Hi @Ron,

In this case it's not moving along a line. Instead the commercial product uses a controlled trolling motor mounted at the bow (with a GPS) to maintain the bow at an approximately stationary position (using GPS not magnetic field). This works well enough, but does not control the heading of the boat, which is what the OP was wanting to do.

@headingholder Stationary? I don't remember if mine had a stationary mode, I know it moved, I was following (roughly) an underwater ridge. Had I waited one year the new models had contour following. Although the heading could be controlled from the front, it is slower to respond than adding an additional bidirectional thruster at the back. It'a a poor man's stern thruster.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@Ron Yes, I think Minn-Kota's is called Spot Lock, and Motorguide and Garmin have a similar feature for their trolling motors as well - to just hold position, and the motors are usually mounted on the bow. The mode of operation is well described in the "loiter" function for ardupilot:

https://ardupilot.org/rover/docs/loiter-mode.html

What did you use for your bidirectional thruster at the back? Did you have a control system working it?

I think somewhere along the way you all scared him off. I read the first couple of pages and skimmed the rest. So I could easily have missed something. He said he just didn't want the front poles to be taken out by trees on the shoreline. I'm not sure where someone got wrapped around the propeller and thought accuracy was an issue. A Magnetometer is easily good to within a degree or two. I'd bet he'd be happy with +/- 10 degrees.

I'd think all that was needed:

- ESP8266 - The WiFi wouldn't be needed, but could later add WiFi features if desired.

- Magnetometer

- Momentary button

- Couple of Mosfets - I don't know how to pick these things, but I was thinking running a couple of these in parallel (in each direction) will easily handle his 40 amps at whatever voltage he wants 12V, 24V or 36V. " https://www.amazon.com/BOJACK-IRF540-Transistors-IRF540N-N-Channel/dp/B082J2Y16 7"

- I'd even punt the potentiometer.

Grand total: about $15

Procedure:

- Simply point the boat in the desired direction and press the button

- The MPU gets the Mag reading, calculates the North

- As the boat swings off that angle PWM the motor in the opposite direction.

- When he wants disable it, press the button again.

Easy-peasy!

VBR,

Inq

Hi @inq,

Thank-you, I think you pretty clearly identified a solution, and that was a good idea to punt the pot, you are right, a momentary press at the desired heading is simpler and works better.

Ok, it's been about 20 years since I programmed a microcontroller (nothing has changed, right? 🙂 ). Off down the rabbit hole!

@headingholder I didn't have any, I was referring to the proposed solution.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

I think somewhere along the way you all scared him off. I read the first couple of pages and skimmed the rest. So I could easily have missed something. He said he just didn't want the front poles to be taken out by trees on the shoreline. I'm not sure where someone got wrapped around the propeller and thought accuracy was an issue. A Magnetometer is easily good to within a degree or two. I'd bet he'd be happy with +/- 10 degrees.

I'd think all that was needed:

- ESP8266 - The WiFi wouldn't be needed, but could later add WiFi features if desired.

- Magnetometer

- Momentary button

- Couple of Mosfets - I don't know how to pick these things, but I was thinking running a couple of these in parallel (in each direction) will easily handle his 40 amps at whatever voltage he wants 12V, 24V or 36V. " https://www.amazon.com/BOJACK-IRF540-Transistors-IRF540N-N-Channel/dp/B082J2Y16 7"

- I'd even punt the potentiometer.

Grand total: about $15

Procedure:

- Simply point the boat in the desired direction and press the button

- The MPU gets the Mag reading, calculates the North

- As the boat swings off that angle PWM the motor in the opposite direction.

- When he wants disable it, press the button again.

Easy-peasy!

VBR,

Inq

Hi @inq,

Thank-you, I think you pretty clearly identified a solution, and that was a good idea to punt the pot, you are right, a momentary press at the desired heading is simpler and works better.

Ok, it's been about 20 years since I programmed a microcontroller (nothing has changed, right? 🙂 ). Off down the rabbit hole!

Hi @Inq,

Could I just confirm your thinking for the motor drive, are you saying that the PWM signal comes out from the ESP8266, through the MOSFET directly to the motor leads (the MOSFET is just amplifying the PWM signal from the 8266)? The reason I ask is that it seems that most people are using commercial ESC's (like this one) to interface with trolling motors.

By the way, this is the motor I decided to try, max current of 17A at 12V.

HH

Hi @Inq,

Could I just confirm your thinking for the motor drive, are you saying that the PWM signal comes out from the ESP8266, through the MOSFET directly to the motor leads (the MOSFET is just amplifying the PWM signal from the 8266)? The reason I ask is that it seems that most people are using commercial ESC's (like this one) to interface with trolling motors.

By the way, this is the motor I decided to try, max current of 17A at 12V.

HH

I'm the last one to trust when it comes to hardware and amplification has other connotations.

