Thank you. More reasons for me to start using LiFePo4. 🙂

I did find some 18650's with good reviews and I'm going to take the risk and see.

I guess they won't be 1800 mAh, but even 1200 mAh would also be enough for me.

Also it's a relatively cheap and easy way of getting some experience with this type of battery..

BTW, I found a resource of "trustworthy" AA LiFePo4 batteries of 700mAh from some year ago.

That's 90mAH / cm3

An 18650 = 16.5 m3 so could be roughly around 1500 mAh (overly simplified I know..)

We'll see.

I'll try to remember to post my experiences 🙂

Thanks again for your advise.

@timo88 I think those numbers are realistic, 1500 maximum for 18650. REMEMBER to use either a buck converter or linear voltage regulator to drop the voltage. I often use a buck connected to a linear for optimal settings. I am sending you a few links that have reliable info. The larger batteries of 12V, 24V, 48V are just 4, 8, 16 3.2V cells wired in series so the basics are the same. These are similar to my batteries. LINK This looks legit LINK as does LINK

this site is excellent if you live in the USA LINK but it is also educational.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi @inq

I've also used these things - https://www.ebay.com/itm/254464721220 . I'm not a hardware guy, so I don't know if these are the most efficient things for the job. That would be a @davee type question. But for my purposes they're dirt cheap and will utilize a single 18650 over its full range.

A quick search revealed this data sheet ...

https://github.com/firefly/thirdparty-datasheets/blob/main/10a45b.pdf

Most switching power supplies use a combination of inductance and capacitance ... capacitor only types are relatively rare ... the only exception that immediately comes to mind is Maxim used to have a line of products, mainly to generate about +/-12V for RS232 driver chips from 5V line, but normally they are regarded as noisy and inefficient.

I didn't see any mention of efficiency or of the quality of the power, in the data sheet, so not a lot to go on.

So, if it works for your application, great ... otherwise there are alternatives, though they will be larger.

Best wishes all, Dave

@zander I'm impressed with your Li battery experience. My interest is for power tool batteries, both converting tool packs and chargers from NIMH to Li and rebuilding Li packs. Now I want to build nominal 12V and 20V chargers that cut off charge at 3.7-3.9V per cell for storage purposes. I do it now, manually, but convenience would improve if I could just plop the packs into a charger slot. I do not use the tools heavily or year round and I think I could replace cells less often if I didn't charge them full and then let them sit, or leave them in the charger at full capacity all the time. I won't hijack this thread with my questions. But i did want to say this: I have found Liionwholesale.com to be a reliable supplier of high quality 18650 cells. Of course, I'm more interested in cells with higher discharge capacity than those one can salvage from laptop packs.

On the other hand, I might try migrating away from lead acid cells in my UPSs. It seems LiFePO4 makes that viable, though I haven't looked into it very much. I used to buy 12V 7Ah cells in cases of 24, but now I just need half a dozen every three years or so, but still . . . .

@cecil Thanks, but I am just standing on the shoulders of other, more knowledgeable folks. I did a quick check of the Liionwholesale.com site, and they look and read like all the others. Might be true might not. Once I am moved, my workbenches are built, and I am well enough, I will do a formal test of several batteries I have since I now have a capacity tester and will also do a capacity test the old-fashioned way. I am very certain the 5,000mAh 18650s are NOT 5,000, I am even skeptical of my 3,000 or 3,500 which I have and your Liionwholesale.com sells as well.

A good reliable resource is Battery University. In terms of capacity check the LiFePO4 is

| Specific energy (capacity) | 90–120Wh/kg |

Just do the math to determine if the claims are true.

If you are looking for a specific discharge rate, the charts at Battery University also list that spec.

As for your question re Lithium vs lead, YES, Lithium lifetime cost is less than lead and you can do things with Lithium that you can do with lead like charge them in a linear fashion and very fast at that. That is a huge benefit for solar charging.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@cecil I just got this in my email from DigiKey, not sure if it helps but it is related LINK You may need to change from CA to COM

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@zander The protection ICs in that link are for single cells only and are limited to <1mA. But it does show that some of the LiIon battery ICs are adjustable. I need to find one for charging 3S and 5S packs. Or find someone here clever enough to modify existing chargers to cut off charging at 11V rather than 12.6V for 3S packs and at 18V rather than 21V for 5S packs. Chargers also top off cells that have self discharged while being left plugged into the charger. My ghetto solution to defeat this whould be to operate the charger via a $5 AC timer, after learning the charging time to reach storage charge level for various packs.

This is only needed to utilize the dedicated receptacle on the charger that allows easy insertion of a pack. Presently I survey all my packs every 3-4 months and adjust their charge back to storage level. I can do this with a charger that has a storage level option but requires various fiddley bits to make contact with various styles of packs. I could buy various inexpensive chargers for my pack styles just to get duplicate receptacles but would still need to replace or modify the circuitry inside. In my mind it would be more elegant and save space if I could modify my existing chargers with switches that would designate either full charge or storage charge.

