@davee On a more serious note, I looked waaaaay back in the topic to see if I could uncover some values. But first, the spec sheet for the large digit driver I am looking at has 15 beside each resistor, but the notes under that uses 20ma and .4V resulting in a 20 ohm resistor, HOWEVER they go on to say in testing 11 to 14 worked well. I am not sure how that ties in with your explanation.

I then looked at the OP's early posts and see a datasheet. I find it quite confusing, in one place it says 20ma but I can't read the label, and in other places it says 50ma continuous and 80ma peak. I am not sure which of those you use for manual calculations (I always use several online calculators (why are they always different???)) but whichever it is, that gives you the value of resistor to use to drop the voltage from 12V down to whatever the LED needs. It doesn't sound to me to be that difficult, and unless a ridiculously too small value was used I don't see any great amounts of smoke.

What I would do is put a buck converter between the 12V and the board to reduce the voltage enough to give 'normal' voltage drops across the resistors. I wonder what result I would get with one of those on-line calculators?

ALSO, I don't see any reason why Louis(@inst-tech) solution wouldn't work. I think his part is cheaper as well. I see it available on eBay, DigiKey and AliExpress.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi Ron,

Very drole 😀 😀

The chip is probably fine ... I didn't criticise it.

------------------------------

Please remember, LEDs are forward biased diodes, so that the current increases exponentially when the voltage is increased. This means a tiny increase in voltage will result in a large increase in current.

Hence, they must be supplied with a 'current controlled supply', not a 'voltage controlled supply'.

The chip was not designed to control the LED current. (The same is true for all the alternatives I came across.) The designer utilising the chip is expected to make suitable provision for current control.

In reality, this nearly always means there will be a resistor in series with the LED, so that the effect of small changes in supply voltage only cause modest changes in the current flow. To be effective, the resistor's resistance value must be high enough to drop a substantial voltage.

If this is not the case, a small reduction in supply voltage could result in a large brightness reduction, or even no light emission. Natural variations between the segments could result in the wrong number being observed, if one segment needed a slightly higher voltage than the others.

-----------------------------

Hence, the SparkFun board I was less impressed with, due to the choice of 15 or 20 Ohm resistor.

I don't know the background to the design, but the SparkFun 6.5" LED display apparently needs almost 12V (to work at all), and they chose to specify a 12V power supply, which meant the series resistor had to be a very low value.

The chip had a rating of up to 33V for the LED connections, so that was not a reason for picking such a low voltage supply rating.

Had I 'designed' the Sparkfun board, I would have picked a higher voltage supply requirement - say at least 13V, probably 15V would be convenient, and adjusted the resistors values accordingly.

Of course, this is just my opinion, so feel free to disagree.

-----------

And the resistor values are not suitable for the 3.5" LED display, which is obviously fixable, providing you realise you need to, and know how.

I do not have a 'great hate' for this board ... I merely thought, based on UK indicative prices, there were better value options in the circumstances.

Best wishes, Dave

@davee Ok, I misunderstood you, I thought you were saying there was no way to make it work. I am not sure I would use the Large Digit board either just based on price, and it is a simple matter to use the solution Louis (@inst-tech) provided or similar.

