I'm sure there is already a topic on this subject. Unfortunately, the search engine on the forum does not appear to be working. On the Internet at large, too much information, but not what I want.

RC Airplanes are my current hobby. I want to interface the plane side receiver with an ESP8266 for telemetry and control functionality. The receiver's protocol uses half duplex Serial communications at 115200 baud. It's at 5V and the ESP8266 is at 3.3V. To keep the receiver from blowing out the 3.3V pin, I need to change that voltage. At the moment, I'm using a voltage divider.

- Why would I use logic level shifter instead? They seem like they have limitations and are more expensive. A voltage divider - two resistors. What am I missing?

- Internet says there are two kinds shifters. One posting said that "cheap" logic level shifters actually use a voltage divider for the 5 to 3.3V direction and some logic chip for the 3.3V to 5V direction. That... "good ones" use something else for the 5-3.3 direction.

- Why are these better?

- What am I looking for to make sure I'm getting these better ones?

- Do I need to use 3.3 to 5V shifting for servos. I've done many projects with servos on the ESP8266. I've always just used the pin to supply the PWM. Should I be using a shifter since servos are typically 5V devices?

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Hi @inq,

These comments are based purely on what I grab from the web .. not experience ... treat with as much salt as you think fit!!

-------

The first point is to note that (I suspect) interfaces of units like RC radios and servos that you can buy, are rarely properly specified with 'hard numbers'.

Saying an item has "5V logic input" tells you nothing almost about the exact voltage ranges it will regard as '0' and '1', nor the impedances of that circuit. Now, if you drive it with a circuit that produces nice 'square' logic data, with low and high levels at low impedance very close to 0 Volts and 5V, then there is a high chance it will work without a problem.

However, if your driving circuit is an 'economy' version, perhaps having an impedance of a few hundred Ohms or more due to resistors, etc. low voltage level is about 0.5V, high voltage about 3V, slow transitions between high and low logic levels, will the input circuit still work reliably?

The answer degenerates to a 'maybe, maybe not'.

--------------------------

Why would I use logic level shifter instead? They seem like they have limitations and are more expensive. A voltage divider - two resistors. What am I missing?

Obviously this can only work properly for 5V output driving 3.3V input, not the other way round.

Your voltage divider resistors are in parallel with the components of the input circuit of the receiving unit, which will alter the output. Obviously, you can modify the choice of resistor values to compensate, but you might need an oscilloscope to see check the waveforms, etc. Otherwise, you could end in 'marginal' situation, such when the signals are just meeting the requirements when the battery voltage is good, but starts failing as the voltage falls with use.

-----------------------

Internet says there are two kinds shifters. One posting said that "cheap" logic level shifters actually use a voltage divider for the 5 to 3.3V direction and some logic chip for the 3.3V to 5V direction. That... "good ones" use something else for the 5-3.3 direction.

-

Why are these better?

-

What am I looking for to make sure I'm getting these better ones?

I haven't looked into the finer details, but there is a circuit based on 1 MOSFET and two resistors, which does its best to overcome to 'do the job properly'. The earliest reference I know of, comes from a Philips application note for joining two I2C networks together, one 3.3V the other 5V, which requires the same 'joiner' circuit to work in both directions. Sparkfun have kindly documented the circuit, including a reference to the original Philips Application circuit.

https://learn.sparkfun.com/tutorials/bi-directional-logic-level-converter-hookup-guide

