I'm trying to figure out how to built a very basic thing, but my solution really sucks in every way possible.

I've connected a push/pull solenoid to a 12 V power supply so it is active until a thermal fuse breaks the circuit at 250 degrees Celsius. This releases the springloaded pin in the solenoid valve, pushing it out about 5 mm causing it to break a small ceramic tile.

But the power consumption while the solenoid is engaged is way too high, idling at around 10 Watt. I am trying to figure out if there is a smarter way to accomplish this task?

Perhaps it is possible to use a tiny amount of current passing through the thermal fuse and when/if is goes off due to high temperature this will activate the solenoid valve during a short period.

But if the thermal fuse cuts off the power to the solenoid it stops working since it no longer got any power to work with?

I'm a total noob, but it feels like there is right way to do this and not like I'm trying to do it now?

Here is a short clip where I've hooked up the solenoid valve to my power supply. You can clearly see the voltage, ampere and Watt on the power supply. At 12 Volt is uses about 1 Ampere.

Well. Take a look if you have 27 seconds to spare for my epic youtube movie, labeled by film critics as too long and lacking power and direction.

Here it is:

I'm hoping that someone will point me in the right direction. Common sense is telling me that the answer is some type of IC or simple transistor?

Thank you so much for taking the time to read this rather unclear message? But i hope you get what I'm trying to do?

Sincerely, Tony Nordin

@apeshaft

Why not just cut the power to the solenoid as soon as it fires. Presumably it will break the ceramic tile immediately upon striking it.

The solenoid appears to take all 10 watts to fire, but you can at least minimize the time it's sucking up that much power.

Anything seems possible when you don't know what you're talking about.

I'm trying to figure out how to built a very basic thing, but my solution really sucks in every way possible.

I've connected a push/pull solenoid to a 12 V power supply so it is active until a thermal fuse breaks the circuit at 250 degrees Celsius. This releases the springloaded pin in the solenoid valve, pushing it out about 5 mm causing it to break a small ceramic tile.

But the power consumption while the solenoid is engaged is way too high, idling at around 10 Watt. I am trying to figure out if there is a smarter way to accomplish this task?

Perhaps it is possible to use a tiny amount of current passing through the thermal fuse and when/if is goes off due to high temperature this will activate the solenoid valve during a short period.

But if the thermal fuse cuts off the power to the solenoid it stops working since it no longer got any power to work with?I'm a total noob, but it feels like there is right way to do this and not like I'm trying to do it now?

Here is a short clip where I've hooked up the solenoid valve to my power supply. You can clearly see the voltage, ampere and Watt on the power supply. At 12 Volt is uses about 1 Ampere.

Well. Take a look if you have 27 seconds to spare for my epic youtube movie, labeled by film critics as too long and lacking power and direction.

Here it is:I'm hoping that someone will point me in the right direction. Common sense is telling me that the answer is some type of IC or simple transistor?

Thank you so much for taking the time to read this rather unclear message? But i hope you get what I'm trying to do?Sincerely, Tony Nordin

You are very thorough with explanation of what you have. I sure do appreciate the video. We like pictures and moving pictures even better! I wish more people asked for help and were as thorough. What I'm not able to figure out is what you are wanting to achieve.

- My first guess is that you simply want to break tiles.

- Second guess, is that you want to quantify how strong a tile is. This ASTM standard might give you some ideas if you want to break tiles: https://www.astm.org/c0648-20.html

- Third, the unorthodox way of using a lot of power to heat up something maybe as an analog way (without microcontroller) time delay mechanism. I'm unclear what is heating up... I don't see the fuse in the circuit or what its being heated by it. I'm assuming you're heating the solenoid coil which makes it less powerful and could reduce its longevity. Also, I don't think thermal fuses have a very long life if constantly triggered. They're meant to be a failure mechanism, not a cyclic mechanism.

- So, I would ask for you to tell us what is the end-goal and if you are amenable or not to using a microcontroller. Is it 1 or 2 or is the end goal to heat something or a timer mechanism or is this some sub-system to some larger plot to take over the world? 🤣 We'd be in for that too.

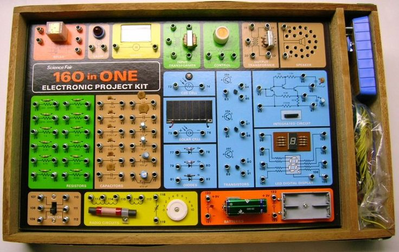

- Although way above my abilities, I think this could also be achieved with a capacitor, resistor circuit that slowly charges the capacitor (I think resistor size would set the charge time) and then dumps the charge... into the solenoid. It would use a tiny fraction of the power, none would be wasted on heat and it'd have a far stronger pulse to shoot the solenoid into the tile. But this is something, I think that falls under the expertise of @inst-tech or @davee. I remember doing something like this as one of the experiments that can be configured using one of these antiques:

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Hi @apeshaft,

You have already received some good advice above, so this is just a small addition..

