The ESP32 Camera has a board that goes with it to ease the process of downloading programs etc, and it is known as "ESP32-CAM-MB".

It comes with a mini or is it the micro dont know... so many configurations to keep up with (pretty much the "standard sized small one") also has 2 push button switches to assist with the DLing.Well anyway, the board ( or the 2 I got from Amazon) seems have a design flaw or a part placement issue. The diode next to the main chip promptly made the pixies to become flatuant... the nasty smelling gas was released and the board ceased to live. Dont know if the diode is a reverse polarity protection or a ripple reducing function. When the USB plug made its way into the socket, and about several seconds passed it toasted itself. I checked the USBs voltage and it was sitting at 5.02VDC with .2 VDC ripple ( I luv my sillyscope). So thinking it was maybe a one of bad diode, I put the second one into service and the pixies farted again. OK... 2 in a row, the only thing I can assume now is that the board has some bad circuitry going on. The USB port checks out fine, the Cameras are fine, and I cant think of anything else that would cause it to pop as it did...

So, If anyone else experiences this issue or knows what happened, Id luv to hear from yall, do a follow up here...

Thanx,,, BunnyKiller

Hi @bunnykiller,

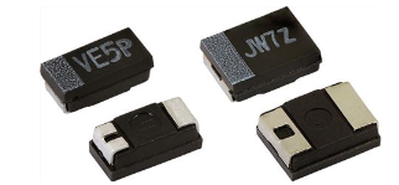

Random thought ... might your anti-social "diode"s actually have been (surface mount) polarised (aluminium electrolytic or (possibly but unlikely) tantalum) capacitors. Such capacitors can obviously be soldered in two ways .. the right way and the wrong way .. and have been characterised in the past as 'functioning' long enough to pass a 10 second production line test when soldered either way ... but failing in seconds to minutes when soldered in the wrong way in 'normal' usage.

Looking at photos on the web, I assume the 'main chip' you refer to is type CH340C. Data sheet for the CH340x family at https://www.mpja.com/download/35227cpdata.pdf shows 10 microFarad decoupling capacitor, in parallel with 0.1 microFarad ceramic capacitor, across the power input pins, which are 1 and 16 for the C type.

You can probably check to see if your defunct components are connected this way .. determining which way they soldered might be more tricky if they have self-destructed. Warranty could be an option if you don't want to risk fixing yourself.

Good luck.

@davee what gave me the idea that it was a diode was the color, black, with a line printed on it as most diodes have and a code of SL. When the "item" failed it developed a little extrusion of bubbly plastic near the end opposite of the printed white line. Most of the time when SMT caps fail they crack and crumble ( from what Ive experienced so far) and the few failed resistors Ive tried to replace turn black and powdery and usually come apart when removed from the board. This mystery part held together when removed. Im considering "repairing" this board but not knowing exactly what type of diode it is could very well destroy the mosfet and main chip... I was thinking of stuffing a very small standard diode to the weld pads and power it up and see what happens.. its not doing any good as it is now either, so who knows, maybe I will learn something from this pixie fart...

Hi @bunnykiller ,

Sorry, I have no idea what the code SL means. Components from the 'big name' companies often have high resolution printing, so that they often (not always) print logo, capacitance, voltage, tolerance, etc all on tiny package ... but (speculating) these may be from a smaller outfit, or even a 'relabelling' outfit that buys out of spec parts in bulk and relabels with a simple machine. Initially, I had thought aluminium was more likely than tantalum, because it is usually cheaper, but supply chain games might reverse that cost preference.

I suspect the dead capacitors you found crumbled in the past were ceramics, which are not polarised. And neither are resistors, which usually get overheated and turn into burnt toast.

I agree, diodes can look like that part, but what job would a diode be needed for? Sometimes, a diode is put as protection for polarity reversal in the incoming power line, but this board is powered by USB which is unlikely to suffer this problem. Checking how this component is wired into the circuit is the only way.

I have checked that my first thoughts were plausible. Polarised capacitors with that package style are available. I found a few aluminium electrolytics (although most are cylindrical tin can), but more commonly tantalum.