Sparkfun also sell a small board with 4 such interfaces > https://learn.sparkfun.com/tutorials/bi-directional-logic-level-converter-hookup-guide I think it is fairly easy to spot the pattern of two resistors and 1 FET per 'channel', typically having 4 'channels' on a board. I haven't noticed any significant variations with "other chips" or "just resistors". You could even 'build your own', for a few cents worth of components. The most tricky bit is that the obvious FETs to use tend to be small, so you probably need a PCB with the right footprint. You can buy the 'prototype' boards, but they will cost as more than the 'look-alike' converter boards, with components already fitted. I can think of alternative circuits, but they are probably all more complex than the 'Philips' design, just discussed. These boards are intended for logic voltage conversion in the range between about 1.8V and 5V. They assume short wirelengths, minimal electrical noise, etc. More robust solutions are required in say a noisy industrial motor situation. -------------- Do I need to use 3.3 to 5V shifting for servos. I've done many projects with servos on the ESP8266. I've always just used the pin to supply the PWM. Should I be using a shifter since servos are typically 5V devices? Basically a repeat of above. I have yet to see a proper electrical specification for the interface of a servo .. e.g. SG90 just seemed to say 4.8V to 6.0V for both logic and supply voltages. The implicit assumption being that supply and 'high' logic level should match. So should you drive it with a 3.3V ESP8266? ... Definitely, advised as Don't do it! Will it work if I ignore the advice? ... Quite possibly! But it is probably stressing the ESP8266 pin output circuit and failing to provide the 'full' voltage level expected by the servo. If it works, it is probably a combination of the ESD diodes in the ESP8266 pulling excess current from the servo input to reduce the voltage, and the 'high' level voltage at the servo input still being high enough to be treated as '1'. Logic circuits include margins to allow them to reject noise and signal corruption --- you may using some or all of that margin to overcome a 'poor' design decision. -------------- In case you are looking for a 'belt and braces' approach to interfacing, there is an perennial fear of 'CMOS latch up' to be aware of. This is unlikely to be a major concern, but it is better to at least know it exists. Note this problem exists whether or not a voltage level conversion is required, but it so happens the 'Philips' converter has protection in one direction, and they also described how to modify the circuit for the bidirectional case. It should be considered whenever a system has more than one power supply source or if one source has more than one switch with each switch feeding a different part of a circuit. Imagine you have two circuits ... with the following description Ideally, both would be powered up at the same time, but if (say) the sensor was powered up first, and the output went to the high voltage level, then the ESP8286 input connected to the output would receive the 'high' voltage input of (say) 3V, whilst its power lines were still at 0V. All CMOS inputs have ESD diodes, which in this circumstance can result in the whole (ESP8266) chip being partially powered. It can also result in the intrinsic thyristor construction associated with silicon CMOS latching on. In the worst case, this can damage the (ESP8266) chip, particularly if as the ESD diodes are not designed to handle continuus current flow, but more commonly it might be in a state that prevents it working properly if it is powered up whilst the chip is in this latch up state, but 'recovers' if the whole system is power cycled correctly. The moral of this tale is described in the Philip application note, namely to use two FETS in a 'back to back' arrangement when building their voltage converter ciruit. However, I haven't seen any such boards on the usual marketplaces. --------- Best wishes, Dave

@Inq One small consideration is a voltage regulator will protect you from surges while a voltage divider will still pass along any surge albeit at a somewhat reduced level.

First computer 1959. Retired from my own computer company 2004.

Hardware - Expert in 1401, and 360, fairly knowledge in PC plus numerous MPU's and MCU's

Major Languages - Machine language, 360 Macro Assembler, Intel Assembler, PL/I and PL1, Pascal, Basic, C plus numerous job control and scripting languages.

Sure you can learn to be a programmer, it will take the same amount of time for me to learn to be a Doctor.

Hi @inq, Just to brush you up on the basics of a RVD ( resistive voltage divider), the reasons why RVD's are not recommended to use on circuits with appreciable current loads, is because as current increases through the load, that current also increases the current through the RVD's R1 resistor, which will increase the voltage drop across R1, and decrease it across the R2.. see the examples on the drawing furnished with this post.. I think you'll see why RVD's are not recommended with circuits with any appreciable currents flowing thru the load.

As for voltage level shifters, it is always wise to use voltages that are complimentary to the required voltages of the circuit you are working with. That's the reason why we have voltage level shifters. As for whether one is a good or bad design, that depends on what you are using it for... most hobby project are not using high quality devices, that's why they're so cheap to buy..

This is an excerpt from https://electronics.stackexchange.com/questions/42727/what-is-the-difference-between-level-shifter-voltage-regulator-and-dc-dc-conver

"A level shifter is usually a part that converts digital signals from one logic standard to another. It might also be called a translator. For example, the MC14504B converts TTL logic signals to CMOS levels, and a MC10H607 converts PECL signals to TTL. A level shifter isn't meant to provide power, it can only source as much current as its target logic levels require.