RE: so it is active until a thermal fuse breaks the circuit at 250 degrees Celsius. This releases the springloaded pin in the solenoid valve, pushing it out about 5 mm causing it to break a small ceramic tile.so it is active until a thermal fuse breaks the circuit at 250 degrees Celsius. This releases the springloaded pin in the solenoid valve, pushing it out about 5 mm causing it to break a small ceramic tile.

I confess to be slightly bemused as to why you want to break tiles in this fashion, which might well have a bearing on the system requirements, but passing on that point for now, your description suggests that the 'breaking' is due to the spring force being unleashed, by removing the power from the solenoid.

This obviously means you need to supply power until that the moment it fires. If you must use it this way, then it might be possible to reduce the power, but only to a certain degree, which you will need to find experimentally.

It is common for relays, and I presume solenoids, to need a higher current to move to the 'activated' position, than is required to hold it in that position. For a simple experiment, apply the 12V to move it to the 'activated position'. Then slowly reduce the voltage (and hence the current) until the spring 'wins' and the pin starts to return the 'rest' state. By noting the voltage and current when that happens, you have a guide as to minimum power required to hold the solenoid. In practice, you would need to keep it powered at a little above this threshold if you don't want to risk accidental releases.

If this reduced power level is low enough to be acceptable, then it should be possible to devise a circuit that performs a similar function to your manual reduction, but that is separate discussion, having checked the principle.

-------

Alternately, as already mentioned, if the mechanical design is reversed, so that applying the power breaks the tile, then obviously power will only be required for about a second. Again, it should be possible to devise a different circuit, but depending upon the reason for breaking the tile, it should be recognised that if the power has failed for any reason, it will not work when expected. Whether this is of any consequence, you must judge.

Best wishes, Dave

Hi @apeshaft , As @ing as already alluded to the necessity of defining the criteria for how the circuit is to operate, ie: what is being heated, and how is the thermo fuse being used in the circuit.

To understand what the purpose of the circuit is, and what it's suppose to do is critical to designing a path forward, so with that in mind, could you please explain the purpose or a circuit schematic or drawing of what you are trying to achieve.

There are numerous ways to activate the solenoid to achieve your purpose, we just need to know what it is, and what sensory sources, ie: what are you measuring temperature of.. so that we can determine the best strategy to employ in the design..

kind regards,

LouisR

LouisR

@apeshaft I think it was Will @will who gave you the pragmatic solution. The video is very helpful. What the video shows that is wrong is that the solenoid remains energized after the return spring is fully compressed. The most simple change to your setup is to get rid of that fuse stuff and simply add a delay of maybe 1 sec before releasing the solenoid. If that works (no idea if spring is strong enough) then slowly change the delay to smaller values until you get a failure then back off 10ms or so.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

I'm building a very small furnace to try and produce a tiny amount of iron from iron ore that I've collected not far from where I live. The furnace will be very well insulated. The furnace will be round like a pipe or a bottle. The inside will have a diameter of about 250 mm (9,84 inches) the outer diameter will be about 350 mm (13,78 inches) and 15 mm of that will be an empty space with nothing but air and a K-type thermocouple probe that can measure temperatures from 0 Celsius to 1024 Celsius (32 F to 1875 F) and the outer most layer will be some sort of fire insulation that I haven't decided on yet.

On the top of the furnace I'm going to mount a ceramic plate. Above that plate I will have around 2 kg (4,4 lbs) of Ammonium phosphate (the same stuff that's used in most fire extinguishers). If something goes wrong and the temperature in the space where the temperature is placed the zelenoid will crack the tile and dump all the ammonium phosphate straight down on top of the furnace core and in the space between.

I'm going to use this furnace in my bed while I'm sleeping... No, wait! That would be stupid! I'm going to use it outside on my lawn far away from my house or any other building. The tile cracking feature is just to be super safe and avoid burning down my house. Using water will probably cause it to explode. Here's Emily Watson in a scene from the HBO series "Chernobyl" with a great explanation:

My furnace will run for hours at a time depending on what I'm trying to do. Using it as a kiln to make pottery from clay, or smelt some other type of ore or scrap metal. Making glaced pottery can take up to 24 hours in total. So it's a safety precaution.

