I'm not sure why you think you still need potentiometer ?

Thanks for the comments. I think I need to experiment with MOSFETs on TinkerCAD to learn more about them. I am not sure how power going through them can be controlled without some kind of a pot unless a controller like Arduino can be programmed to be a virtual pot; I need to search on that as well. I have found a dimming sketch already. I am working on a simulation with the MOSFET with and without Arduino to see what I can get,

The PWM signal fed into the MOSFET switches it on and off quickly (and efficiently). This effect REPLACES the potentiometer which always receives full voltage from the battery and only delivers part of it to the load (i.e. your heating element).

This results in a series of full power bursts through the MOSFET from the battery to the heater. The MOSFET and PWM signal together replace the pot in the circuit. This allows the micro controller to make adjustments to the power delivered to the load by varying the length of the pulses of power.

Try looking up terms like PWM and "duty cycle" to help you understand how these pulses are created and how they deliver full power or no power pulses to the load to adjust the total power delivered over a time period.

Anything seems possible when you don't know what you're talking about.

The PWM signal fed into the MOSFET switches it on and off quickly (and efficiently). This effect REPLACES the potentiometer which always receives full voltage from the battery and only delivers part of it to the load (i.e. your heating element).

This results in a series of full power bursts through the MOSFET from the battery to the heater. The MOSFET and PWM signal together replace the pot in the circuit. This allows the micro controller to make adjustments to the power delivered to the load by varying the length of the pulses of power.

Try looking up terms like PWM and "duty cycle" to help you understand how these pulses are created and how they deliver full power or no power pulses to the load to adjust the total power delivered over a time period.

I think I understand what you are saying. A MOSFET is a switch that can open and close as commanded by a PWM input; and a micro controller (Arduino or similar) can be programmed to vary its PWM duty cycle based on programmed conditions, say when temp+humidity reaches a certain level, thereby opening and closing the MOFSET gate (?) in harmony with the PW Modulation (duty cycle), allowing the external power to flow through the gate (?) and into the load.

Because the control board can be programmed to pulsate a signal out of one of its digital out ports then a physical pot (analog or digital) is not needed.

Is this almost right?

Yes, the PWM switching the MOSFET on and off controls the amount of power delivered to the load.

On the Arduino, you can apply a PWM from any of several different pins. The Arduino manages the frequency internally, all you need do is set the "on/off" ratio.

This ratio is expressed as an integer from 0 to 255. So 0 means never on and 255 means never off. A value such as 23 would mean that power would be applied 23/256th of the time and not applied (256-23)/256th of the time, or, roughly 9% of the time. To a resistive load fed at 12V, this would be equivalent to an constant voltage of 23/256 x 12V = a bit over 1V.

So you can see how power can be adjusted easily and over a fairly wide range. You'll spend FAR more time deciding when and how much power you want to apply to the heater. When it comes time to deliver, say 10% power to the heater, you'd only need the command:

analogWrite(heaterPin,25);

where 25 = 10% x 256 (rounded down to the nearest integer). to start the MOSFET delivering full power for 10% of the time to the heater.

Anything seems possible when you don't know what you're talking about.

@farzad_k - Did you end up with a solution you liked? It appears that most of the thread was related to the heater control system and @will got you squared away! I wasn't clear what you ended up with the sensor side.

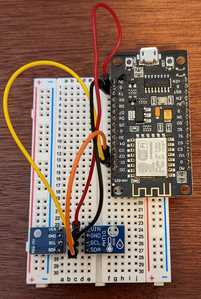

I stopped using DHT11, DHT22 as my students seemed to be great at destroying them. Even I had a weather station that was happily going for weeks and the DHT22... just stopped working out of the blue. I now use AHT10. They seem to work nicely and haven't had a single one go bad... yet. But I have faith in my students will find a way! 😆

https://forum.dronebotworkshop.com/show-tell/inqweather-forecasting-weather-station/

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq That project fell on the wayside, I am afraid, and while I have all the parts I have yet to put them together. I will keep your notes in mind. Thanks.