The Large Digit board is intended to work with the 6.5" LED and I imagine that draws more than 20ma thus different voltage and current. I think the OP knew he would need to make an adjustment for his 3" LED.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@davee Hi Dave, First of all, thanks for your efforts in trying to advise me on what could work for my project. The fact that you actually created a mock up(!) to try and get to the bottom of some of the possibilities is really appreciated. I wanted to answer a question from another post of yours, where you wondered why I chose the board I did, along with some other clarifications. I will try to be brief, but I'll probably fail. I thought of this project, and began to research what I needed to acquire to make it happen. (This was with zero experience, or even being aware that these large pizza and a coke priced computers even existed). Within 30 minutes of reading about them, I placed an order for the R-4. I guess it was that it was a new version, which had finally been released after the R-3 had been used for 10 years to build robots, and just about any small project that one could want, I mean, what could go wrong? So, yes, I just jumped on one without researching others, so that's my bad, but even if things didn't work out, I wouldn't have to go to divorce court about the outlay for the board, plus all the other goodies and hardware I have bought (so far). The other thing concerns my ability to bring this project to fruition. I have experience with pc board wiring, in fact, my first job out of high school was troubleshooting small electronics, such as communications and audio equipment, and in those days it was many times soldering defects on the pc board. Trouble is, the things that you and others are discussing is currently beyond my understanding, having either never learned it, or, on a more serious note, can no longer recall it. So, yes, if I have a parts list, and some guidance/suggestions about the physical connections needed to be made be made, I'm fully capable. Lastly, the same is going to hold true for the coding that is involved here. I've never coded anything, and in fact, as I write this, I'm not sure if my R-4 can be taught to do what I need it to do, or would another board do it better? One step at a time for now. Again, I much appreciate the help and interest in my small, just for fun project, and I'm sure you're all glad that I'll stop talking now.

Hi Ron @zander,

Once again, our posts have crossed in the ether. I'll try to pick up on your latest message.

----------

I have just explained that the LED's current is related to the exponential of the voltage of the applied voltage.

For my tests, the system with a variable voltage supply, with a 510 Ohm series resistor in series with each segment of my 15mm digit. Each segment has a forward voltage drop of just under 2V. I addition, the driver chip Darlington transistor had a voltage drop of around 0.6V to 0.7V, So the resistor drop was approximately (Supply Voltage - 2.7V),

For 1 segment, I added 3 discrete LEDS in series, so that there were 4 LEDS. The LEDs were blue, forward voltage drop of about 2.7V per LED. Hence, resistor drop was approximately

(Supply Voltage - (2 + (3 * 2.7)) = (Supply Voltage - 10.1) (at a current of a few mA)

------------

An immediate (and theoretically expected) observation is that as the voltage is gradually increased from zero, nothing visible happens until a certain voltage is reached, at which it 'suddenly switches on', albeit with fairly low brightness. This 'switching point' was just under 10V for this segment+3LEDs chain.

I would expect a segment in the 3.5" display to be similar, albeit with a "switching voltage" of about 8V.

The Sparkfun display data sheet shows 6 LEDs in series for each segment. (The information provided is a little confusing!), with a forward voltage of 11.6V to 12.4V at 20mA.

Specifying a 12V supply, might result in a rather small current if the actual supply voltage is on the low side, and the display was near the 12.4V maximum, resulting in a disappointing result. This is why I do not like the board, as supplied to customers expecting a 'wire and play' solution.

-----------------------------

In a little more detail, you may like to consider this 'thought experiment'.

With a forward biased diode, including an LED, if the voltage across the diode is sufficient for it to appreciably conduct, then that voltage will be roughly constant for considerable increases in current. This means that in the usual resistor + LED in series arrangement, if the supply voltage increases by say 1V, then nearly all of that increase will appear across the resistor. Thus, it is possible to use the V=IR relationship to estimate the current increase.

With a series resistor of 500 Ohm, a 2mA (increase) in current results in a 1V drop (increase) across the resistor. This means a 1V supply increase will be "absorbed" by the resistor, providing the current increases by 2mA. For an LED rated at (say) 30mA maximum, a change of 2mA is quite small and usually acceptable.

However, if the resistor is 15 Ohm, a supply increase of 1V corresponds to about 67mA. A 67mA increase for an LED rated at 30mA maximum, suggests magic smoke is a near future possibility!

Of course, this calculation is oversimplified, but it illustrates the trend.

How this ties in with Sparkfun's claims about the voltage supply being ok with 11V to 14V, I don't know.

----------------------------

I have only ever calculated resistor values by hand, using the spec sheet's forward voltage drop, expected voltage, desired current and Ohm's Law.