And I also think it's a fun little project! 🙂

Since iron ore (unlike enriched Uranium) isn't normally exothermic in quantity, it seems that it should be enough to just stop whatever is supplying the heat to your furnace. It will start cooling immediately and there's no chance of a China syndrome event.

Dumping a fire extinguisher's contents into the area seems strange, there is NO fire, just too much heat.

Anything seems possible when you don't know what you're talking about.

@apeshaft Since you said you would be using this extremely dangerous device outside on your lawn for up to 24 hours, what is preventing some other person especially inquisitive children, from a potentially serious injury?

In the small town where I live, we used to have an art workshop, fairly big, maybe 50ft by 100ft. The building has since been taken down, but when it was in operation, we had at least one kiln in there. The kiln was probably 50% or more insulation (inside layer fire brick, outside unknown encased in something else. We could leave it unattended as the room and the building were locked if no one was there.

I suggest you do some googling on the subject to get a safe workable solution. I would not worry at all about a tile breaking safety mechanism, all that is required is to turn off the heat source as Will pointed out. We had switches by each kiln, and a master emergency off at the doorway to the room.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

I'm building a very small furnace to try and produce a tiny amount of iron from iron ore that I've collected not far from where I live. The furnace will be very well insulated. The furnace will be round like a pipe or a bottle. The inside will have a diameter of about 250 mm (9,84 inches) the outer diameter will be about 350 mm (13,78 inches) and 15 mm of that will be an empty space with nothing but air and a K-type thermocouple probe that can measure temperatures from 0 Celsius to 1024 Celsius (32 F to 1875 F) and the outer most layer will be some sort of fire insulation that I haven't decided on yet.

On the top of the furnace I'm going to mount a ceramic plate. Above that plate I will have around 2 kg (4,4 lbs) of Ammonium phosphate (the same stuff that's used in most fire extinguishers). If something goes wrong and the temperature in the space where the temperature is placed the zelenoid will crack the tile and dump all the ammonium phosphate straight down on top of the furnace core and in the space between.

I'm going to use this furnace in my bed while I'm sleeping... No, wait! That would be stupid! I'm going to use it outside on my lawn far away from my house or any other building. The tile cracking feature is just to be super safe and avoid burning down my house. Using water will probably cause it to explode. Here's Emily Watson in a scene from the HBO series "Chernobyl" with a great explanation:

My furnace will run for hours at a time depending on what I'm trying to do. Using it as a kiln to make pottery from clay, or smelt some other type of ore or scrap metal. Making glaced pottery can take up to 24 hours in total. So it's a safety precaution.

And I also think it's a fun little project! 🙂

@apeshaft, Well now that we know what you are intending to do..we can perhaps prescribe some solutions to your project..First of all, as @will has suggested, cutting off the fuel supply to the furnace would be the first thing to consider. That can easily be done, and unless there is a fire in the space between the furnace core and the outer insulation, this should be sufficient.

Question.. what are you using for a fuel source to heat the furnace ie: natural gas, kerosene, electric element, or other material? The reason I ask is since you already have a type 'K' thermocouple to measure the furnace temperature, this can be used to activate a shut-off mechanism for the fuel supply. The practicality of using the ammonium sulfate as a fire retardant can work, but as @will as eluded to would be unnecessary, but could be a backup if you wish. A simple drawing of what you have in mind would also be helpful..

looking forward to seeing your project come to frution..

regards,

LouisR

LouisR

A big thanks to everyone that's been posting in this thread.

I don't know anybody that's intrested in electronics and strange little projects IRL. So just to be able to post my first thoughts and get feedback is tremendously helpful. It's difficult to get out of your own head and rethink projects like this one if you alone and so easy to get totally stuck in you thinking.

But, here's an update!

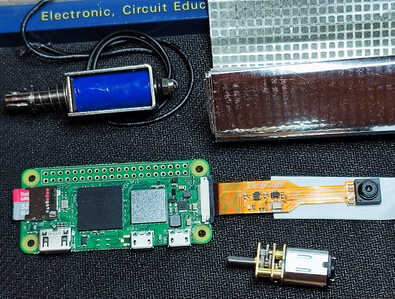

I've decided to start from scratch. I will use a Rasberry Pi Zero 2 W and the Zerocam that can be connected to the Rasberry Zero. Instead of one temperature probe there will be two of them. One will be placed in the center of the kiln with a display showing the temperature attached on the outside. The other K-probe will provide temperature data to the Nano.

