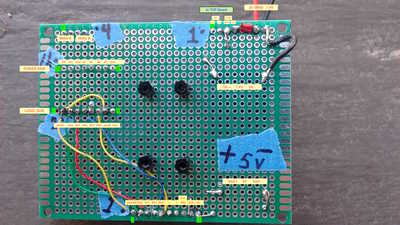

Hi! I've made some more progress, if one can call it that. Please see photo. Yes, the soldering is a mess. I'm using an inexpensive kit with an iron, extra tips, and rosin core solder (lead+tin). It also included a solder pump, which is good since I've used it a lot. I don't have any separate flux, but some braid wick I ordered just came in. It might be worth trying.

Thanks very much for suggestions from @codecage and @davee regarding labeling the actual board, and making lists of what connections go where. I've kept up my spreadsheet for that purpose.

I've put in sockets for my motor controller, and for various connectors. Soldering the header pins is something I can do now, with practice.

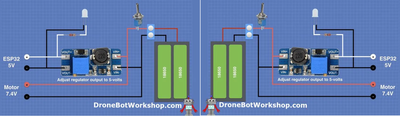

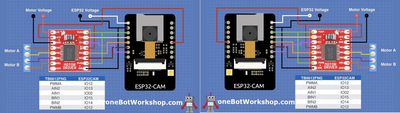

My current problem is, how do I attach one, two or more wires to the pins on the back of the board? I have looked at the stills and video from @dronebot-workshop in ESP32-CAM Robot Car many times and I still cannot see the detail to know how the extra wires are connected. I am assuming they are soldered onto the top of the original blob of solder. I'm attempting to do the same but that's where my problems start.

Sometimes I make a good connection. Sometimes all the solder originally on the pin jumps up onto my iron, leaving none or very little for a good connection. Sometimes I make a solder bridge across two or even three pins. I can see how this is funny, except for me at the time. I have spent more time removing solder than adding it. 😥

Using a multi-meter set to Continuity, I found some adjacent pins were connected that shouldn't be, but only very weakly. That is, my meter made a very wimpy warble instead of the normal continuous tone of a good connection. For these, I cut in between the pins with a small utility knife. Does anyone else do this? Is this a acceptable practice?

I recently saw an Andreas Spiess video on wire wrapping, and thought of @codecage and his experience. I'm not quite ready to go there, but it's a thought.

Cheers, John

In theory, theory and practice are the same.

In practice, they're different.

Two suggestions

1) for multiple connections to a single pin, solder an extension piece of bare wire off in a safe direction on the board (with solder on intermediate unused holes) and then solder the other wires to that. The extra length and solder will help keep the main joint at the pin cooler and will prevent it from coming off adding new wires and the bare wire provides a convenient area to solder.

2) take a picture of the "front" (top side) of the board, reverse it from left to right and print it at about the same size as your perf-board. That will give you a solid reference of what part/pin you're soldering and has saved me much grief and confusion in the past.

hah

Anything seems possible when you don't know what you're talking about.

OK, thanks. #1 sounds promising and I will give it a shot. To be honest, I did say "multiple" since I never seem to have enough Ground pins, but I have problems even attaching one (tiny) wire to the pin. Still, I need to start somewhere, and am willing to practice.

#2 - I hadn't thought of that. I do take pictures of both sides, but hadn't thought of reversing it. Good tip. - John

In theory, theory and practice are the same.

In practice, they're different.

If you lay out the bare wire and solder it to the perfboard first, then you can bend the end down to TOUCH the pin. With them touching, your soldering task is simple and without needing to hold anything by hand you have bags of space (and angles) to choose from while soldering to the pin.

Anything seems possible when you don't know what you're talking about.

Sometimes I make a good connection. Sometimes all the solder originally on the pin jumps up onto my iron, leaving none or very little for a good connection. Sometimes I make a solder bridge across two or even three pins. I can see how this is funny, except for me at the time. I have spent more time removing solder than adding it.

I am tempted to make a video to show how to solder effectively but I suspect the internet already has plenty of examples. It took me some time and many hours of practice to become good at it. A hint is that solder will flow toward the heat. I also did a lot of bronze welding of metal ladders using an oxygen/acetylene gas torch instead of a soldering iron. The principles are similar. You eventually learn to know where to apply the heat and for how long. There are tricks such as applying solder to both surfaces (eg. two ends of a two wires to be connected) then holding them together, apply the soldering iron and quickly removing it when the solder on both flow together.

I was also going to suggest the reverse from left to right of a circuit diagram. I even began to color code a complete wiring solution for your problem but as I couldn't test it I thought maybe to risky if I got it wrong.

I think Bill could have shown the actual wiring on the back of his board. The still images were mostly covered with his hands and of course the wire connections were a tangle and thus not all that easy to follow.