An example of a component with similar appearance to photo of your MB I saw on the web, except for the printing, from a Vishay data sheet https://www.mouser.co.uk/datasheet/2/427/tmcu-1763538.pdf

Wikipedia has some notes of interest .. https://en.wikipedia.org/wiki/Tantalum_capacitor

All tantalum capacitors are polarized components, with distinctly marked positive or negative terminals. When subjected to reversed polarity (even briefly), the capacitor depolarizes and the dielectric oxide layer breaks down, which can cause it to fail even when later operated with correct polarity. If the failure is a short circuit (the most common occurrence), and current is not limited to a safe value, catastrophic thermal runaway may occur. This failure can even result in the capacitor forcefully ejecting its burning core.

A particular cause of confusion is that on surface mount tantalum capacitors the positive terminal is marked with a bar. Whereas on aluminium surface mount capacitors it is the negative terminal that is so marked.

Whilst I am only looking at photos and considering the data sheet I referenced in my 1st reply, I can see why there might be 10 microFarad 6V capacitor but not a diode. I still think a capacitor is top of the suspect list.

I suggest you try to check the circuit of your board, comparing to the CH340x data sheet circuits. If "SL" is directly connected to the 5V and ground supplies the CH340C, then a decoupling capacitor seems much more likely than a diode.

If you want to try a capacitor, aluminium electrolytic should be fine. Make sure you get the polarity correct .. remove the remains of "SL", power up the board and measure 5V to check, before soldering in the new part. From the data sheet, I would suggest about 10 microFarad or more (say up to 50uF), 6V or more voltage rating.

Of course, this is all speculation ... I take no responsibility for any errors, etc.!!

Good luck.

The ESP32 Camera has a board that goes with it to ease the process of downloading programs etc, and it is known as "ESP32-CAM-MB".

@bunnykiller - I also have purchased a couple of ESP32-CAM modules with that separate small board. Mine have not farted, exploded or otherwise misbehaved. I've found them quite convenient, compared to last year when I had just a ESP32-CAM I had to hook up via an FTDI, and remember to ground GPIO0 each time. Oh, and as Bill mentions, it should be programmed at 3.3V but will probably run better at 5V, due to peak power required by WiFi. So testing with this little sister-board is quite convenient, and just needs USB.

The couple I got this year came with the following description and link:

I do find it a little bit of a gamble ordering from Aliexpress, but I like it well enough. I just don't always understand what it is I'm ordering.

Good luck!

In theory, theory and practice are the same.

In practice, they're different.

Well its been quite a while and found my answer, the part that poofed was a diode and I replaced it with a 4007 and it lives... Loaded up the code and got it working. Altho, there are 3 camera boards that dont accept code and seem to get warmer than the one that does work. Is there anything that can be done with the "spare" cameras I now have in my possession. Drives me nuts to see good stuff not being used...

@bunnykiller Very strange, I have more than a dozen MB boards and that or more camera boards. I have yet to lose a single board. One thing I have NOT done, though is to replace 3.3V with 5V. That will release the smoke.

Some of my MB boards have the 'better' USB chip so don't even need to press the BOOT button to do an upload. I also ONLY power the boards with USB so there is never an issue with mistaking 3.3V and 5V.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@jbo When you say

it should be programmed at 3.3V but will probably run better at 5V, due to peak power required by WiFi

you need to be clear for the benefit of newer members that only refers to the FTDI method, the actual board uses USB power which gets stepped down to 3.3V from the USB 5V.

Changing from 3.3V to 5V will normally kill the board unless it is a 5V board and was being underpowered at 3.3V.