The Nano will also control the Zelenoid and activate it if the temperature reading from the K-probe gets to high. So it will not use any power unless it's activated.

The Zerocam module will be mounted directly outside of the the heat chamber by letting it look in through a small hole plugged with a small piece of glass that can handle really high temperature.

On the picture you can also see what the Zircofoil heat shielding material looks like.

By using a Rasberry Pi Zero 2 W with a camera I can use the camera to see what's going on inside in real time. And access the video stream anywhere from the Internet since the Pi Zero 2 W is equipped with Wifi and Internet connection.

As an alternative to the zeleonid I've also bought a small electric motor with a built in gearbox to crack the protetive tile.

The iron ore that is stuck to the magnet will be crushed into much smaller pieces before going in the kiln.

And the setup will be childproof by using deadly high votage fencing and claymores. No, wait! That would be murder. But there are no kids around where I live and I'm going to place it in a locked shed or steel box or something like that. Ok, I don't want any children to get hur, but I also don't want anyone stealing it either!

One more question since English is not my first language, its Sveeeedish, Ja ja, Oooo ja!

What is the english word for the small cup used when you want to melt some metal (smelting some metal?). It is made out some super heat resistant material.

NVM, found it! Its called a crucible. But once agin, Thank you for all your input!

Since iron melts at 1800C and your camera will self-liquify well below that temperature, I'd suggest that you do some heat-testing with the camera before fully integrating it into your plans.

Anything seems possible when you don't know what you're talking about.

Since iron melts at 1800C and your camera will self-liquify well below that temperature, I'd suggest that you do some heat-testing with the camera before fully integrating it into your plans.

Good place to attach a thermal fuse on th outside of the glass. But I've worked att places like Sandvik out side Gävle and a large Oil refinery outside Gothenburg. It could get really god amn hot whil working in those places. But dtstilling oil or produce special metal alloys at Sandvik. Both places small glass on the hottest part in the factory. It was the, maybe it still is?

You had to slide a metal ring to the side and look through a very heavy duty window glass to see hat everything was ok. It is called an occluar inspection, done on site next to the machine to be able to get a good view what's really going inside.

So with a chunk of that type of glass the cero cam will be just finee with no riss that heat will destroy ane prevent the zerocam frosm overheating an stop working.

This version gotta be better than my first idé of on how to accomplish. The first prototyp was made from mostly canned soup, spare change, flat earh supperts andprobably some wires and somewhee around 3 - 90 million 9 Volt batteris. his just gotta be better?! Right?

Hi @apeshaft,

You appear to have some firsthand experience, but be careful. I am not disputing what you saying:

You had to slide a metal ring to the side and look through a very heavy duty window glass to see hat everything was ok. It is called an occluar inspection, done on site next to the machine to be able to get a good view what's really going inside.

So with a chunk of that type of glass the cero cam will be just finee with no riss that heat will destroy ane prevent the zerocam frosm overheating an stop working.

But I assume, when looking inside, you are are only doing it for a few seconds. The infra-red rays (in particular) from the furnace will be invisible to your eye, but they will be heating it and risk causing damage. However, if the period is very short, the rise in temperature may be relatively "small", particularly as the eyeball contains a fair mass of water. which will help to absorb some of the energy. (NB I am not saying what is safe, just pointing out some simple physics that may account for your experience.)

However, if a camera (or your eye) continued to look at the furnace for an extended period, the cumulative effect might cause the temperature to exceed the safe limits. (There could be other damage mechanisms as well.)

Please note, sorry, I have no idea what 'short' and 'extended' times are in terms of seconds. You will need to assess these yourself. Obviously, the shorter the time, the lower the risk of overheating. But the responsibility for any loss or damage, including to your own eyesight, is totally your responsibility.

-------------------------

You may be able to reduce this effect by placing an infra-red filter in front of the camera lens. This might be in addition to any IR coating built into the camera optics. Sorry, I have no idea how successful or robust this will be.

You may consider including a moveable metal shield, similar in principle to the metal ring you describe, to shield & protect the camera when you are not actually viewing the camera image. This might be remote controlled using a second solenoid or similar arrangement. You may need to ensure the shield is only open for a short period of time, followed by a (longer) period when it must be shut, to allow for any heat to dissipate.

----------------

Your project is interesting, but also encompasses more risks than most projects on this forum. I do not have the relevant knowledge and experience to assess the risks of what you are proposing, and hence you must take all of that responsibility. Everything I have written is only a suggestion for you to consider - it is NOT a recommendation, NOR am I saying it is safe.

Good luck, please take care and stay safe, Dave