If left to my own rudimentry DIY devices, I would try to add a voltage regulator circuit that could be switched in to interrupt the normal output. For example, for 5S packs the regulator would limit the charging voltage to that needed to charge the pack to 18V and no more. Alas, this could prevent the BMS from balancing the cells-- another detail to remedy. I realize it is better to wait until someone with real electronics knowledge tackles the problem.

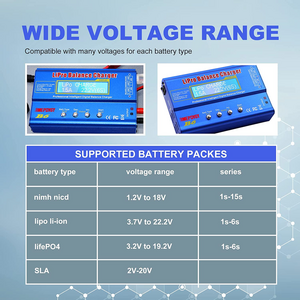

@cecil Sorry, I am not sure if I am fully understanding you. What I do know is that a DIY solution will be extremely dangerous if done incorrectly, and even if you only destroy a small number of cells (3 minimum), you are quickly approaching the cost of the professional charger I use. It handles many chemistries, can balance, and is worth every penny I paid. Here is the Amazon link in Canada, it is sold out like most electronics today LINK I paid $55.97 CDN (about $42 USD) plus tax and can sleep at night with batteries being charged.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

I need to find one for charging 3S and 5S packs. Or find someone here clever enough to modify existing chargers to cut off charging at 11V rather than 12.6V for 3S packs and at 18V rather than 21V for 5S packs. Chargers also top off cells that have self discharged while being left plugged into the charger.

I've only briefly skimmed the posts in this thread, so I might have missed all of your requirements. It seems I recall some post about storage voltage. Anyway, if you look into the Remote Control Aircraft type chargers they typically work with 1S through 6S, have settings for various chemistries, have balancing charge capability, run down tests so you can determine capacity and have the ability to charge/drain till reaching storage voltage. I have one of the cheaper ones that does all those things.

This particular model is very popular and there are many other China companies making exact clones that are junk, but look exactly the same. So do the due diligence to find which ones are authentic versus knock-offs. Also, I'd recommend purchasing from someone you can return at the drop of a hat.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@zander Actually I have and use a B6 charger, an authentic one with a serial number I've registered. I also have a professional Opus charger that takes 4 cells at a time. So obtaining a storage level charge is not the problem. I just don't have the convenience of dropping various battery packs into a form fitting receptacle and walking away, and not having to come back at any particular time.

I am aware of the LiIon fire danger. If I ever make or modify a charger I'll test it outside on concrete.

@cecil The one I have handles lots of different battery types, NiMH/NiCD/Li-Fe/LiHV/Li-ion and anything from 1S to 6S with balancing leads.

I don't see any way to 'just dropping various battery packs' First of all, the balancing connections are separate, and secondly, the connectors for the battery packs are numerous. If you are making your own battery packs, you can cobble something together that allows a drop in style, but how will you do the balancing leads?

I understand what it is like to have an idea and now you can't see any other solution so I will not try anymore to convince you to re-think your approach. Just be very safe, have eye protection all the time, and do outside testing of course. Just remember testing isn't to prove your unique idea is correct, it's to try and break it but that takes a lot of time and money. In my software career, we sometimes took a full year of testing because a mistake could cause a worldwide economic catastrophe. The fact you didn't see that happen is because we never got it wrong.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@inq Didn't see your post while I was writing mine. I have a similar unit, and apparently, so does the OP. Why he wants to play with fire is beyond me, Lithium is nasty stuff, but he knows the danger, or at least I hope he does.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

I'm sorry I haven't been clear. Now I have hijacked this thread which I wanted to avoid. Someone please tell me if this discussion should move to a new thread with a more appropriate title.

You commented: "I don't see any way to 'just dropping various battery packs' First of all, the balancing connections are separate, and secondly, the connectors for the battery packs are numerous. If you are making your own battery packs, you can cobble something together that allows a drop in style, but how will you do the balancing leads?"

By "dropping various battery packs" I mean the normal way of attaching a tool battery to its proprietary charger--the battery pack contacts connect with the charger contacts by sliding or lowering the battery pack into some sort of recess. I maintain batteries for four brands of tools and each has its own style of charger connection. I can charge any of my tool battery packs on my B6 charger, and do, when I want to cut off the charge at, for example, 11V instead of the full charge level of 12.6V.

I'm trusting others who state LiIon cells will last significantly longer if stored at 3.6-3.7V rather than fully charged to 4.2V. I care because my battery packs sit around alot. I might use a tool every day for a week and then not use it for six months. Or I might use a tool sporatically for an average of one day a month. My string line trimmer has its battery drained completely once a week when the grass grows and then sits idle over the winter.

