I was using the ESP32-CAM board up till now, but recently I got a couple of ESP32 DOIT Devkit V1 modules. They are wider than the -CAM module. In a short search, I found others had discovered this issue.

When I place it in a standard breadboard, I only have 1 hole for connections, on one side. On the other side, I get no holes at all! 😬 😳 😡

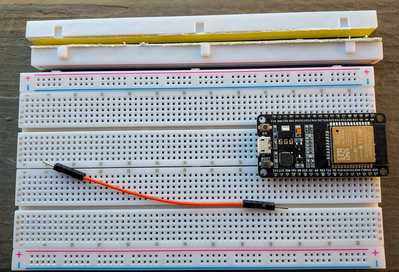

So I connected two breadboards together, side by side, without changing the rails at all. This wasn't very satisfying, but I looked around on YouTube and found some options. I liked one where you get two 830-point breadboards, remove the two innermost rails, then reattach the breadboards together; see attached photo. I can get plenty of holes for connections, on both sides. This is what I have for now, but it seems huge, bulky, and the two sides could detach, maybe, so I'm careful when picking it up.

What other options are there?

1. One guy used those tiny little breadboards, two of them, and didn't even try to join them together, just left a gap in the middle. I guess that works.

2. Another guy suggested custom PCBs, and had some photos, but I couldn't see any ESP32 boards in them. I guess if one designed a PCB they liked, and that fit the ESP32 development boards, it would be like having your own breakout module.

3. Adafruit, and some others, tend to have custom breakout boards for various microcontrollers or Raspberry Pi. Perhaps that's the way to go, though those custom boards can be expensive.

My question is: what do you use, or what ideas have you seen? Thank you! - John

In theory, theory and practice are the same.

In practice, they're different.

[snipped]

My question is: what do you use, or what ideas have you seen? Thank you! - John

Try tracing out the breadboard assembly onto a piece of cardboard, cut the cardboard to size and then hot-glue the pair of breadboards to the cardboard. I've done that to hold the breadboard and associated parts like stepper, power supplies and so on into the bottom of a box (cut down to about 2" high) to hold parts for a project steady enough to stop jiggling on the wires.

It works pretty well, but don't peel the breadboards first. If you leave the covering on the base, it's a lot easier to bend the cardboard off them when you want to re-use them for something else later. The hot glue peels off quite well.

Anything seems possible when you don't know what you're talking about.

I had the same issue, and still do I guess. My solution was to not go over the point in the breadboard that the two smaller breadboards connect at but over the dip in the same module. One side will have a single row available to work with and the other has none. I would pick the side I would be using or critically need and the other I would either ignore or I would run wires underneath and out the end(usually the VCC). Placing the ESP on the very end holes is suggested. I randomly placed one before and kept miscounting when laying down those wires. Dupont wire will not work for this. I will link to the type wire that worked for me below but I forgot where I ordered mine through. It is a good little assortment and I have actually been using them almost exclusively. Less fiddly and keeps a good connection. They are also great for linking things like the power rails.

Generally, I have been close to needing both sides but most projects I will only need one or 2 things from that side, like VCC pin to route out. Count from the edge for the pin you need, remove ESP and lay down the wire and replace ESP. It might also be useful to put a tape flag on it and label what it is is you think it will get confusing. White artisan tape is cheap and easy to write with a sharpie and clear to read.

I have seen breakout boards for ESP32 with screw terminals but I am amazed that I have not seen one that has a breadboard. I am always on the lookout for breadboards that have more than 5 min in a row but I have not had much luck. It might have to do with the various sizes and shapes that ESP32 comes in.

I might actually make one. I would be the reverse of the breakout board hats. A header to place the ESP32 and traces that lead to a small breadboard on each side. Because different variants have the power in slightly different places, if it were commercial it could not automatically link the power rails but for our dev kit c boards, it should be the two end pins. If anyone has any leads on a breadboard component that can connect to a PCB, let me know. I guess I'm off to Digi-Key to look for components.

Try tracing out the breadboard assembly onto a piece of cardboard, cut the cardboard to size and then hot-glue the pair of breadboards to the cardboard.

That's a good idea. I tried it, and think it will work for what I want, not super stiff, but enough to take care of the "wiggle." In fact, I just used the box that the Rex Qualis brand breadboards came in. Thanks for the tip.

I would pick the side I would be using or critically need and the other I would either ignore

Yeah, I ran across a comment somewhere, just like that, although the guy said it worked pretty well for the ESP8266, but now that he's working with ESP32, "it has interesting pins on both sides." 🙂

If it is just a few wires, I may try your idea of running them underneath the ESP32 module. It's pins are long enough that they should still make good contact with the breadboard.

By the way, I do know the style of "U Shape Solderless Breadboard Jumper Wire" you mentioned. They work great. A good selection came in my Discover Electronics Kit, and yes, I linked up all the power and ground rails 😉 After a while it did seem like the lengths I wanted weren't always there in the colors I wanted. So now I make my own.(*) I use 22 AWG solid wire; works great. I think that's the same as the ones in the commercial kit. They could also be as thick as 20 gauge, but no thicker, since I work with 18 AWG solid, and they're definitely not that. (I do not use the 18 AWG on a breadboard, since it's big enough to damage the little connections.)

(*) Bending my own U shape wires, I still don't get the lengths perfect, but at least I get to use the colors I like 😎

@will @madmisha Thanks a bunch for those ideas, and I'll keep at it. One thing at a time.

In theory, theory and practice are the same.

In practice, they're different.