@inq Standard RV gauges for black and grey tanks are notoriously inaccurate which is why I put in rather expensive sensors from SeeLevel. I must have done a poor job because they are not working well at all. I will be working in that area soon and will see if there is something I can do to get them working again. I doubt I will replace them as I will be selling this RFV in about 19 months and have a good grasp of when the black tank needs to be dumped.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

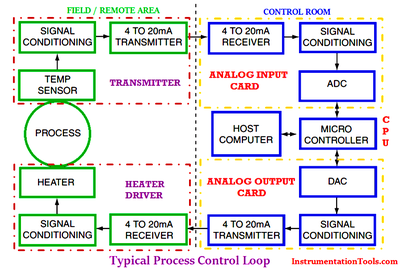

@inq , Believe it or not, the most common industrial way to measure level is with a pressure differential transmitter. (PDT).. We call all our sensors transmitters, from the old days when the signals were pneumatic, and had to be "transmitted by air pressure of 3-15 psi" to the receiver elements, or controllers.. which were also pneumatically operated. In the modern digital world of today, the instrumentation is now going digital, but the vast majority is still analog, mostly 4-20 mA from the transmitter, and converted to 1-5 volts at the input of the ADC by using a 250 ohm , 0.1% resistor. With ADC of 24 bit, and loop update time of 2 or 3 times a second, and the processor can give very accurate measurement information for as many as 128 inputs/outputs for a single controller.

this would be a typical temperature control loop..

regards,

LouisR

LouisR

@zander NO, if it is a sealed tank, then you'd have to have a access hole in the top of the tank..and I think you already stated that was a non-starter..so maybe a pressure transducer could be used to read the level in the tank.. If you need more information about how this is done, I would be happy to show you in a pictorial drawing how this is done.

regards,

LouisR

LouisR

@inst-tech Sure, if you can do some kind of measurement without creating an opening in the tank, I would love to see it.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Believe it or not, the most common industrial way to measure level is with a pressure differential transmitter.

Are they merely using head pressure? Or is there some other pressure technique, I'm missing?

The boat tanks I'm talking about might be say... 5" tall. Head pressure if the sensor is say on the outlet at the bottom... would be about 0.18 psi. I'm guessing it's possible to have high-quality pressure gauges that can measure 0 to 0.18 psi, but do you know if there is anything at our hobbyist level (say... < $10) that can handle that? 8 bit resolution would be great, but, heck... 4 bit would be better than using these ultra-sonic sensors.

VBR,

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Believe it or not, the most common industrial way to measure level is with a pressure differential transmitter.

Are they merely using head pressure? Or is there some other pressure technique, I'm missing?

Yes, they use head pressure, and industrial types are expensive.. ranges can be from vacuum to 6,000 psig, and higher for special applications like well head pressures that can be in the 10's of thousands of psi.

Not to sure if anything in the hobbyist price range, but I'm researching that possibility.

We typically measured furnace pressure down to ranges of 0-2" WC ( inches of water column) as the furnace pressure of a positive draft boiler is about 0.25" wc...lol

The challenge now would be to find a transducer in the right range with appropriate. turn down ratio, and cost.

LouisR