Hi

I am a retired electrical engineer. Worked mostly in instrumentation and control. Used to be "on the tools" but latter part of my career I drifted to the dark side - management.

I mostly worked on big things - Oilfields, trains, pipelines, materials handling etc. In the early years this involved real work with relays, computers (when they cost $M) PLC and other platforms. Worked on some fun moving machines - coal stacker / reclaimers weighing in at > 400 tons.

Used lots of languages for control and management automation. Was once fluent in RatFor under RSX11. You won't find much of that around these days.

To keep my hand in in later years I have done a fair bit of hobby work with Arduino and other platforms. Recently though I have trouble getting the caffeine levels high enough to progress these projects. Not even enough to do a water timer based on a nodemcu with Bluetooth control which I desperately need on my hobby farm. Need to be able to set up sequential timers. Not enough water to do do more than one at a time.

One of my favourites is a walking robot platform with 8 "legs" entirely novel from what I can work out. Look out Boston Dynamics! It is controlled by a uno with servo drivers to get the necessary 24 servo channels. Controlled by a 6 channel rc handset to a rc receiver. Built in a few hours with hand tools (no 3D printer in those days). I haven't had my prototype out for a walk for a while but I think it is still in serviceable condition.

It has lots of design space - geometry, number of legs, gait and there may be offshoots of a 3D actuator with injection moulded live hinges for who knows what applications.

I had a plan to develop it further with the help of a community but life has intervened and I see that I haven't done anything with it since 2015.

I am hoping that this community may be interested and I will be happy to share it.

Enough of the technical stuff. If you want to know a bit about me try theoneabout.substack.com. (Hope this does not break any of the forum rules?)

Patrick

PWD

Interesting past history--I'm also a retired electrical engineer with background similar to yours. Work was steel mills, blast furnaces, mine hoists, material handling and quite few things I can't remember. Also an interesting side track into electrostatic precipitators (dust collectors).

@patrickwd and @foxy,

This must be the Instrument/Electrical forum..LOL What a coincidence that we three are all from the same industrial back-ground! I'm a retired industrial Instr./Electrical tech. ( ie: Inst-Tech) With over 40 years of experience. I'm retired from the pulp and Paper industry after 28 years, but was in industrial construction for 12 years before, working in Oil & Gas refineries, petrol-chemical, power utilities, and Off-shore oil platforms.

Was a Weapons system tech in the Navy, (where I learned electronics) in ASW, D.A.S.H, and Asroc platforms.

I was the SME, at the plant where I worked for the previous 28 years, in Control Valve Asset management (CVAM) where I managed all the mills control valve issues from sizing/Selecting, repairs, and training.

Great to meet fellow alumni ..lol

Kind Regards,

LouisR

LouisR

While I wasn't an instrument tech for a pulp and paper giant, I was a computer/network SME from the HQ of a large company that had lots of pulp and paper mills, as well as other types of mills. If your company was the same then we may have been in the same mill at some point.

SteveG

I worked for International paper in N.W. Florida, who was previously Champion International ..

Was there for 28 years before retirement in 2014.

Kind regards

LlouisR

LouisR

PWD

@inst-tech 28 years sounds like forever. I worked mostly on big projects on contract and moved on as they finished. 3 years was about the longest.

Also what are you into now?

Thanks

Patrick

PWD

Indeed, It seemed like forever too!..lol

But that's all behind me now...As I'm into learning more about Iot and automation as it relates to consumer and hobby projects. First thing I needed to do was learn the C++ language..That's what I'm doing now..although I'm not new to programming, been programming Dbase, Foxpro, Alaph4, and MSAcess VB, & VBa for 30 for over years.. so what's one more language to learn the syntax and command structure of..lol

In our plant, the IE techs programmed the PLC and DCS systems, along with the Process Control systems engineers.. so we were a little unusual in that sense, that we were afforded the opportunity to learn how the systems were designed to work, making trouble-shooting a whole lot easier..ya can't fix it right, if you don't understand how it works..This forum is great for that purpose..many people with the programming skills to help us out, and alot of great ideas to try out.. My new project is to re-create a touch lamp that I built back in the mid 70's.. It used the new JFets (at that time) and I made it use the inherent capacitance of the device to work as a proximity detector. In this way, you really didn't have to touch it, just be close enough to triger it( about 4" max distance).. The circuit was installed in a lantern ( like the old train lanterns) with a 12 volt dc lite, powered by a Ac powered 12Vdc power supply.. used a 555 timer set to one second as a one-shot to the J-K- Flop-flop to drive the power transistor for the lite..kinda like a debounce.It was quite a thing back then..If you held your hand close to it , it would flash on and off in 1 second intervals..

Looking forward to learning more about remote control and robotics...

kind Regards,

LouisR

LouisR

I was at GP, but only for 15 years before the Koch brothers descended and made a absolute mess of things.