The terms voltage regulator and dc-dc converter are somewhat overlapping. Classic linear regulators are almost always called regulators. Linear regulators can only be used to produce a lower voltage from a higher one. Switching supply circuits might be called regulators or dc-dc converters. (Purists might claim that the regulator is just one part of a dc-dc converter circuit. That is the regulator is what provides the feedback control, whereas the dc-dc converter is a complete circuit including external magnetics, switching transistors or diodes, etc.) Switching supply circuits include different types that are able to produce either lower or higher voltages from an input voltage.

To produce 2.5 V from 5 V, you can use either a linear regulator or a "buck" switching converter."

I hope this helps you understand the differences..

regards,

LouisR

LouisR

As usual a very well thought out answer to answer the questions as well as to even think ahead at what I might run into and at a level that is enough to satisfy my wanting to understand, yet not overload me. 😉 Thanks @davee.

Definitely good references on the Sparkfun links. I'll keep those.

So should you drive it with a 3.3V ESP8266? ... Definitely, advised as Don't do it!

But it is probably stressing the ESP8266 pin output circuit and failing to provide the 'full' voltage level expected by the servo. If it works, it is probably a combination of the ESD diodes in the ESP8266 pulling excess current from the servo input to reduce the voltage, and the 'high' level voltage at the servo input still being high enough to be treated as '1'. Logic circuits include margins to allow them to reject noise and signal corruption --- you may using some or all of that margin to overcome a 'poor' design decision.

I'm not sure I'm getting all of this in the context of the logic portion... I'm thinking I was just not being thorough in my description, but want to double check. I do have the power going to the servo coming from a 5V bus so it is not drawing its motor current via ESP8266 pins. I was just meaning, I was using the 3.3V logic pin to supply the PWM signal to the logic wire of the servo. Were you thinking I was also drawing power via ESP8266 pins or do I really need to route the logic pin through a shifter also before going to the servo?

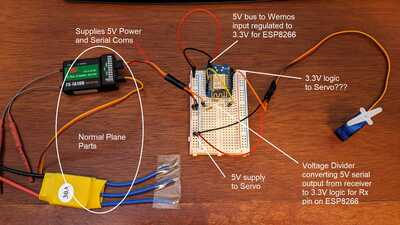

Here's the basics so far in my project...

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

"A level shifter is usually a part that converts digital signals from one logic standard to another. It might also be called a translator.

With my picture above, I think I'm using it just to convert the serial logic line... not powering anything significant via the voltage divider.

All in all, you all have convinced me, that even it this is working at the moment, it might be blind, dumb luck! 🤣

I've order some 4x shifters as @davee pointed out... which works out nice as I need one for the serial communications and I can use the other three to convert PWM logic to three servos... just what I need... ailerons, rudder and elevator.

Thanks guys!

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

With my picture above, I think I'm using it just to convert the serial logic line... not powering anything significant via the voltage divider

Yes I think you are correct in your assumptions.

Having done some online reading it appears that 3.3v is sufficient to act as an ON signal for a 5 volt logic gate and some 3.3v logic gates can handle a 5v input which would save all those resistors if a lot of pins were involved. I guess you just have to read the specs for whatever device you are using.

Apparently for the esp the I/O pins are not 5V-tolerant!

Hi @Inq and @robotbuilder,

re:

I do have the power going to the servo coming from a 5V bus so it is not drawing its motor current via ESP8266 pins. I was just meaning, I was using the 3.3V logic pin to supply the PWM signal to the logic wire of the servo.

Yes, that was the arrangement I was assuming. And yes, in the absence of other information, my recommendation is to use a level shifter when driving a 5V servo from a ES8266 PWM.

As I mentioned, I haven't seen a 'proper' inteface spec for any servo, and there is no reason to be sure that any two different servo models, or even two different 'clones' of the same type, will have the same characteristics and behave in the same way, especially when if you try providing a 'non standard' drive arrangement.

However, all of the information I could see, said the PWM drive voltage should be nominally the same as DC power voltage. And in the case of the SG90, that voltage should be in the range 4.8V to 6.0V, which clearly excludes 3.3V logic....

---------

A resistive divider obviously depends upon the ratio of the values of the resistors, so how do you pick absolute values?

If you are designing resistive dividers for a data link, then first be sure that your data outout has sufficient drive to cope with the resistive load .. this will encourage you pick higher value resistors to reduce the loading...