R = (V - Vled) / I e.g. R = (5 - 2) / 0.01 = 300 Ohms for red LED, 5V supply, 10 mA current

Usually, it has been for a discrete LED, which has space around it to lose a little excess heat, so I would expect them to be pretty resilient. Also, they don't usually need to be run at full current. Normally, the resistor value is 100 Ohm or more, which I have few qualms about. If I was designing a product, I would probably look more closely if the resistor value went substantially below 100 Ohms.

---------------------------

For LED currents of say up to 50 mA, the simple resistor solution is usually fine.

Obviously, for the high powered LEDs, such as maybe a headlamp for a car, a switched regulator's efficiency would be much more attractive than a huge power resistor.

However, it should not be "constant voltage" but "constant current". Whilst a 'controllable' constant voltage supply provides some 'adjustability', this is only for someone who likes continually adjusting things ... it is not a robust solution.

-----------------------

The data sheet for the 3.5 inch that the OP posted, is indeed minimal, confusing and contradictory. In part, this is because it will usually be used as a 'group', e.g. a 4-digit voltmeter. Only requiring one digit is quite unusual.

When used as a group, then rather than having a driver, resistor, etc. for each segment, it is common to start paralleling the connections, so that if there are 4 digits, then at any one moment, only one has powered by the anode, but all 4 digits have the same cathode drives. Obviously, only the powered digit is illuminated. The electronics then just time multiplexes across all of the digits. Under these conditions, the current through a segment can be higher than the continuous value, since it is only powered for a quarter of the time.

So per segment, 50mA maximum continuous, and 80mA maximum if it only powered for a fraction of the time. (I seem to recall, they also specify an average power dissipation limit that should not be exceeded.)

The 20mA figure is a nominal value that is used for many of the parameters, such as light output, etc. and seems to be a 'standard test' condition. Perhaps it is a 'typical' value they expect most customers to use in their products?

------------------------------------

I agree that Louis' solution also appears to be valid, and also uses less GPIO pins. I wrote two consecutive messages, the first a 'principles' discussion, the second reporting on a trial I did, based on an idea I floated in the first. In the first message I wrote:

Louis's BCD to 7 segment drivers simplify some decisions, and only use 4 pins to connect.

---------

An alternate approach might use 7 microcontroller outputs, instead of 4, one for each segment, then something like a ULN2003 as the driver chip....

I have also previously acknowledged Louis' contribution, closer to when he originally made it.

Technically, both have pros and cons, but both will probably do the job.

I wanted to check a few things experimentally for myself, without waiting or paying for deliveries, so I only used what I already had, which included the driver chip described, simply because it is so common and well-known, it comes in the 'boxed bargain' sets of 'handy' chips that AliExpress, Amazon, etc. sell.

As for price, it is basically down to vendor's costs of handling & delivery. The actual chip is about 50 pence (US$0.60) each in UK (including tax & delivery) from Amazon, but from that source, they only come in packs of 10.

eBay has a single offering of 50 pence each for 7446 chips, in a pack of 5, but I didn't spot any other alternatives that were 'competitive' (I failed in DigiKey and over £13 delivered from only 1 source in AliExpress, but sourcing parts is not my speciality or interest.). I feared the 7446 may shortly become more difficult to source, but they may not an issue.

----------------------

Best wishes, Dave

@davee Sorry Dave, I am busy with something else as I thought this Topic was Solved. You seem to be still talking about the 6.5" LED and the Large Digit Driver. The OP NEVER considered the 6.5" and thanks to Louis (@inst-tech) the OP has a workable solution.

I apologize for only skimming your usual long sermon (something to do with being a Brit?) so if I got the gist of it wrong just ignore me as usual.

Like I said, I am under the impression this is a solved case by using the solution Louis presented. I am sure yours also works but with more parts.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi @billinfl,

Great to hear your story. I can't predict how it will end, but let's see if we help to add a little more to Chapter 1!

One question I should like to clarify...and sorry if it seems "over the top", but all too often, someone asks for some advice, but only states 10% of what they really intend. Consequently, the answer is 100% inappropriate.