I also care because all my tools are old and I have already replaced the cells in their battery packs once or twice. Some started life with NiCad batteries which I replaced once with NIMH and later with LiIon. For these conversions I had to shoehorn BMS boards into the original battery pack casings and solder the guts from a wall wart charger for LiIon packs into the original charger housing.

Manufacturers choose cells for their tool batteries by compromising between cost, capacity, discharge rate, and the number of times a cell will recharge. Study of the battery cell datasheets demonstrates you cannot maximize all of these characteristics at the same time. But you can second guess the manufacturer and skew the compromise in a particular direction. In my case I choose higher cost cells with high discharge rates. It is amazing how much more force one can get from an existing tool by increasing the rate at which the current can flow from the battery cells. These days manufacturers do this too and sell higher cost premium battery packs along side their normal fare.

It is also worth buying your own cells when you need greater capacity. I built a new battery for my string line trimmer last fall. Instead of five cells 5S1P it uses fifteen 5S3P. I installed them in a knock off battery box that copies the fit to the tool and the charger--boxes that weren't available ten years ago. For $75 in parts I have a high drain, high capacity pack the manufacturer sells for $200. I'd like for it to last more than five seasons and a storage charge regime should help.

Every LiIon battery pack I've ever opened used a BMS board to balance the charge across the cells. So a tool battery charger does not provide the balance function. As I understand a BMS circuit drains charge from fully charged cells while the charger continues to provide current until all of the cells reach full charge. Otherwise the variations in internal resistance between cells would cause the higher resistance cells to be charged to lower and lower levels everytime the pack is recharged. This spells early death to the cells in a pack that start life with slightly higher internal resistance. Even despite BMS circuits tool battery packs usually become unusably weak because one or two cells have fallen below the minimum discharge voltage.

When I first got my B6 charger I thought it might do a better job of balancing cells. I opened a tool battery pack and soldered a set of balance wires onto the individual cells. The wires terminated in an HX-male plug that I attached to the corresponding HX-female receptacle on the B6. After half a dozen charge-discharge cycles and measurements across individual cells I concluded the BMS in that particular pack did just as good a job of balancing the cells as the B6. I know, that's one test of one BMS board and one set of cells, but it was enough for me. I suppose if I wanted to be extra careful and possibly discover a malfunctioning BMS I could open all my packs every other year and measure the individual cells, but I haven't gone that far.

So, in short, I don't generally make my own battery packs. Usually I just replace old cells with fresh ones. This does involve spot welding them together with new zinc strips and sometimes replacing the fish paper but it is not starting from scratch. For the NiCad conversions it also involves fitting a BMS and mechanically fixing different shaped cells in an existing plastic box. And in the one case where i did build my own pack I used a commercially available kit that included a box, a BMS and all the contacts. As for balancing, I trust the BMS boards to do their job.

I do not think I am foolhardy. I have gained some confidence from replacing rechargeable batteries for more than 25 years. I've changed them in shavers, electric toothbrushes, PDAs, phones, bicycle lights, SCSI and SATA Raid boards in servers, memory cache cards, and the list would probably go on if I kept thinking about it. Nevertheless, I am mindful that I do not do electrical work every day and need to constantly remind myself of the danger.

I learned about chemical violence as a youngster with a home chemistry lab that went way beyond what comes in a box. I would blow up paint cans after filling them with hydrogen. I made hand grenades by stuffing spent CO2 cartridges with saltpeter and sugar. I made a cannon from pipe that fired golf balls to terrorize squirrels. I once tossed a lump of pure sodium into a bucket of water. A few minor burns and close calls taught me early to respect the power that can be packed into a small package.

@cecil Sorry, I did misunderstand. I thought the batteries were RC-style with JST connectors. As a DIY guy and major renovator, I have NEVER had to replace batteries like you. I never even heard of this store at lower voltage until I started studying LiFePO4 for my solar setup. Why this crazy idea has gained so much traction is a mystery to me. Charge to 100% (BTW, I NEVER use voltage, too unreliable, I measure the charge via a shunt). If a battery is fully charged and then left, it will naturally slightly self-discharge. There is no need to speed up that process, although I am sure you can find many quotes to the contrary. It's the way of the world now and is about to get much worse with AI. I take my information from the guy who also guarantees the batteries last at least 8 years.

I doubt I can add anything to your vast experience, I have not had to face your challenges probably because I was just lucky and followed the manufacturer's recommendations, so I will unsubscribe from this topic. Good luck.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

As there were some questions regarding the existence LiFePo4 in 18650 format here's an update.

I ordered 4 1500 mAH cells from AliExpress and I received then within 3 weeks.

I payed €18 incl postage for 4 cells.

I did not test the capacity yet, but the voltage of the 4 cells is between 3.295 and 3.297 volt.

The cells weigh around 40 grams which seems about right.