But also, you need to be aware that the receiver input will have some caapacitance, which will be in parallel with the lower resistor in your potential divider, so that it will attenuate and slow down the transition edges. This will encourage you to pick lower value resistors to reduce the effect of the capacitance...

Hence, the need to find the Goldilock's choice.

Now for your radio control, I guess the data rates are low, so these issues are much less likely to be a problem, but you should be aware of them .. your next project could be different.

--------

Having done some online reading it appears that 3.3v is sufficient to act as an ON signal for a 5 volt logic gate and some 3.3v logic gates can handle a 5v input which would save all those resistors if a lot of pins were involved. I guess you just have to read the specs for whatever device you are using.

I have no problem with the last sentence, but the first sentence is more of a 'sometimes ...'

Logic gate "families" have a longer history than integrated circuits ... to the extent that even I have never met some of the early generations ... so my comments only go back to Texas Instruments 74xx series, which came with its ubiquitous orange data book, that for years was as essential part of the bench tools, as a pair of wirecutters.

The first member of the family was the quad 2 input NAND, the 7400

which was accompanied by the 74S00,

then the 74LS00, 74HC00, 74HCT00, 74AHCT

and no doubt lots of others. (This is ignoring the CD4000 series, PECL and so on.)

Each of these (at least the ones I have encountered) have different transition voltages, and of course some of the latter ones will work on a wide range of supply voltages, so that the transition voltages also depend on the supply voltage.

Plus, if you ever come across the early ones which are 'TTL' (transistor-transistor-logic), as against CMOS, you wil find the outputs are 'driven' towards 0V by a transistor when outputting a 'low', but only have a resistor to pull them towards the supply voltage when outputting a 'high'. Hence the current drive capability is very poor in the 'high' direction, which can present more issues.

So yes, if you interconnecting two devices with fully specified characteristics, then some degree of mix and match is indeed possible, but be prepared to read the data sheets several times, comparing all the voltages, currents, etc. if you want to be sure it is good match. Or perhaps you are one of those people who are always lucky.

Best wishes, Dave

Yes, that was the arrangement I was assuming. And yes, in the absence of other information, my recommendation is to use a level shifter when driving a 5V servo from a ES8266 PWM.

Most of the time it has worked fine in past projects. Sometimes it'll have a little jitter on an random servo when code is saying to be still. I always assumed it was just needing a big storage capacitor across the power. Maybe it was just that servo was at that point of not quite enough voltage (at the 3.3V coming from the ESP8266) where it was undecided being on/off.

I was trying to keep the part count and/or soldering effort down. There might be product opportunities here in small quantities and I can't see myself being a line worker. 😆

Now for your radio control, I guess the data rates are low,

115,200 b/s.

I'm assuming most of the warnings you gave go away if I use the shifters. I have the ones you suggested coming tomorrow (so the tracking says).

The radio transmitter/receiver being used is a commodity set that costs all of $55 for 10 channels and programmable mixing, and telemetry. Sure isn't like when I was doing this back in the '80's. Back then two servos would set you back $50.

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

@inq , As @davee has suggested, use a level shifter. you can use a ESp8266 to drive a level shifter from3,3v to 5V for the proper signal to the servo..this would also create isolation from the higher Dc voltages used to operate the servo's and any other circuits you have using voltages above the ESP8266 3.3v.

Good luck with your project, and lets us know how it all shakes out!..

regards,

LouisR

LouisR

Good luck with your project, and lets us know how it all shakes out!..

regards,

LouisR

Sure will. Here is where it stands now. I want to do two things with the same ESP8266. I want to do flight control and telemetry.

Flight Control

The flight control should be pretty much like a self balancing robot, except in all three axis. I'll use a MPU-6050 for gathering the gyro and accelerometer data and it will take the inputs from the transmitter, but massage the outputs to the three servos to compensate for aircraft attitude. It'll also have gain controls to say allow for more "active" flying versus just "cruising". Here shows the first experiment that led to this thread. Other thoughts include:

- Adding a record feature that would allow to do a choregraphed flight and being able to play it back and it fly the plane through the same "show".

- Using ultrasonic sensor to detect the ground coming up and have it automatically land the plane.

- Using a GPS unit and do positional things like way-points and orbiting a location.