--------------------------

The 'Entire' project, as I understand it, consists of 'free-standing' unit That is something with no other connections or dependencies, including no wireless communications, etc., or other controls, displays, etc.:

- Load cell with supporting mechanics, and pan to hold up to 9 widgets

- HX711

- microcontroller

- 1 large digit display, with electronics to enable microcontroller to command a digit chosen from 0..9, dependent upon weight of widgets in the pan

- mains power supply for all of the above

Is this an accurate picture?

-------

As a supplementary, but much less important question for now, if this project eventually works out ok, do you think it is likely you will do other projects involving microcontrollers, etc.?

Thanks, Dave

Hi Ron @zander,

No problem.

The 6.5" display is only relevant, because it is the only display the SparkFun board is capable of driving directly, without modifications.

I think Louis made a valuable contribution and step in the right general direction, but the OP is still a long way from a completed solution. But, as with every non-trivial project, one step at a time.

Best wishes and take my friend, Dave

@davee Dave, So glad to read your response, especially the first two sentences, since I was apprehensive about posting too much gibberish about my personal history and technical limitations and other unnecessary details. I figured that none of that info would ever need to come up, because my (wrong) assumption was that just a single post would instantly have several easy answers to choose from, and I'd have this gizmo all soldered and plugged together in no time. Fact is, this is taking up more of your folks time than I would have hoped. Ah, the drawbacks of being an optimist! As far as your "over the top" concern, absolutely no worries there. I should have given more details in my first post, so as to better facilitate helping me. As it stands now, your "entire project" list is 98 percent correct. I just wasn't sure if the following mattered or not, but here goes:

There are two identical (fully independent setups needed, which I now realize is good to know since they can share the same power supply(?)

The power supply,(12 volts, ? amps.... whatever is decided), can be any dimension long and wide, but would be helpful if no more than 2 inches thick. Concrete wall in mounting location making things tricky, (but surmountable with a good hammer drill of course!)

The LED size I chose is a 3" high digit. It just works best for the distance to the viewer. I think I saw 3.5" mentioned. I checked the data sheet, and it looks like they at least got that right!

The 9 objects are 6 ounces each.

And, yes, whether this project works out or not, I am now aware of how neat these things are, and I can easily see myself thinking up other uses, as I have aways been a tinkerer, and just love it when people say "that is really a cool thing you thought of and built! Did you come up with that idea?" Well, this is one of those.....perhaps my best one yet! I'm happy to share more details about exactly what led up to me undertaking this project, and why I think it's cool, but for now I refer you back to my first sentence. Thanks.

Hi @billinfl,

Thanks for your reply, which was once again useful and informative.

Never worry about giving too much detail. In general, very few people give 'too much', and nearly all 'too little'. When attempting to answer a query, it is much harder if you only know 'half the story', because you have to guess what is required, and in my case, too often the guess is inaccurate, so I answer the wrong question, wasting my time and the recipient's time.

I am having a think about the next best move, but for now, I have a couple of extra thoughts to add to my last message:

- Building two 'copies' of the unit.

- This affects you and your wallet mainly. One thing you may have already noted is that building electronics often means buying lots of 'little bits', like resistors, switches, capacitors, chips, and even small PCB based modules. Many of these are intrinsically cheap, but handling and delivery can make them expensive and time-consuming to procure, when you need quite a few different parts. You may have local suppliers, but for me (in the UK), it seems to be mainly down to a choice of three general groups: AliExpress & Banggood direct from China; Amazon & Ebay, who tend to offer similar parts to AliExpress, at a higher price but quicker delivery; and the 'professional' distributors like Farnell, DigiKey, etc. If I was considering a commercial/professional product then only the last group would generally be good enough, but for a home/fun project, spending my own money, the first group seems more appropriate, with occasional exceptions. However, that does mean 'juggling' order quantities, etc. as delivery cost and time can easily begin to dominate the rate of progress. I suggest you should also be prepared for such decisions. I am not recommending any of the choices, merely ensuring you understand the options, and choose wisely and responsibly. For example, if you need two of something, assuming everything goes to plan, do you just buy two, or do you buy (say) 3 or 5 or..., allowing for bad luck, future needs, etc.? Also, for your present project, the 'urgency' of procuring parts may affect the choice.

