I want to construct a +12v -12v dual power supply to feed less than 500 mA to a milliOhmmeter circuit. I think it would be ideal to use a low profile PCB mounted 30V transformer with a center tap. All such transformers I have found have two identical secondary windings instead of a single, center tapped winding. Logic tells me that connecting the two center leads would create what i want. Can someone verify my thinking?

The first thing you want to do is to get a hold of is the wiring diagram for the transformer(s) that you are considering. Most of those "dual winding" designs can be wired differently on the secondary side to provide a center tap at half the current or parallel windings at full current.

The primary windings often have a similar arrangement, so they can accommodate 120 or 240 VAC.

But the wiring diagram is essential, as you can't just determine all of this info from ohmmeter readings (you could, but you might wire them out of phase). The wiring diagram will have hookup diagrams for all the different configurations that your transformer is capable of using.

😎

Bill

"Never trust a computer you can’t throw out a window." — Steve Wozniak

Hi @cecil,

Bill (@dronebot-workshop) is certainly correct in saying that a wiring diagram or data sheet would be make life a lot easier. I think what I am suggesting below is correct and safe, but obviously welcome comments or corrections.

As Bill has mentioned, sometimes windings are intentionally paralled. Wiring windings in parallel, the wrong way round, will indeed end very badly. This application is looking to wire them in series, which should be less hazardous.

=====

If you have a transformer, with (say) 2 x 12Vac windings, that are clearly identified, but it is not clear about their relative phasing, then there are only two 'different' possibilities for series connection that might need to be to tried.

Please note this is only safe if you have checked each winding is NOT connected to any other winding - so do that first!!

--------

Let's say you label the first winding's pins A and B, and the second winding's pins C and D.

--------

Note, sometimes manufacturers put a dot of spot of paint by the start of each winding. If so, each of the two windings should have just one pin with a dot. And if this is also so, choose these pins to be A and C.

----------

Before proceeding, use an AC voltmeter to check that the output across A - B is 12Vac, across C-D is 12Vac and across A-C is roughly zero.

(You may get a small reading for A-C, but it should be much less than 12V. If the voltage is substantial, do not proceed.)

----------

As it easy to make a mistake when making connections, I sometimes initially use a resistor instead of wire for the first test, and check some voltages etc. Then a mistake is only likely to cause a small current to flow, not a 'bang'.

The next steps involve connecting windings. It should be ok to connect with a wire, but a safer alternative is to use a resistor in the range of 100 Ohms to 1kOhm. This way, any 'unexpected' current flow is limited, but the voltmeter should still give the same readings.

Obviously, the resistor will need to be replaced by a wire in the final application.

---------

Temporarily connect B to C, and use an AC voltmeter to measure A to D.

If the voltage is around 24V, you have the arrangement you want, with B to C being the centre tap.

But if the voltage is around 0V, then they are out of phase. Remove the connection from B to C, and make a connection from B to D. Then measure the voltage from A to C .... hopefully it will be 24V ac.

------

I think this procedure is safe and clear - but as always, you undertake it at your own risk.

Please take care, remembering the voltages on the primary can be lethal.

Best wishes, Dave

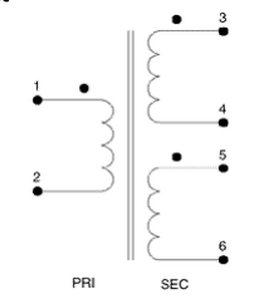

@davee I've checked the datasheets and the schematics.

This is what I mean by two identical secondary windings. I sounds like I can create a center tap by connecting the secondary windings in series. Thanks very much for the confirmation. By the way I always use my lightbulb current limiter when messing with unknown circuits.

@cecil That is probably ok, but it does depend on how the two secondary coils are wound. Worst case they are opposite so the center tap is at near zero, but AFAIK there is only one way to find out, although I would urge you to wait for @davee to chime in, he is more experienced in this field.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Yes, the transformer looks like the kind of diagram I had in mind.

Hopefully, if you equate A=3, B=4, C=5, D=6 from my mini-sermon (A-D) to your diagram (pins 3-6) it will make sense.

As I mentioned, when a transformer has 2 or more windings, it is common, but not guaranteed, to show the start of each winding with a dot or similar.

When transformers have high voltage windings, then extra care is needed to minimise the voltage difference between turns of different windings that are physically close together, to minimise the chance of flashover.

In general, as Ron suggests, you need to be careful to match the transformer design with the specific usage, but as your secondaries are only producing 12V per winding, you would be unlucky to have a problem in this case. Ideally, a commercial transformer will have some textual information in the data sheet, to support the usage you intend, but I am guessing this is not possible in this case. Hopefully if you join 4 to 5 for the centre tap, all will be well.

Of course, a mains transformer should have good (typically 'double') insulation between the primary and the secondary for obvious safety reasons.

Sometimes secondaries also have extra insulation between each other, but probably not much at only 12Vac per winding.

Take care and hopefully all be well, but obviously everything you do is at your own risk.

Best wishes, Dave

@davee Thanks again. With your help I think I have clear picture.

Before deciding to buy a transformer I rumaged through several pieces of hoarded equipment to salvage a transformer I already have. I didn't find anything suitable for the milliohmmeter but I did pull one that I may want to pick your brain about in the future.