SteveG

@patrickwd -- Into now?? I have a physicist daughter who is doing work in mineralogy and I've ended up making some lab equipment for her using Arduino in its various incarnations; several versions of microscope dark field illuminators using Adafruit neopixel strips and various mechanical arrangements for mounting them. The mounting takes some ingenuity and we've used machined acrylic, machined castings and 3D printed holders. All work reasonably well. Also a couple of specific gravity measurement setups using strain gauge load cells. They work in principle but the number of interest is small but derived by subtracting one big number from another so are subject to noise-- I'm working on it.

Regarding your interest in robots, I've been thinking that an ideal robot could be made by copying the millipede. Ideal shape for crawling into inaccessible holes and each segment is simply a repeat of the previous. Just cogitating.

I just passed my 90th birthday so working on things to keep the mind working and sometimes I think my daughter is pushing things my way to keep me busy.

foxxy

@foxy Congratulations on you longevity my friend!.. I'm 75 next month.. and I think your right, the brain is like a muscle... use it or lose it! lol

I'm in the camp of "your never to old to learn..but since I can't don't all the things I could when I was younger, I will try to pass on as much knowledge as I now posses to those that are willing to learn..Building things, troubling shooting and repairing, is what I did for a living for almost 49 years..so now I have the time , resources (money), and interest to learn the new technologies. As I worked in industrial process control for 28 of those years, I have a pretty good idea of how to use and apply those theorems to practical application..just need to get this c++ programming down so I can start to work on a few ideas I have.

You know the old saying, those that can't do, teach!...lol

Kind Regards,

LouisR

LouisR

Not completly sure who I am replying to so hope a blanket reply will do.

I can't compete in the age bit. I am a relative youngster at 67. Retired after a late career change to grazier (farming cattle. Might be rancher on your world.) My brother in law who ran a fair sized station had an accident in the yards (a cow threw him into a gate.). He was badly damaged and in rehab for months. Meantime with the help of other in laws we took on managing the farm. I was working at a coal power station at the time. They let me transition out of my projects till I was full time farmer. My brother in law has made a good recovery and is more or less independant. He still needs a lot of support though. Talk about learning curve. Some of it pretty harrowing. How to put down starving stock. Helicopter mustering, areial spraying. Drought feeding. Bores, pumps, windmills, fencing etc..

When things had returned to a sort of normal we took off do the Canning. This is a famous desert track possibly one of the most remote in the world. The track proper is 2000km. The round trip about 10,000km.

I could go on...

I don't have any automation projects on the go at present. Mostly boring pumps. I pump my water up 200m with a small solar pump. Sounds easy but has taken many iterations to make something reasonably reliable. Brushless gear motor with chain drive to a small triplex plunger pump. About 100W about 1 l/m. Current pump has been running all day every day for about 2 years. Think I have got it?

Cheers

Patrick

PWD

@patrickwd , Yep.. I think you got it this time..two year for a solar pump sound impressive to me..lol

BTW..farming, and ranching are the life blood of any community, or country for that matter.., It's great that you had the where with all to help your in laws out..oh, and don't work about that age thing, it's just a number that keeps reminding you of the fact that your not 40 anymore.. lol

But I don't let it slow me down to much.. Right now, I'm just concentrating on learning this C++ syntax and command structure..proto- typed a little project to practice on, just finished it a couple of days ago.. In essence, it was to learn how to code and how the Arduino works..( that's the technician in me..lol) can't fix it if you don't know how it works!

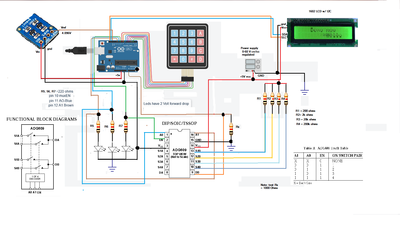

It was a project to find the value of an unknown resistor. I used a keypad to input range change, and an 1602 LCD w/anI2C adapter for readout. Also used the LM4020 voltage reference board to get a little better resolution. worked better than I expected! Anyway, I've attached a fizzle drawing of how it's put together, and a copy of the coding.Now off to do some shopping with the wife..Cheers,

kind Regards,

LouisR

LouisR

@inst-tech Impressed. I must get into TinkerCad. I think I have almost no documentation of my walking robot.

I think I need to raise a new topic in the projects space to start to describe it. Leave this introductory stuff.

Patrick

PWD

Indeed, Yes that would probably be beneficial to start a new topic to all of us interested in robotics and automation in general.. As soon as I get this C++ stuff down, I'll start to put some of my Industrial process control knowledge to work in the art of automation..Tinkercad is simple to use, and has a wide variety of components to work with..I do all my experimentation with it before I try to proto type actual components on the bread board.. saves a lot of time looking for wiring errors, component variations and limits.. and best of all, you don't have to worry about letting the "magic smoke " out!...lol

Documentation is just the technician in me, as that's Just what we do.. a proper schematic, P&ID, Loop dwg, one -line electrical, or motor elementary dwg's were essential to our being able to trouble shoot process control problems. So after 49 years of that, it's almost like breathing, lol..

Looking forward to seeing some of your projects..

King Regards,

LouisR