To enlarge right click image and choose Open link in new window.

I am tempted to make a video to show how to solder effectively but I suspect the internet already has plenty of examples.

I'm sure there are several, however I'm wondering after reading this thread if a video on wiring things up with perfboard would be of any interest?

I think Bill could have shown the actual wiring on the back of his board. The still images were mostly covered with his hands and of course the wire connections were a tangle and thus not all that easy to follow.

Yes, that's probably true, I should have done that. Again, perhaps I should so a video on the subject?

Here is how I wire perfboard:

- I fiddle around with the component placement until I like the way it is laid out. There's actually a science to it, most of it common sense.

- Once I like where everything is located, I make sure it stays down. Resistors and capacitors are easy, just bend the leads. I use sockets for modules and ICs, so I've often used masking tape to temporarily hold them down.

I do all the power wiring first, i.e. the VCC and Ground connections. I try and use only one wire for all the Grounds, and another wire for each voltage connection. For these connections, I use 22 gauge solid wire, colour-coded.

The way I only use one wire is as follows:

- I determine the length of wire it would take to "snake" between the power and ground connections. I then cut a piece, with a generous amount to spare

- I strip off a big amount of insulation from one end, the amount depends upon how many connections I need to make.

- I then strip a small amount of the other end, just enough to use to make my first connection in my daisy-chain of connections.

- I make that connection and solder it.

- Then I determine where the next connection (or possibly a few connections) are, and at what point in the wire they will be at.

- I then strip the insulation at these points, just by making a cut with my strippers. I then push back the insulation towards the other end of the wire, the end where I stripped off a lot of insulation.

- I solder the next connection in the daisy-chain and repeat.

I continue this until all the power wires are connected.

I then use the same technique for data wires, but using 30 gauge "wirewrap" wire. I don't actually wirewrap them, I just solder them in the same daisy-chain fashion.

When I need to ground something, I connect to a point in my power daisy chain that I have left available for that purpose. Usually the lead of a capacitor or resistor.

I also save the insulation from the 22 gauge wire, as it can be reused to insulate capacitor and resistor leads.

A good set of wire strippers are essential for this, especially when working with 30 gauge wire. As are a good set of snippers to trim the excess wire from leads (wear safety glasses when you do this, those things are sharp and travel at high velocity).

And, of course, a decent iron with a small tip!

Hope that is of some help, once again let me know if you think its worthy of a video. I'll make one if there is enough interest.

😎

Bill

"Never trust a computer you can’t throw out a window." — Steve Wozniak

I fiddle around with the component placement until I like the way it is laid out. There's actually a science to it, most of it common sense.

Thanks very much for your detailed reply. OK, so lay the components out, tape them if needed.

Then solder all the pins for the sockets? Or, just keep them taped in place until after snaking the ground wire around?

I believe I understand the rest of the steps. I will practice with a small piece of perfboard I reserved for practice.

As for a video showing some of these techniques, yes, I would definitely watch it. I may not be the best person to ask, though, since I already watch all of your videos. Perhaps others on the forum will chime in too. Anyone else want to level up your perfboard and soldering skills?

In theory, theory and practice are the same.

In practice, they're different.

Then solder all the pins for the sockets? Or, just keep them taped in place until after snaking the ground wire around?

No, you don't solder all the pins.

After you tape down the components like IC sockets, headers and connectors, you just start snaking the power and ground wires.

Every IC and module will have at least one power and ground connection, and those two connections will hold down the component so that you can solder the remaining pins later when you run the data and signal wires. Headers and connectors usually have at least a ground pin, which is sufficient to hold them down.

Bottom line - you want to only solder a pin once, never twice.

😎

Bill

"Never trust a computer you can’t throw out a window." — Steve Wozniak

@dronebot-workshop Solder pins once. Got it. Thank you for that. 🙂

In theory, theory and practice are the same.

In practice, they're different.

@robotbuilder - Thanks for the tips! As a follow-up, I'd say I tried to incorporate suggestions from you and some others, @codecage, @dronebot-workshop. I'm making progress.

Specifically on pictures as guides, I used them a lot, front and back. I did reverse some, as you suggested. I did continue to make some mistakes, but got better at it, with practice. When my motors could only turn left, but not right, I used my new logic probe to verify motor voltage, anomalies with Motor A and B out, to the Ain1, referred to diagrams and my photos, then finally found the wire that had come loose! (For more dull detail, see First successful robocar, done!).

As for more articles and videos on assembly and wiring with perfboard, discrete components, sockets, wires, they would help, yes, very much. However, I know there are other topics of interest, too, so it's tough to balance. Cheers, John

In theory, theory and practice are the same.

In practice, they're different.