A recently completed project for my grandson was a fun project that brought together 3D design and printing with Arduino micro controllers and radio control to produce a easily controlled tank. The project included 56 3D printed components, 34 screws and nuts, 2 Arduino Nanos, an H-bridge driver, a 443Mhz transmitter and receiver.

The tank was designed using TurboCAD software and components were printed on Artillery X1 Sidewinder using PLA and TPU filament. The tank dimensions are 250mmL X 150mmW X 100mmH. The motors have an a metal 90:1 rear train that gives it good speed when powered from 2 16850 LI-ion batteries.

The unique items may be the tracks that are a one-piece print using TPU plastic. The track flexibility was a pleasant surprise as was the durability. The radio transmission distance was also surprising for such inexpensive devices. The tank can be controlled from more than 300 feet. How much more is unknown as I couldn't see the tank any more when it was commanded to return.

In research for the project I picked up a tip that made the software that reads the joystick and creates the control values for the motors. That tip was just to rotate the joystick 45 degrees. By doing this the X and Y outputs from the joystick line up with the left and right motors. This little tip saved me hours of programming frustration.

Here are a couple of pictures and a video.

https://photos.app.goo.gl/kKXDjHXEcycb1VTT7

That's really awesome sir. 😀 I am very much interested in making these cool stuff. I am learning the Arduino Uno now and am using them with different sensors and other components.

Then, I will start off with 3D printing and modelling such remote controlled bots.

I will need the much required guidance for my future projects from this Forum.

Hope you will help me. I might just ask a few doubts and questions. 🙂

Thanks 😀

By the way, the software you used was Turbocad. Is it equivalent to Autodesk AutoCAD Mechanical?

Or any other AutoCad type?

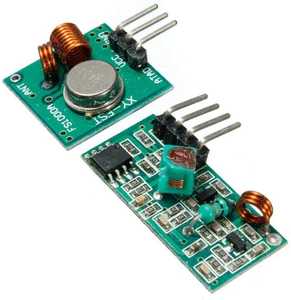

What radio are you using for the T/R functions?

SteveG

Yes, TurboCAD is another design CAD software that has been around for a while and at one point was very reasonably priced. Given all of the quality free CAD software out there now I wouldn't recommend TurboCAD for 3D printing for someone starting to learn CAD. I have an older version (2017) and it has a few quirks especially when it creates STL files for the printer. But as with a lot of things once you get use to something one way it is difficult to justify the time to learn a whole new method so its my go-to design software.

Given the tank design didn't need to send any information back to the controller I chose the very inexpensive (less than $3.00 w/ shipping ) transmitter and reviver from Banggood.

I was expecting this to be the most problematic aspect of the build but was very delighted with the range, its forgiveness of voltage fluctuations and noise tolerance when used around microcontrollers and brushed motors. Using the Radiohead library made it very simple to send the joystick values from the controller to the tank.

So, which software do you recommend a beginner for creating designs for 3D printing?

I have heard about AutoCad, Fusion 360, Solidworks, Inventor, etc.

Which one should a beginner learn?

You may want to look at the decision as to which software to start with in terms of the quantity and frequency you plan to design, and the envisioned complexity of your designs. There are a lot of crossover aspects of CAD software that once learned can be transferred between the various packages. However, they all have unique interfaces and typically the more complexity the software can handle the steeper the learning curve.

Fusion 360 is free and is very powerful. However, the learning curve is quite steep. If you are thinking of potentially doing CAD design professionally this could be a good choice.

TinkerCAD is at the opposite end of the scale. It is more intuitive to use but lacks some of the more advanced features. However, I have used it to create some relative complicated designs very quickly with with little time invested in learning its use.

FreeCAD, although I have not used it and only watched tutorials seems to be somewhat in the middle. It also has the advantage of being supported by a freeware group that is unlikely to stop the "free" part of the software and upsell you to a very expensive CAD package. This is the most likely software I will switch to when I get fed up with TurboCAD's price increases (my first TurboCAD package cost $39, now it's $200)

There are many other CAD packages available that other members have more experience in their use and can comment on.

I just recently acquired a printer (FLSUN 5Q) without any experience of using one at all. It is many many years since I did any technical drawings but I wasn't really interested in printing other people's designs. I did try TinkerCAD as it was supposed to be 'intuitive' but I found it quite difficult to get my head around it. As Ruplicator notes, and I read this in several reviews, TinkerCAD quickly shows its limitations. So having read the very positive reviews of FreeCAD I decided to start up the learning curve. With the help of some excellent tutorials on YouTube, DrVAX, and FreeCAD Academy were the two main ones I used, I a can now produce an STL file for printing that produces parts reasonably aligned with my intentions. Using FreeCAD was a bit frustrating to begin with but the Eureka moment does come and it does not take so long to arrive.

I recommend large quantities of coffee and thick carpet to chew on during the initial stages.

Okay sir. Thanks for your reply. I will surely try FreeCad. I will try to start off with that software soon. 🙂