If this is a "Science Faire" type bot... it might spend most of its life just standing still and waving every so often. If the all other drivers are disabled... it might run continuously over a weekend while he waves to the audience, talks, blinks lights.

@inq I do have a Robby the Robot toy that walks, says things and lights up. (small scale version)

The ultimate goal for Robot 42 is to install AI. My rough idea at the moment is to use a raspberry pi, memory chip etc. and yes even give him a voice using a speaker hooked to the pi.

I am right now just out of

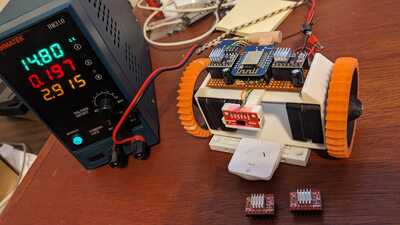

Phase I - building a body, and roughing in motors/gears

, and starting

Phase II - basic electronics - battery, drivers, lizard brain (Ardunio Mega R3), programing, adding sensors. simple remote control, etc...

Things to come...

Phase III

The Raspberry pi/ AI (If and this is a big IF I might be able to use GT Chat by plugging in the basics, and getting it to write the AI software - lol)

Hi @inq & Ron @zander & @greendragon,

Thanks, inq, for your input. In terms of rationale, I agree with you. Our previous discussions have been in the foreground of my thoughts throughout the trials and tribulations of this entire thread. That is, because you measured, and I estimated, the power supply current input is typically much lower than the motor coil current, the ratio being related to how much higher the power supply voltage is, compared to the nominal motor voltage of maybe 3V. Of course, the nominal motor voltage depends upon the motor type.

------------

As I mentioned before, I think 12V would be the minimum voltage to even consider, but higher will probably be more flexible, given appropriate driver electronics. I note you (Inq) discusses 18V, by which I assume you expect 6 Li-ions in series. I note the little Ender-3 printers now use 24V for their modest sized motors, albeit they must also accommodate bed heaters, etc., which may be tricky with only 12 V, so I am not sure which requirement persuaded them to use 24V. (I have a suspicion their early machines were 12V.)

--------------------

I also noted the design parts list does not currently include any 'specialised' stepper motor chips, with built-in current control ... just H-bridges. In principle, this should not matter, as the final motor drive must be similar, but it puts more emphasis on the software, which I guess will be Arduino or similar. How this manages the PWM drive for a near constant current drive, I don't know. In principle, with current measurement for each motor, software routines could emulate the 'specialised' chips, but whether any libraries are available, and whether the common, lower performance Arduino chips have the horsepower to support the functionality required, I don't know.

...

I realise Adafruit are showing a demo

suggesting a 12V supply, and I haven't spotted any current measurement.

Their mechanical 'load' is only a piece of sticky tape attached to the spindle to show it move. I am suspicious of what that is doing .. maybe just sending a short step pulse, and leaving the motor unpowered between steps? I may be missing the obvious, in which case I apologise in advance, but this doesn't "feel" right for 'serious' applications. I fear this part of the design needs a rethink.

It is much too late for me to look into this now ... I invite contributions from others .. and, depending on the comments, I may add a little more another day.

-----

I also just looked at the data sheet for the motor driver chips TB6612 .. https://toshiba.semicon-storage.com/info/TB6612FNG_datasheet_en_20141001.pdf?did=10660&prodName=TB6612FNG

It has a maximum voltage of 15V. This will not work well at 18V+ battery output!

------------------------------------------------------------------------

This makes the whole thing tricky to estimate the current demand, with dangers of being either too low, in which case it may not move properly or will flatten the battery in a very short time; or too high, making the battery extortionately expensive, and awkward to physically accommodate in the robot. Either way, with scanty knowledge of overall design, usage, etc., estimating the Goldilocks' solution seemed as tricky as using thermodynamics to explain why Baby Bear's smallest bowl cooled less quickly than the Mother's middle-sized bowl.

----

In addition, as you (Inq) surmise, it also depends on what the unit is expected to do, from a simple occasional royal hand wave to an amazing continuous display, given the number of motors.

I notice the constructor. greendragon is now talking about trying to add AI, etc., which might mean a single 'AI edge' chip type board, that is dormant most of the time, or a substantial number cruncher, running for long periods of time, which together with the motors, could require a larger energy store.

--------------

Personally, I still think some real measurements are required, assuming the constructor needs to buy batteries, rather than recycle from the junk box. Obviously, if you have spare batteries in the junk box, that is a slightly different scenario.

I also think it is wise to initially commission complex units, whilst iterating the design, with (bench) power supplies with current limits, etc., rather than batteries that can source appreciable current when short-circuited. Of course, fuses, trips, etc. can provide some protection, but a simple mistake or slip of a screwdriver may do more damage than a modest bench supply costs, and the safety side speaks for itself.