Changing voltage will NOT improve WiFi, it might kill it or it may not work at all but circuits are in the main designed to run at a specific voltage range.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

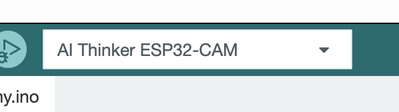

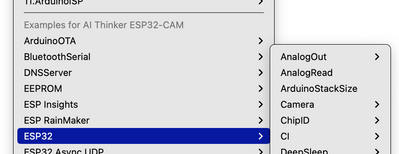

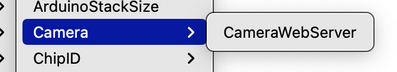

@bunnykiller Load up a simple BLINK sketch to see if that works. If it does, then load the sample webserver camera sketch and see if that works. I am including pics to show which BOARD, and which example as there are other camera sketches that might work but the sample is the better board health test.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@jbo Not sure why you think it's a gamble to order from AliExpress. I order a lot from there and I have had a few shipments disappear but AliExpress covers any loss even if the individual store does not. Simply follow the procedure within the very generous time frames allowed. It is super easy.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@zander Thanks for that note, especially on clarity of reference to various operating modes. Yes, I did program mine, via FTDI, with the 3.3V jumper.

My ESP32-CAM did not have any USB connector of its own.

The 5V reference I made was from @bill in Build an ESP32CAM Robot Car. The spot I linked was just after the start of the section on power supply, as in the two power supplies for the car with batteries. As best as I can transcribe it, the exact quote is:

Now the ESP32-CAM module is a 3.3V module, but it has both 3.3 and 5V power inputs because it has internal voltage regulators. And many people have found it is more stable when you use the 5V input. So that's what we're going to be using to power our ESP32-CAM. As for the motor supply, . . . .

So, I think I misremembered "stable" and substituted "better WiFi" in my comment; apologies. Speaking more generally, I have spent a huge amount of time researching whether to use 3.3 vs 5V, simply because I'm a relative newbie myself. I see a lot of opinions, find it frustrating, and so I gladly just plug in USB whenever the module and/or the project allows. For what it's worth, I give the highest rating to articles and comments I see here on DBWS. Best, John

In theory, theory and practice are the same.

In practice, they're different.

@zander Hey Ron, Ah, I don't remember the exact context of my remark, but I should set the record straight. As far as orders received, my experience is pretty much like yours; it's great.

What I meant, specifically, is that for things more complicated than nuts and bolts, say, electronic modules, I find it hard to read the title of the listing, the description, and determine what I'm actually buying. This is mostly on me, and none of these items are so costly it's much of a gamble; more like an educational experience. 😉 Once I've received the order, compared to my notes, I have a much better understanding for the next order. As a random example,

is the kind of listing it would take me a while to parse, making sure I clicked the little tabs to choose which "color" of microcontroller I wanted, before I decided it was what I was trying to buy. Not saying the product is bad, just that I, personally, found it somewhat confusing, and have to go slowly to avoid getting the wrong thing. Four years ago I would have said I'd just rather go to Amazon and pay a little more, but in the last few years I've noticed a big increase in the number of amazon.com listings with titles very similar to that above. Apart from the title, some of the detailed descriptions are good, some are pretty poor. YMMV. Long story short, I just pays my money, takes my chances. 😀

In theory, theory and practice are the same.

In practice, they're different.

@jbo Since the 5V supply from whatever source goes to a Voltage Regulator and gets converted to 3.3V in theory, it makes no difference. You and others might be seeing some weakness in available 3.3V supplies (batteries?) that causes the apparent differences. My 3.3V supply is fed by my 5V supply using the same VR the esp32 uses. That is why I don't see the difference, but also, like you, if USB is a possibility after uploading, that is almost always what I use. I have several ES32s running inside various furniture and walls with a 12V to 6.5-7 V LM2596 buck converter that feeds a Voltage regulator that takes it to 5V and then is connected to a USB male plug. 12V is readily available in the auto, marine, and RV industries, so I use that as my DC supply and then step it down using both VRs and buck converters.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

@jbo It sounds like we have the same experience with Ali. Sometimes I mark several similar-sounding items for my wishlist as a first pass. Then I come back and scroll down each page as detailed info is often further down. Other than ordering esps with a different number of pins than those I already have, none of them have failed to work. If you get very deep into it, then the amount of flash, ram etc, may be critical and then a deeper reading of the spec will be needed. With the PICOW now on the market, I wonder if I will be buying any more esp chips since the PICOW is cheaper and less prone to 'clone' rips-offs.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.