@iwannastout I had equalizer bars on our first RV, just a little 21 ft bumper pull. It turned out my F150 didn't really need them so I stopped using them after a little while. RV salesman are shall we say a step down from used car salesmen.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

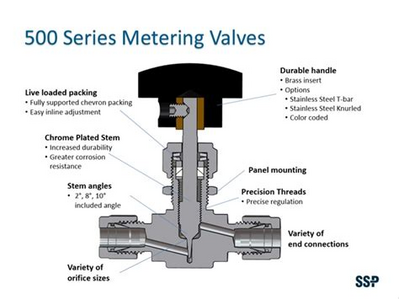

@iwannastout Sounds good! The only other thing you may need is a metering valve, also known as a needle valve in the exhaust side of the solenoid valve to control the bleed off.. it really depends on how large to solenoid port is.. If your looking into a software solution for the phone app. lake a look at this link: https://ai2.appinventor.mit.edu/#5488706868609024

I built an app for my robot tank using the MIT App inventor software, and am using WiFi..works very well..

Here a photo of a typical metering valve.

Regards,

LouisR

LouisR

@iwannastout Sounds good! The only other thing you may need is a metering valve, also known as a needle valve in the exhaust side of the solenoid valve to control the bleed off.. it really depends on how large to solenoid port is.. If your looking into a software solution for the phone app. lake a look at this link: https://ai2.appinventor.mit.edu/#5488706868609024

I built an app for my robot tank using the MIT App inventor software, and am using WiFi..works very well..

Regards,

LouisR

I really don't know yet if I need a metering valve. I was thinking I would send a short pulse to the solenoid, say start with 500ms, and see how that affects the system pressure. Since I am dealing with pressures in the 5-35PSI range, it's not like it is opening a valve with 300PSI behind it. By pulsing the valve it will probably decrease the life, but I don't suspect that I need it to pulse thousands and thousands of times over its lifetime. If it fails after a couple of years, I probably won't care, because it's likely it will be replaced by a full-sized truck by then.

Oh and thanks for the link to the MIT App inventor stuff, I'll have to check that out.

-Mike

@iwannastout , Hi Mike.. your very welcome!...Indeed, you can pulse it.. and it won't matter how many times you do, as you said, life expectancy is only a few years anyway!.. The scheme I came up with was an automatic re-pressurization and pressure relief where as the pressure sensor is monitoring and if the pressure goes up beyond the user defined set point, it opens the valve to exhaust..likewise, if the pressure goes below the set point, it starts the air pump.

This scheme requires a dead band of at least a psi or two to keep the pump from cycling on/off to quickly. So say your set point is 30 psig- and the pressure drops to 28, the dead band defined in the program is +/- 2 psig, so the pump would start and shut off when the pressure equals the set point of 30. Dead band is the value of psig when you want the pump to start or stop above or below the set point. this keeps the pump from cycling when the pressure varies a little from set point do to temperature or atmospheric (barametric) conditions like you may encounter in the mountains or desert at night. The Iphone used as a GUI will be handy as you need no wiring to the controls, just a blue tooth connection.

Good luck with your project... I think you have it all under control now...

Regards,

LouisR

LouisR

Okay, I have all the parts at home now to build out the hardware portion of my project, but I also have a clunking noise coming from the rear of my SUV that I feel needs attention soon. I am at 109k miles and it would not surprise me if something is worn out and/or needs replacing. I have some parts on order that should come in this week, and weather permitting, I plan to replace soon. I live in Michigan, so it's not always feasible to replace car parts in the middle of winter, even in a garage (just too darn cold and miserable). But I hope to tackle this work sooner than the air-suspension project. And while I am working on the rear of my vehicle, I should be able to get a good look at where to route the "T" and additional air line for the compressor/solenoid-valve. Maybe even get that part done at the same time. Then it will be time to focus on the software and app portion of my project.

@iwannastout I can appreciate not fixing cars in a Michigan winter. I grew up in the metro Detroit area and back in 75 I have to replace a seal in my transmission in the dead of winter. We had no garage, so I was outside working. That was very painful. It was also the only time I ran my mustang with the headers off to see how loud it was.

@iwannastout I just noticed your camper dry weight is only 4550. My 5th wheel is 16,000, before that my bumper pull was 8,000. With a trailer that light, you should not need any help in the sag department, my 8,000 used an equalizer hitch and when properly adjusted brought the front and back of the tow vehicle back to where it started minus maybe a 1/2" both ends. Are you sure you don't have something else wrong causing excessive sag, maybe that noise you are hearing is a clue? Good luck and tow safe.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@iwannastout I just noticed your camper dry weight is only 4550. My 5th wheel is 16,000, before that my bumper pull was 8,000. With a trailer that light, you should not need any help in the sag department, my 8,000 used an equalizer hitch and when properly adjusted brought the front and back of the tow vehicle back to where it started minus maybe a 1/2" both ends. Are you sure you don't have something else wrong causing excessive sag, maybe that noise you are hearing is a clue? Good luck and tow safe.

I don't have any excessive sag, never really had any since using this setup (weight distribution hitch and my full-frame SUV). I guess it's more of a personal preference, I like the feel of the stiffer suspension when towing my RV. But something is making a noise in the back that wasn't there about 6 months ago. So I'm going to replace the rear sway bar links, rear upper & lower control arms, and the rear sway bar bushings. Hoping that will take care of the noise. Then I can continue with the air-bag system. I guess this is one of the drawbacks of owning an older vehicle. 🤔

@iwannastout Ok, understood.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.