----

Best wishes, to all, especially the plucky constructor, greendragon. I wish you all well with your projects. Please do not think I am saying that your aspirations are impossible .. just that they may benefit from a little more patience and refining, so just hang on for the ride.

Dave

Best wishes, to all, especially the plucky constructor, greendragon. I wish you all well with your projects. Please do not think I am saying that your aspirations are impossible .. just that they may benefit from a little more patience and refining, so just hang on for the ride.

@DaveE I understand your concern, and if a had a workshop like dronebot then yes I would do a lot more things, and have better Data to work with, but all I have is a shoe box full of tools, and a folding table. So I have to take some chances, and try some things out. The simple fact is that almost nobody builds a robot with this many stepper motors in the hobby realm. So I'm a trend setter (lol). I also know that you would like me to explane exactly how, and what everything on my robot does in detail, and the simple fact is I am afraid of giving away my design secrets. I know the concept of keeping your designs secret may shock some users, but I was brought up in a different time. I have been mulling over in my brain about making Robot 42 a open source project, but at the moment I just can't bring myself to do it. - Bill

@greendragon FYI @davee FYI @inq The available space is only about 3" wide, so that fake Makita battery is a non-starter. I discovered the 32700 LiFePO4 cell. First, it is the safest chemistry, which is important to the OP. A 4S2P yields 12.8V at 20A peak with a capacity of 12Ah. That will provide lots of power. and at 64mm/2.52" wide, 70nn/2.76" high (plus a bit for connectors) and 128mm/5.04" deep will leave.

His space for the batteries, Arduino mega, several sensors etc is

3"W x 5.25"D x 10.25"H <--- available space

2.52"W x 5.04"D x 3"H <--- 4S2P 32700 battery pack

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

As I mentioned before, I think 12V would be the minimum voltage to even consider, but higher will probably be more flexible, given appropriate driver electronics.

I totally agree! I played around a lot with these steppers. Switching from A4988 to DRV8825 opened up even more potential. I will always recommend these at the bottom end. I still have a set of the TMC2209 to really dig into some day. But, I digress. Using a bench power supply, I was able to vary the voltage and have enough current to let it "take what it could handle". Because the drivers sense and limit the current going to the stepper, there is really no reason to limit the upper end voltage based on the steppers. It's all about what the driver's upper voltage limit is. Anything below say 10V and the steppers will miss steps with very little resistance. As voltage goes up, they "snap to" far better, accelerate far better and resist skipping step under load far better. The DRV8825 can handle more voltage than my bench can supply (32V) but at that, stepper motors are extremely powerful.

I note you (Inq) discusses 18V, by which I assume you expect 6 Li-ions in series.

LiFePo4 nominal voltage is 3.2V. I was assuming the Makita 18V brick is using hi-rate discharge LiIon with the nominal, nearly flat region of the discharge curve is 3.7V... and that those type of batteries tend to be around 2000 mAh in the 18650 size. Thus, I'm guessing the Makita 6Ahr, 18V brick to be a 5S3P.

Ender-3 printers now use 24V for their modest sized motors, albeit they must also accommodate bed heaters, etc., which may be tricky with only 12 V

Right on! Most bottom end ones started out at 12V, but most are at least 24V now. The biggest reason state is the bed heater, but they were able to get more out of, or use smaller steppers with the higher 24V. At economies of scale, I bet it's actually cheaper to produce 24V systems.

I also noted the design parts list does not currently include any 'specialised' stepper motor chips, with built-in current control ... just H-bridges.

With the commodity pricing of 3D printer stepper drivers, I wouldn't even look at L298H type drivers when you can get a far smaller, higher capacity, with current regulated, short-protection driver for less than $2US a piece. I'd recommend the DRV8825 for this project or any stepper up to about 2A per coil... which covers most Nema-17s. Software drivers like AccelStepper make it pretty easy to synchronize as necessary.

I guess will be Arduino or similar.

In the post above, @greendragon mentions Raspberry Pi. I'd be real curious how well that works. I've always been told the preemptive multi-tasking nature of Linux is not a good fit for real-time systems. I've always planned on using ESP8266/ESP32 for driving steppers/servos/etc and have a RasPi as a brain/conductor that would handle the AI decisions/talking/interaction with the human.

I notice the constructor. greendragon is now talking about trying to add AI, etc., which might mean a single 'AI edge' chip type board, that is dormant most of the time, or a substantial number cruncher, running for long periods of time, which together with the motors, could require a larger energy store.

