Hi, my name is Bruno Fréchette.

I am a programmer and want to build an elevator at home with you help. I've been playing around with Arduino and ESP32 to acheive my goal.

Hi Bruno, welcome to the forum.

An elevator isn't a project that we run into much, sounds fascinating. I'm assuming that you are building it for someone with reduced mobility? Either that or you own a very tall house!

I'm guessing that the Arduino or ESP32 is to be used as a control unit?

Would love to hear more about it and know what stage of construction you're in.

😎

Bill

"Never trust a computer you can’t throw out a window." — Steve Wozniak

Hi, my name is Bruno Fréchette.

I am a programmer and want to build an elevator at home with you help. I've been playing around with Arduino and ESP32 to acheive my goal.

Welcome aboard, Bruno!

An elevator! For people? If so how many? Going up n down 90° to floor?

How big? Materials used? Any details yet?

Sure sounds interesting!

Thank you!

Have Fun,

Joe Lyddon

www.woodworkstuff.net

Hi @joelyddon,

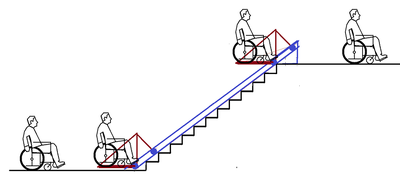

Yes a fully functionnal elevator for people. Two or three people will easily fit inside or a single wheelchair (me). I bought this house 4 years ago and haven't visited my basement yet. There will be 3 possibles access (elevator doors) and thoses are: the house main floor, the garage and of course the basement.

The construction contractor left a week ago. Therefore the structure is ready to receive the 2 inch square tubuling that is under construction by my brother in law that normaly build dumper trucks. The conccept will be similar to an XY 3d printer which include two threaded acme rod on each side with lots of bearings in each corners. These acme rods supports 9 000 pounds each and will be driven by two 14 nm steps motors / nema 34. The drivers are two DMA860H operated by two 48v DC power supply.

I was able to connect and operate the two motors with an arduino mega thanks to the workshp video. And thanks a lot about that video!!! Since I've decided to use ESP32s for the ease of communication with Access Point, Wifi and ESP-Now, the real question is: can I operate the DMA860H with an ESP32 at 3.3v or does it absolutetly require a 5v input like the adruino?

I'd rather uses ESP32 but in the case that 5v is required for the DMA860H then I'll be running my ESP32 with ESP-Now and communicate from my master ESP32 to the arduino throught I2C.

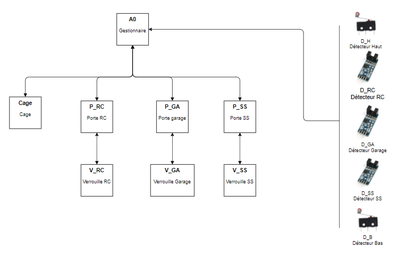

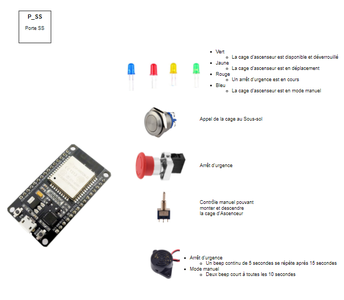

I am currently programming my doors, doorlock and elevator cage ESP32's and waiting for the tubuling to come in.

If anybody can answer my 3.3v compatibility question I would appreciate.

Keep in mind that the whole system will be operated with a 12v 100 amp/h battery. I will use ESP32 as an access point in the case there is no electricity and the router would therefore be not available. This mean I need something highly reliable.

Once the project is completed, I'll make pictures and code available here.

Anymore questions?

Sorry for my poor english writing.

AWESOME!

Are you going to have Floor Indicators above the doors on each floor with a little arrow moving from one floor to the other... Just like in the stores?

And you can Request it by pushing an UP or Down button too?

That sounds like a very interesting project!

How Fast will it be to get to 1 floor away?

I was surprised to see you're using Nema 34 steppers... a full load could be close to 800 lbs...

What will the LB limit capacity be?

Will your insurance cover any possible accidents directly connected to the elevator?

Thank you for your replies... Very interesting!

Have Fun,

Joe Lyddon

www.woodworkstuff.net

The only indicator available are gone to be 4 led with a yellow led indicating that the elevator cage is currently moving and a green led indcating that the elevator cage is arrived at your floor and the door is unlock. There will be a single button on each floor to call the elevator and inside the cage, there will be three buttons, one for each floor.

For the speed, I'll go for a 5 to 10 seconds between each floors and will adjust the speed while testing.

According to linear motion calculation, to lift 500 lbs, you're require to have a single 8nm motor. That is if I did not make any mistake in the understanding of linear motion. Since I bought 14nm motors, that should be sufficiant. But, in case there is an issue, I have two contention plans. Plan A: I've designed the cage to have heavy counter-weight on each side to compensate. Plan B, I already bought four nema 34 14nm so for now I'll use 2 of them but I have 2 more just in case there is an issue.

I plan to have gouvernement approve my elevator and therefore insurance would normaly accept it. That is far ahead.

Again, a big WOW!

Thank you very much for your replies...

We look forward to seeing more details as you progress through the project!

Have Fun,

Joe Lyddon

www.woodworkstuff.net

I would use a PLC, there's just too much at stake. IMO