I actually enjoy working on them all in some sense. This past week I was repairing my tractor and it took me the whole week to do it. I enjoyed the work, but there goes an entire week too! I just finished the tractor today and it feels GREAT to have that tractor back running again.

Although I did do some work on my robot in the evenings.

So true. In fact, I actually currently have 6 robots that I'm working on. Although I really consider it to be a single robot project. Like you say, work you do on a robot tends to add more functionality. So all of these robot projects are ultimately contributing to a grand design. At least I hope so. ? That's the plan.

DroneBot Workshop Robotics Engineer

James

Today I did some work on two of my robots. I installed the motor encoders. These are a module marked FC-03. I put them on two robot cars I have. It was a major project for a couple reasons. First I had to de-solder the connection pins and move them to the other side of the board. In order to do this I actually had to cut the plastic header they are mounted on apart using a small razor saw and then move them individually. But it all went well. Then I had to drill a mounting hole in the plastic chassis. But now they are all mounted. I only took pictures of one of them but I did two today. I'm looking forward to working with being able to monitor the motors speed, acceleration, and distance traveled. So this will be quite the addition to the project.

Here's a photo of the finished hack:

Close up of the encoders.

I'm looking forward to using these encoders in the Arduino motor control program.

DroneBot Workshop Robotics Engineer

James

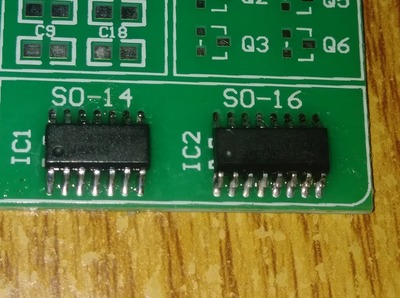

today i took a stab at SMD soldering. just got my practice board in the mail.

i have a BiaxiaSpherical Rotating 56 LED POV Soldering Welding Electronic Kit LJ that ive been wanting to play with but the SMD scared me

but i didnt want to mess it up at $35 USD

but i think i was stressing over nothing.

EDIT:

So-16 was my 1st try SO-14 was the 2nd

Nice job on the SMD soldering! Good luck with the Blue DIY BiaxiaSpherical Rotating 56 LED POV kit. You'll be an SMD pro after assembling that thing. ?

By the way, you should take a lot of photos when you assemble the thing and post them here as an article on your adventure into massive SMD soldering.

DroneBot Workshop Robotics Engineer

James

I was able to salvage the Power Supply from an old Franklin computer. It has four voltage outputs +/- 5V and +/- 12 volts. This will make a nice bench supply. There were also some nice hefty 12 volt stepper motors in the hard drives I salvaged along with 2 large 12 v PM motors.

The power supply complete with fan and runs very quietly.

And the stepper and PM motors.

DroneBot Workshop Robotics Engineer

James

I used to work for a sub contract manufacturer and wehad to test finished smt assemblies, with practise you can remove and replace many components using a standard weller iron and liuid flux, including ic's. get some scrap pcb's and practice removing and replacing components on them.

I am also a fan of the cheap 'practice welding kits' on the various Chinese web sites. You can often get a pack of 10 for $5 with free shipping. Every day when you first sit down in the shop put a kit together, test to make sure it works, and throw it away.

I was thinking of trying the hot air method of soldering. I actually have a nice hot air soldering gun. It has a small tip and isn't much larger than a soldering iron. But the guy in this video blasts his boards with a standard size heat gun. I would think he would blow the parts away. But surprisingly he does a nice job with it. And he just slaps the solder past on without worrying that it's bridging pads. It's amazing how well it works.

DroneBot Workshop Robotics Engineer

James

Here's a nice video using hot air SMD soldering.

DroneBot Workshop Robotics Engineer

James

yeah ive been using the solder paste and hot air. it works really well and its super easy i guess its just seemed hard in my head at first. all them little pins seem overwhelming. i got a knight rider scrolling led kit in the mail yesterday. going to play with that a bit later. i spent all day out on the Mississippi river yesterday so im sorta slow today.

and thanks for the videos.

I am also a fan of the cheap 'practice welding kits' on the various Chinese web sites. You can often get a pack of 10 for $5 with free shipping. Every day when you first sit down in the shop put a kit together, test to make sure it works, and throw it away.

yeah thats what i did. im really liking all the kits ive found so far they are fun quick projects

Thanks for posting James. Quite interesting. I have 3 identical boards, and the parts, waiting to be assembled off to the side of my bench that have been sitting there for at least a year now, so I think I might just use that method to finally finish them. I had previously done one of the original 4 boards by individually soldering all of the SMD parts one at a time. Man was that time consuming and very tiring.

SteveG

Thanks for posting James. Quite interesting. I have 3 identical boards, and the parts, waiting to be assembled off to the side of my bench that have been sitting there for at least a year now, so I think I might just use that method to finally finish them. I had previously done one of the original 4 boards by individually soldering all of the SMD parts one at a time. Man was that time consuming and very tiring.

dont worry about any solder bridges a little but of flux and and a soldering iron with clean it up if you use too much paste use some flux and a wick and it will clean up nicely

first time on a real PCB

I had to go over the SMD IC's a couple times. Getting the right amount of paste seems to be an art

Here's another video that goes into the technical details of how much heat to apply and for how long. He also offers some other tips for pre-soldering pads on the board before using the hot air technique.

It amazes me how well this system works. If you push the chip off the pads while the solder is molten it will re-center itself the moment you let go of it due to wicking actions. It's amazing that this system has such a natural ability to correct itself.

In any case, this video contains some interesting tips I thought. Like the use of a board pre-heater underneath the board. Is someone is planning on doing a lot of SMD work it would probably be beneficial to take the time to set up an SMD workstation that takes advantages of all the best tips. I've done absolutely zero SMD soldering up to this point, but I'm looking at starting using these breakout boards. Especially for possible use for buffer chips at each end of an I2C line.

Here's the boards I'm looking at:

These are simple break-out boards for SOP-8 chips to terminals. The SMD chips are a lot cheaper than DIP chips, even including these breakout boards. Because with the DIP chips you'd still need a board or socket for the chip. So this appears to be the most financially efficient way to use these inexpensive chips. But they will all need to be soldered to these little breakout boards. Sounds like a good first SMD soldering project for me to learn on.

DroneBot Workshop Robotics Engineer

James