I'm still running simple movement AI on an ESP8266, but thought about my future progressing moving up to RasPi and then to the Nvidia Jetson. I also read about a new Orange Pi SBC out with a built-in AI processor that has 16GB or ram!!! Ought to be a beast - https://liliputing.com/orange-pi-aipro-single-board-computer-features-a-hauwei-ascend-ai-chip-and-up-to-16gb-ram/

But there is also the ability of just using a RasPi with Internet connection to interact with ChatGPT, et al to supply the AI functionality and just have text-to-voice or text to action processing on the the Pi.

I also think it is wise to initially commission complex units, whilst iterating the design, with (bench) power supplies with current limits, etc., rather than batteries

I completely agree here also. A bench power supply can let him test at different voltages and see the results and also allow him to see the energy demands while on a tether and calculate the desired battery capacity needed... economizing or optimizing... dealer's choice. It has been one of my best tool buys!

Best wishes, to all, especially the plucky constructor, greendragon.

Agreed... I'll enjoy watching the build-thread. Good luck @greendragon!

VBR,

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

I'd really suggest you try out a few breadboard tests before committing to metal... My gut feeling 12V with those small steppers and such a large, heavy bot may have difficulty just starting to move. You'll definitely need to use micro-stepping on the drivers just to start it off and have to accelerate slowly.

My InqEgg bot is a featherweight, with slightly bigger steppers running on (4S1P) 14.8V. It can get up to about 4 mph at which point it starts missing steps and grinds to a halt.

My Inqster bot (still not tested) is expected to get well up into double digits mph, but uses the 84 oz-in Nema-17s and 22.2V (6S2P).

VBR,

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq I am not sure why you think that 18V battery that is too big physically to fit is a Makita, it is a knock off. Also, @greendragon has been very clear that he does not want LiIon or LiPo as they are the #1 and #2 most dangerous batteries. We each have our own level of risk aversion; we need to respect that.

FYI, many RVers put their LiFePO4 under their beds, that's how safe they are.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Hi Bill @greendragon,

@DaveE I understand your concern, and if a had a workshop like dronebot then yes I would do a lot more things, and have better Data to work with, but all I have is a shoe box full of tools, and a folding table. So I have to take some chances, and try some things out. The simple fact is that almost nobody builds a robot with this many stepper motors in the hobby realm. So I'm a trend setter (lol). I also know that you would like me to explane exactly how, and what everything on my robot does in detail, and the simple fact is I am afraid of giving away my design secrets. I know the concept of keeping your designs secret may shock some users, but I was brought up in a different time. I have been mulling over in my brain about making Robot 42 a open source project, but at the moment I just can't bring myself to do it. - Bill

I suspect few of us have a workshop like Bill (@dronebot-workshop)'s!

However, regardless of whether we are in the 'kitchen table' league or the 'NASA' league, we all have to take chances and try things out, if we wish to discover or achieve something new.

-----

More importantly, I am not clear if you do 'Understand my concern'.

Personally, I am not trying to get you to share any 'trade secrets' or open source anything. Of course, had it not been for the general 'open source' change, a large proportion of what is discussed on his forum would have been confined to research and development labs with price tags that would have eliminated most of us from being involved, and it is interesting to see what and how can be accomplished in sharing environment. We can all learn from people like @inq who has very kindly offered a lot of experience, etc. ,as well others like Bill who freely offer insights and tutorials that would otherwise not exist.

However, my reason for any questions regarding your project have been solely to determine answers to, or related to your question, including the feasibility of your motor controller/strategy, which I have some doubts about, based on the 'bill of materials' in your first post, albeit those doubts are based more on my imagination of what you are doing than the data you have provided. (If this strategy changes, so might the power source requirements.)

As a lifelong scientist/engineer, I cannot answer any question properly without understanding the circumstances that affect the answer. Of course, anybody can suggest an 'answer' with little or no understanding of the complete problem. Whether that answer bears any connection to reality is a different matter. Repeating stock keyword answers is commonplace as it is trivially easy ... getting an accurate answer can be a lot harder.

--------

As to the extent you are a 'trend setter', or whether you have 'trade secrets' to give away, I don't know. I suspect, that most or all of the more informed contributors to this forum have a few details they cannot share from their past, and maybe even their present, which is fine providing it does not involve their forum discussions. However, if you are asking for others to give their time and experience away free to help you design a new widget, perhaps with the hope of making a profit, without even being willing to share sufficient details of what and how you are presently trying to accomplish, to enable them to answer your question in a competent fashion, then I begin to wonder whether I am doing the right thing, by trying to assist. If this is the situation, then not only am I wasting my time trying to answer what is probably the wrong question, but you are wasting your time, because the answer is likely to be irrelevant or misleading.

-----------------

I hope my fears are wrong, and that this is just an unfortunate misinterpretation on my part ... for which I apologise in advance if it has happened. However, I feel you should clarify your position, both to yourself and to the forum.

