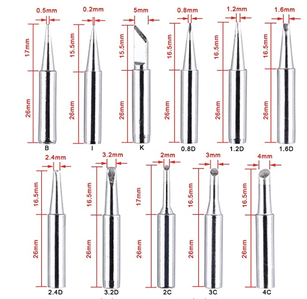

What is recommended for soldering iron tips. I have a type that is about ID 4.2mm and OD 6.5mm. I think I need really tiny (0.2mm, 0.5mm) conical tips for most stuff. Any differences in materials? I saw one set with layers, copper, stainless, more vs straight copper.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@ronalex4203

That tip looks about right to start with.

Keep using it until you find that it's not suitable; determine what particular aspect about it is making it unsuitable; research and obtain a superior replacement; rinse and repeat as necessary 🙂

Anything seems possible when you don't know what you're talking about.

@will It looks like you and I are of the two schools of learning. You are more pragmatic and I am more theoretical. Kind of like each speaking a foreign language.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@ronalex4203

Absolutely !

If you were going to be working on something on which lives (human or animal) were hanging on a thread, then I'd say get the precise tools and supplies you need.

But hey, you're talking about reed switches, radar and PIR sensors to detect door opening and closing with possible use as intruder detection. What's the chances of failing using an inappropriate soldering tip ?

That said, the tip you display should be perfectly serviceable for years. You'll only need something different (at least smaller) if you need to work a lot of work on tiny SMD parts. And if that happens you'll need a whole different tool (rework) and solder (paste).

By the way, did I mention that I'm a Cheap Bastard ? 🙂

Anything seems possible when you don't know what you're talking about.

@will AH, got it. So I guess I will be buying ALL the beers!

I get you, but it's my learning style that has worked pretty well for me over the years (numerous awards, career success, own company etc) and I get pretty antsy if forced to learn some other way. On the other hand if I was building a team or better still a company you would be my first hire. I can value and respect other approaches, I just can't change.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@ronalex4203

There's no need to change, but you can feel free to stop worrying about small details, in electronics you'll find more than enough big details and gotchas to keep you occupied 🙂

I think I opined, in a previous thread, that you should avoid buying tools until you're forced to get them and spend the money on parts.

I'm too old and jaded to be useful in a work environment, besides I have the attention span of a weasel after a double hit of espresso !

Anything seems possible when you don't know what you're talking about.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@ronalex4203

Absolutely, it's enough.

I bought a similar set about 8 years ago and I'm still using the first (conical) tip I put on. I have a roll of 2mm resin core solder and when I turn the iron off I touch the tip to the end of that roll to get a nice, fresh, juicy blob of solder covering the tip.

Anything seems possible when you don't know what you're talking about.

Personally, I have found the straight conical tip the most challenging to find an appropriate use for.

As a general rule, each tip will have a distinct heated surface that is appropriate to use it for... and I just don't solder anything in an inverse barrel or inverse cone shape. The only time I think I use the conical tip is desoldering through-hole components off of donor boards.

The rest of them have purposes, but as per Murphy, you will never have the tip you want on the iron. Wide-flat irons are good for brush soldering ICs (with extensive use of flux), but for most of the detail work I've done... the small oval tips and small wedge tips are the most used. You want a surface where the entire active iron surface is in contact with whatever you are trying to heat for the best results.

I do highly recommend looking up iron tip tinning and trying a few of the tip-cleaning options.

EDIT: My habit of answering a thread and then reading the original question strikes again....

The material differences are basically endurance and effectiveness tradeoffs. Copper is better than iron/steel at soldering, but the solder is slowly dissolving the copper in the tip.

"A resistor makes a lightbulb and a capacitor makes an explosion when connected wrong"

"There are two types of electrical engineers, those intentionally making antennas and those accidentally doing so."

@jker Murphy was an optimist. Since I am just getting started with much of this I can't predict what tips are best so I bought a collection. I do have the usual suspects re tinning.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.