, helps block the flux smoke from my eyes and nose.

Disadvantage is I have to clean a lot of nose smudges off the top of the glass.

/

RCC1

@rcc1 OK, I thought it might be something like that. You seem to have all the aids that generally help, but there may be one more. Check out 'borescopes,' especially the kind that uses a phone or tablet for its display. The advantage of one of those is there are a lot of them, and you may be able to find one with a decent working distance. The other advantage is they can be positioned almost anywhere fairly easily, and they are small enough not to hamper access for your soldering iron and hands.

Good luck.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.