I wish you all the best, Dave

@davee @greendragon I think you are misunderstanding. I do not think he has any 'trade secrets', he is strictly talking about his robot and I don't see how that competes with Atlas now or ever.

Since he said he does not want to explane anything, it may be that none of us can help him more. Once he said the battery pack plus Mega plus sensor boards etc all have to fit into a volume of

3"W x 5.25"D x 10.25"H he severely limited his options.

Until he has a number for average current used over a sufficient period of average activity we are unable to do the math, but my hunch is the battery pack I told him about with 12.8VDC 20A peak and 12,000mAh capacity will do the job. IF he needs more voltage for some of the steppers, simply add more cells in series to provide what is best for the motors while using buck converters to tap off 12VDC or 5VDC etc. The number of batteries in series will of course be linited by the available space. I would start with how much space all the other equipment needs to see what is left over for the battery pack. He just needs to learn about how to make a battery out of raw cells (welder, nickel sheet, captan tape, thermal tape) and how to judge a good BMS vs a junk BMS. I told him about Will Prowse, the established expert in all things battery and solar.

I have led the horse to the water, but it is up to him to drink

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

More importantly, I am not clear if you do 'Understand my concern'.

Personally, I am not trying to get you to share any 'trade secrets'

...

However, my reason for any questions regarding your project have been solely to determine answers to, or related to your question, including the feasibility of your motor controller/strategy, which I have some doubts about, based on the 'bill of materials' in your first post

...

As a lifelong scientist/engineer, I cannot answer any question properly without understanding the circumstances that affect the answer. Of course, anybody can suggest an 'answer' with little or no understanding of the complete problem. Whether that answer bears any connection to reality is a different matter.

...

As to the extent you are a 'trend setter', or whether you have 'trade secrets'

EXACTLY. And exactly where I am also. You can get a kit for ~$50US to build a cardboard or plastic robot that uses AI, will avoid obstacles, will follow you around, talk to you. None of mine are capable of that yet. One should have end-goals. Maybe @greendragon does have a significant goal that is enough different/better/cheaper than what is currently available. I celebrate and encourage his desire to learn and innovate.

From the OP, I question that the mere Physics don't add up to a robot that can even start moving. Changing battery chemistries. Proposing a battery that won't fit his current design. Designing the bot in the image of a character first and expecting that to be a fixed requirement in the light of newer, learned requirements. Going from near zero to 42 without any intermediate trials. These things tells me a great deal about his current knowledge on the subjects involved. We all have to start somewhere and this forum is about learning and/or sharing what we have learned. And if we don't try things and fail sometimes, we're not learning anything anyway.

We here on the forum... are glad to help, but if one gives us invalid data through some misguided desire to protect IP, then the replies can only be counted on to lead one astray.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq I am not sure why you think that 18V battery that is too big physically to fit is a Makita, it is a knock off. Also, @greendragon has been very clear that he does not want LiIon or LiPo as they are the #1 and #2 most dangerous batteries. We each have our own level of risk aversion; we need to respect that.

FYI, many RVers put their LiFePO4 under their beds, that's how safe they are.

Apologies. I haven't read all the posts (in this thread). I've read your all's banter back and forth about batteries before and don't need to re-read your opinions. I've only read that at one time @greendragon proposed https://forum.dronebotworkshop.com/postid/44499/ . I assumed he'd done at least the physical size/weight evaluation. If he has since chosen LiFePO4, I had not read that. I do respect anyone's choices, once I know they've made them and I have no input to offer on battery chemistry safety.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq @greendragon Crawl before walk is always a good approach.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

@inq The reason you didn't read it is because it was a private message to me. The specific link is https://www.ebay.com/itm/266279786466

I just noticed a correction. Max continuous Discharging Current is 3C (18,000mA) and Max Pulse Discharging Current is (10C, 3S).

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Back to Subject of a Battery:

The following is the latest proposal on the table -

Using LiFePo4 3.2V 6000mAh Battery 32700 LFP Cells to Build a 4S2P 32700 battery pack

Here is the ink to the proposed Cells if you need more information about them.

https://www.ebay.com/itm/266279786466

If I understand correctly this will create a 12.8V at 12AH

It has been suggested that the battery should be more powerful due too unknown variables in load.

I can see this, and am a big believer in overbuilding if possible. It's not going to cost a ton of money to do this, and it would be easier to plan to do it before then after building the battery.

So how much more Voltage/AH would you suggest??

GreenDragon

@greendragon I think this is a logical place for me to withdraw. It is a simple matter to have a look at the videos/articles that Bill (dronebat-workshop) has produced to learn about ghow motor drivers are calculated and configured. Only you have the device and know about the specs, nobody else can realistically help you.

Good luck.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.