- For one 'component' in particular, namely the microcontroller board, it also has an effect. The UNO R4 WiFi you already bought, I guess, was a higher price than the lowest cost boards around, though hopefully not too painful. For two 'copies', you will clearly need at least two, suggesting a second one will need to be acquired at some point. Personally, I suggest you consider using a simpler 'dev' board style board, that is "mainly" just the processor, and a USB socket provision to connect to your computer for programming, etc. for this project, and reserve your UNO for some future experiments. I'll have a look around for suggestions, but I think the main 'essential' is at least 9 free GPIO pins, which shouldn't be too hard. To work with Louis' suggestion of 7446 chip, it will be easier if it's a 5V processor; for the ULN2003 I tested, 3.3V or 5V is ok.

- Wiring length sanity check.

- Most of the 'pin' connections to the electronic boards 'assume' the wire lengths will be short. That is in a commercial "widget weighing unit", everything from the weighing pan with load cell, to the display would probably be in the same unit. But, as you are building the 'system', it is conceivable that the weighing pan and display are 15 feet/5m apart, for some reason I didn't expect. Can I assume this is not the case, and the furthest separation will be less than (say) 3 feet/1m ? (It is not an insurmountable problem, but a bit more care would be appropriate.)

I hope these points are clear and helpful. If they provoke any thoughts or questions, please feel free to share them.

Best wishes, Dave

Dave, I see what you mean, and I will try and give as much information as I can from here on in. I also am familiar with the difference between the three tiers of suppliers you described. I have had limited experience over many years with all three as far as purchasing electronic components is concerned. I agree that there are cost, time, quality and customer service decisions to be made, and I'm usually having to guess at them. The guesses are sometimes right, and sometimes not. Just look at the example of the 3 inch displays I bought. First, they arrived with no data sheet. This led to me having to spend time beating the bushes to locate one online. No big deal, and plus, I've got time on my hands to fritter away on such things. Once I had the data sheet, I learned from folks here that several items were either misleading, omitted, or just plain wrong. The pinouts were wrong for sure, and it took me quite a while to figure those out. That was another time waste, but, more importantly, the poor documentation then led to others here having to spend their time deciphering what was going on. This bugs me because it made the people here just trying to help me having to take more of their time. But, on the other hand, Amazon charged me almost nothing for the displays, and they were on my porch the next morning. So you're right, it does get tricky.

As far as my board choice, I described why I bought the R-4 in my other post, and by the way, I've already bought two of them (needing 2 identical setups) because I had high hopes that those would do the job fine. I saw the cheaper ones, but 25.00 each didn't set off any alarm bells. Also, if you or someone else here suggests a better way to go for this project, I'm happy to purchase other boards, and use these UNO's for future projects.

Interesting that you would mention the wiring lengths! While waiting for a final "best way" to go with the led display driver issue, I thought the same thing you did about wire runs, so I did a mock up of the connections from the load cell amplifier to the uno. To be clear, that is the longest run for sure, since the runs from the power supply to the uno as well as from the uno to the wall display(s), are just a couple feet. The result was good, since the weight readings were exactly the same whether using one foot or 25 feet.

Lastly, your thoughts are always "clear and helpful", and I appreciate it. Bill.

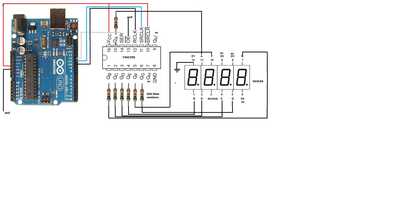

@davee, @billinfl , Hi Dave, and billinfl!... I've been following the @billinfl post, and I think I have another solution to the op's problem of getting parts and using the least amount of MCU pins. I built a counter 0-9 using a 74HC595 shift -register.