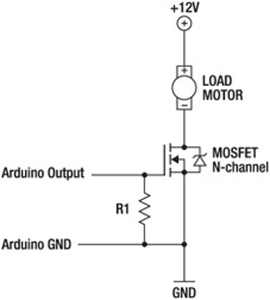

SIMPLISTICALLY... I understand that a Mosfet lets you switch on/off a large voltage/current using the logic pin of a microprocessor. That if you pick the Mosfet correctly (being fully activated) with the logic voltage of 3.3V (in the case of an ESP8266) it will happily drive a motor.

BUT... two things...

- Mosfet can only run voltage one way. So you just have to use 2 Mosfets and 2 PWM pins making sure to only drive one or the other of course.

- There is something also about back EMF because of the coils in the motor. I have mixed references saying Mosfets have diodes built-in and other saying you have to have a diode added to the circuit to make sure no reverse current goes through the Mosfet and destroys it (per #1).

Mosfets Chapter 2-2 Interfacing Arduino, Arduino Robotics

A MOSFET is a type of transistor that is voltage-driven instead of current-driven like the BJT. This type of switch is also capable of extremely high PWM speeds and typically has very low internal resistance, making them ideal for use in motor-controllers. Mosfets usually include an internal protection diode (as shown in Figure 2-11) to isolate the output voltages from the input signal and protect from Back-EMF produced by the load, so it is generally acceptable to interface the Arduino directly to a MOSFET switch; this is one less part that must be added into the circuit.

In my simplistic mind, you need (2 resistors and 2 Mosfets). Now... maybe the more hardware expert people like @will, @davee and @robotbuilder might chime in and correct my simplicity.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

I think I'd go with $21 sure thing.

But if you look at your board, It looks to be using 8 Mosfets = 4 for forward and 4 for reverse. They use 4 in parallel to share the load because they're small. They probably have some other hardware to make sure which 4 are being used based on an input pin. I imagine it has a PWM input pin for speed and a second pin for direction.

I don't know what the capacitors are for.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq FYI @headingholder The capacitors are to absorb any peaks. Those 4 parallel Mosfets are a bad idea. If one fails at full load, the remaining 3 will not be able to support the now higher load thru each. Get one that can do the job. I have Power Mosfets 30V at 62A from Amazon $8 CDN for 5.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@inq FYI @headingholder The capacitors are to absorb any peaks. Those 4 parallel Mosfets are a bad idea. If one fails at full load, the remaining 3 will not be able to support the now higher load thru each. Get one that can do the job. I have Power Mosfets 30V at 62A from Amazon $8 CDN for 5.

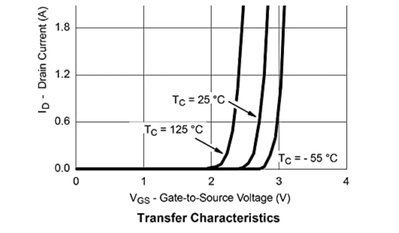

I don't seem to get the specifications right... will it be fully "energized" (not that I understand exactly what this means) but my first couple attempts getting Mosfets didn't work to well with 3.3V logic pins. Can you shoot me a link if these work with 3.3V?

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Maybe this is the MOSFET @Ron was referring to,

(Pack of 5) IRLB8721PBF TO-220(TO-220AB) MOSFET 30V 62A Power N-Channel Transistor Marking IRLB8721

and if so, I believe "Gate-Source Threshold voltage" is the relevant spec, and it is listed as between 1 - 2.5V I think that means it should work.

@inq I have never been able to use mouser or digikey, too complicated so the mosfets I own were either recommended by someone or I just searched amazon.

I don't know if any of my mosfets work with 3.3V as so far everything has been 5V.

I will go through all my mosfets and see what I can learn from online documentation, and then follow that up with a test. That will take some time though.

Also, I may be 100% wrong, but when a Mosfet turns on it is fully on beyond a threshold trigger voltage.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@headingholder FYI @Inq It looks like it does work with 3.3, here is a link

https://www.adafruit.com/product/355

This part of that link says it all

The threshold voltage is also very low, less than 2.5V so you can control it directly from a microcontroller running on 2.8V, 3.3V, or 5V logic.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@headingholder Maybe I am lacking something in my education but although I know trolling motors like any other frequent user of one does, my electronics education was only restarted recently after a 60+ year layoff. Here is my problem.

If as I understand it the Mosfet turns on almost at full power at a specific gate voltage, how do you control the speed? If it's a PWM type situation, is that Mosfet capable of switching on and off fast enough. I assume that at 50% throttle power then the duty cycle has to be 50% or half the time on, half off. I can see that working, but I know my motors could be slowed to the point that the prop rotated at maybe less than 1 rev per second. It seems to me that the Mosfet will have some spec as to how fast it can cycle between off and on. Does anyone know what that spec is called, and does the Mosfet in question meet that spec?

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.