I'll give you both versions and explain why. This a huge data-dump below. Ask questions about any aspect that isn't clear. This is non-trivial.

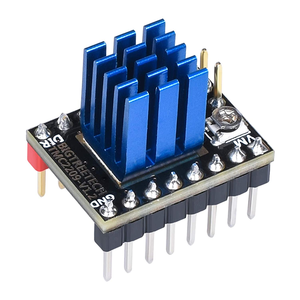

59.9625° Version - A4988

- Con - Only 1/16th Micro-stepping using A4988.

- Pro - If 59.9625° is good enough accuracy. This is the easier solution to implement. Again - the error is not cumulative. At 180, 360... it is exact. The deviation is never more than 0.0375°.

- Pro - I use these in this bot -

. This is the thread, but way too long to be worth studying for what you need - https://forum.dronebotworkshop.com/user-robot-projects/inqling-junior-robot-mapping-vision-autonomy/ I switch them from 1/16th micro-stepping real-time to have an effective gear change like a car transmission. Low for precise control and accelerating up to where it can be switched to full-steps for speed.

- Pro - It works very well and is easy to implement using pins on standard 3D-Printer breakout board shown above.

- Con - Although they are claimed to be able to handle up to 2 amps, I've never been able to get them above about 1.1 amps, but I use cheap China clones. This is important for how much torque your motor puts out.

- Pro - Chinese clones readily available. Search for A4988 on your favorite vendor - Amazon, ebay, Ali-Express, etc.

- Con - Since you said you are new to this stuff, it is non-trivial get some of the stuff under your belt to implement this.

- Here https://www.pololu.com/product/1182#:~:text=The%20A4988%20driver%20IC%20has,can%20keep%20the%20IC%20cool. is a good resource to show you:

- how to wire them to your microcontroller

- tune them to get the most power out of your motor

- to set the micro-stepping value you need - 1/16th.

- Here https://www.pololu.com/product/1182#:~:text=The%20A4988%20driver%20IC%20has,can%20keep%20the%20IC%20cool. is a good resource to show you:

59.99765625° Version - TMC2209

- Pro - 1/256th Micro-stepping (available)

- Pro - Can handle up to 2.5 amps (the maximum your steppers will handle).

- Pro - Note the voltage range allowed on these on the datasheet below. The higher the voltage you use in that range, the better.

- Con - These little break-out boards are standardized for 3D printer usage. Even though this chip is capable of 1/256th micro-stepping, the pins available on this board to control the chip (under the heat-sync) only allow you to change to 1/16th micro-stepping. This is so this board/chip can be a plug-in replacement to the typical ones found in printers (the A4988). To get the 1/256th micro-stepping you have to use their proprietary serial communications pins.

- I don't understand most of this data-sheet and don't really use it, but include it here as a reference. It explains a ton of features that you won't use - https://www.trinamic.com/fileadmin/assets/Products/ICs_Documents/TMC2209_Datasheet_V103.pdf

- Con - Although I have a set of these, I have not used them yet. I do plan to use them with the same large stepper you have. IOW, I can't be the point of the sword for you when you try to use the serial communications to access the 1/256th micro-stepping. 😆 Maybe you can be my point of the sword.

- Pro - There are Arduino drivers for this board.

- Con - Fewer vendors - "https://www.amazon.com/BIGTREETECH-Printer-Stepstick-TMC2209-Heatsink/dp/B07YW7BM68/"

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq Well you certainly know your stuff when it comes to doing these things. I have a proposition for you.

I am extremely pressed for time to solve my problem. You have been invaluable in that task. What my problem is, I can't learn this fast enough to meet a serious deadline. I am facing a demonstration of my invention next week in Florida and at the current rate I will not make it. I am very willing to pay you for your time to develop the code I need to make this all work. Are you interested? OBTW my 4988 will be here tomorrow and that is close enough for what I need because it is not cumulative. Jim

@olddude EDIT: This gentleman is an inventor and is looking for help for pay. I can't help, but if someone can I would advise asking for 50% or maybe 49% of the company as compensation. Good luck!

Am I understanding you? You were using the forum and it's members to help you develop an invention? Were you going to pay everyone that helped, or if they fixed it would you have stayed quiet?

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@zander I am more than willing to pay whatever is appropriate for help. I have not made it a secret of what I am trying to do. Just let me know what is acceptable. I am certainly not trying to cheat anyone. As I said I am willing to pay for help. I thought that I was open with you in my last reply. I need help and you seem to be very knowledgeable. I apologize if I have done something wrong. Jim

@olddude I owe you an apology, you did say in your first post you were an inventor. I doubt I can help you, and if you still have to have EXACTLY 60 degrees then nobody else can either.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@olddude No

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@zander Thank you Ron. It appears that Ing has come up with a solution using the A4988 to split the steps. He also said that the variance which is minor is not cumulative so I can live with that. I am trying to avoid using gears if possible. I am out of time and need someone who can do the code necessary to get my NEMA17 running. Are you familiar with the A4988?

@olddude Yes I am, it's a motor driver. You can find free code on Bill's YT chan.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@olddude Welcome to the forum!

The article (and associated video) that @zander mentioned for the A4988 is here: https://dronebotworkshop.com/stepper-motors-with-arduino/#Demo_4_8211_Bipolar_Stepper_with_A4988

From reading the thread, I'm wondering if you might consider using a microstepper driver (and perhaps a larger motor) instead. I used a fairly large microstepper driver in this article, but they come in all sizes. The one I have can resolve down to 40,000 steps, but I have seen them with higher resolutions: https://dronebotworkshop.com/big-stepper-motors/

😎

Bill

"Never trust a computer you can’t throw out a window." — Steve Wozniak

@dronebot-workshop Bill do you know of anyone who would be willing to help me with this project? I am in a pinch for time and I am lost in all of this. I am more than willing to pay someone for their help.

@zander Thank you Ron. It appears that Ing has come up with a solution using the A4988 to split the steps. He also said that the variance which is minor is not cumulative so I can live with that. I am trying to avoid using gears if possible. I am out of time and need someone who can do the code necessary to get my NEMA17 running. Are you familiar with the A4988?

May I offer an alternative idea/solution?

The reason I say that, is because in the past (as a Toolmaker ~20+ years ago), I actually built a machine with the same requirements, although not 60 degrees! However, the problem was the same... I needed accuracy!!

So (I didn't even know anything about microprocessors back then), what I did was just get a pneumatic cylinder to rotate the plate based on radius and stroke length to as close as I could calculate it, and then I drove a hardened dowel pin through a hardened bush that I made at the required angle, to act as some kind of a brake or holding position with a pneumatic solenoid which was controlled via a PLC - This provided the accuracy I needed!

These days we have Arduino and microcontrollers in general to get us close, so those trigonometric calculations become obsolete to get us close, however, if you have a torque requirement, in that you wish to perform some machining action on your parts at that specific rotation angle, then I would also look into an electronic disc brake / clutch, if you will, and they work great.

Just some food for thought, and good luck!

Cheers

Bill, what is an initializer? Can't find a reference anywhere?

Bill, what is an initializer? Can't find a reference anywhere?

Where do you see that term ? I couldn't find it in this thread nor in Bill's (written) article.

Anything seems possible when you don't know what you're talking about.