This should work as those parts are readily available, and cheap!...lol

The code is below so he can play with it and see how it works.

Hope this is helpful as I enjoyed working on it..lol

Regards, LouisR

/*

74HC595 Shift Register with 7-segment LED display

74hc595-7segdisplay.ino

Count in hex from 0-F and display on 7-segment Common Cathode LED display

DroneBot Workshop 2020

https://dronebotworkshop.com

*/

// Define Connections to 74HC595

// OE' pin 13 to gnd

// RCLK pin 12 to Uno pin 10

// SRCLR' pin 10 to Uno 5v Vcc

// SRCLK pin 11 to Uno pin 11

// SER pin 14 to Uno pin 12

// RCLK pin 12

const int latchPin = 10;

// SRCLK pin 11

const int clockPin = 11;

// SER pin 14

const int dataPin = 12;

// Patterns for characters 0,1,2,3,4,5,6,7,8,9

int datArray[16] = {B00111111, B00000110, B01011011, B01001111, B01100110, B01101101, B01111101, B00000111, B01111111, B01100111}; //, B11101110, B00111110, B10011100, B01111010, B10011110, B10001110};

void setup ()

{

// Setup pins as Outputs

pinMode(latchPin, OUTPUT);

pinMode(clockPin, OUTPUT);

pinMode(dataPin, OUTPUT);

Serial.begin(9600);

}

void loop()

{

// Count from 0 to 15

for (int num = 0; num < 10; num++)

{

Serial.println(num);

// ST_CP LOW to keep LEDs from changing while reading serial data

digitalWrite(latchPin, LOW);

// Shift out the bits

shiftOut(dataPin, clockPin, MSBFIRST, datArray[num]);

Serial.println(datArray[num],BIN);

// ST_CP HIGH change LEDs

digitalWrite(latchPin, HIGH);

delay(5000);

}

}

LouisR

Hi Louis @inst-tech,

Thanks for your clever solution, but unfortunately as it stands, it is not suitable for Bill @billinfl, because each segment of the 1-digit 7-segment LED display has 4 LEDs in series, suggesting a supply voltage of over 9V, and probably conveniently 12-15V, to provide a reasonable amount of 'constant current' capability from the series resistor. The 74HC595 appears to be limited to 6V.

I noticed, but have no experience of, at least one device in AliExpress and elsewhere ... the DM13A, that would probably be adaptable to your approach. It includes a form of current regulation, meaning only one resistor is included. However, the data sheet is a bit more complicated, so without trying it, I am reluctant to recommend it as a first project. (Also, I think, there are other chips with similar design intentions, but I know even less about them.)

Alternately, a 7-bit driver chip, like the ULN2003 could be used to boost the voltage capability, at the output of the 74HC595. (I am in the middle of writing a note, that includes the ULN2003.)

Best wishes, Dave

@davee , Yep..your correct..The fact that he op is using a common anode type display makes it a little harder to expedite parts to make his project workable...but I did find a suitable part .. the SN74LS47, is a BCD to DEC decoder display driver for common Anodes.. Data sheet says it 24 mA sink current, open collector, and 15 volts! this should work for the op..

here's a link to the data sheet.. https://www.ti.com/lit/ds/symlink/sn74ls47.pdf

It's on Amazon ( US) for about $8.59 for a pack of 10, that's about $0.85 each..pretty cheap...lol Any way, I don't have common anode displays to work with..so I won't be able to test it to see if it works for the op..I don't see any reason why it shouldn't, but it's not the first time I've been wrong..hehehe

I hope to see the op making progress on this project..

Thanks for the update. kind regards,

LouisR

LouisR

Hi Louis @inst-tech,

Thanks for the update. I agree, a glance at the data sheet suggests the SN74LS47 should work, providing the current limits (24mA) are above the current needed for sufficient brightness.

Bill @billinfl 's initial experiments suggested that only a modest current was required, so that looks hopeful.

Best wishes, Dave