... and here is a little video that has it working. One servo is connected directly to the receiver while the other is using the same channel's input and driving the second servo... thus showing any latency. Doesn't appear to be any and this should easily handle all three MPU controlled servos once I get the shifters installed.

Telemetry

The second thing I'm exploring is telemetry.

- The NUMBER 1 most important thing that started this whole mess was monitoring the LiPo battery voltage. Right now the transmitter does receive the receiver voltage. But this is next to worthless since the Electronic Speed Control (ESC) sends a regulated 5V to the receiver no matter what the LiPo battery voltage is - 3S being 10.5 to 12.6 volts during the flight. I want to monitor that voltage using the things @inst-tech helped me out with ages ago on the single A0 line of the ESP8266. Right now all the old-timers at the field, they simply set a timer and land when it beeps. Me, I want to be able to blow holes in the sky and it say "land now fool" or if I'm cruising at cracked throttle, I might stay up for an hour.

- A dirt cheap addition was adding a BMP280 pressure sensor. When it MPU boots ups I can get the altitude of the plane. While flying I can have it send down the altitude AGL. The rig above shows with the BMP280 reading and sending telemetry data at 25 Hz.

- A second BMP280 configured in a pitot tube and using the static one in #2 can give the airspeed of the plane. Here is the low-speed test vehicle with the pitot tube out front in a simulated jet radome. 🤣

At them moment, all the telemetry data can easily be shipped down via WiFi of the ESP8266. In the video above, it's not real clear, but you can see all the values in the web pages on the computer screen. On the left in tabular form and on the right, showing the ailerons/elevator/throttle/rudder positions in histogram form. It'll be easy enough to display in fancy GUI webpages like an airplane dashboard. Some of the experimenting with that is what kind of range I can get with the WiFi. Will explore using secondary antennas on the ESP8266. I've seen articles showing kilometer ranges with optimum conditions with the ESP8266. Considering that its always above me and clear line of site, I should get optimum conditions all the time.

Secondly, this brand of transmitter/receiver also supports up to three displayed values to be shown on the transmitter... say LiPo voltage #1, Altitude #2 and Speed #3. That was what lead to this thread also. I knew I needed to send data from the 3.3V serial of the ESP8266 to the 5V receiver so it can send it back to the transmitter.

That's about it for the current status. I'm also learning to fly and have crashed about as many planes as I have burned up ESP8266's. 🤣

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Hi Inq,

Maybe it was just that servo was at that point of not quite enough voltage (at the 3.3V coming from the ESP8266) where it was undecided being on/off.

Symptoms are consistent with what I would expect by driving it with a nominal 3.3V waveform when it was expecting a nominal 5V waveform, but obviously inadequate power supply, including poor decoupling, might also produce similar problems. Fixing this most obvious deficiency is a good start.

115,200 b/s.

Yes, that was what I thought it was ... and easily qualifies as 'slow'.

My comments about other situations had data rates from apparently 'everyday, cheap' data communications like USB, which started down in the 1MHz region, but is now heading towards 10 GHz. Similarly, wired Ethernet and maybe others. The widespread usage and low cost suggests it is easy as the low frequency stuff, but the physics indicates otherwise.

I'm assuming most of the warnings you gave go away if I use the shifters.

The cynic in me sees it to be more like betting odds ... not that I bet on horses or anything similar ...

If there are three horses in a race with a fair chance of winning, and the rest of field are outsiders, then using competent level shifters just eliminated one, or maybe two of likely contenders, leaving you with a much better chance of winning.

The level shifters only consist of two resistors and one transistor per 'channel', so even a 'low tech' manufacturing facility should be able to make them with a good success rate, providing they make a reasonable effort.

So I would regard level shifters as probably the best approach to that problem, but don't forget that other issues, like poor power wiring design, can still thwart you.

I was trying to keep the part count and/or soldering effort down.

Understandable, especially as you mention 'production quantities'.

It is a bit tricky for me to visualise the full picture, but once you have prototyped your system, have you considered whether a PCB would make life easier? Obviously if level shifting is the only thing to do, then with just 1 servo, it is not relevant, but if the 'full system' has other bits and pieces, it might be viable.

PCBs are generally easier to assemble, even on a personal 'production' basis, once you have everything in place. For example you might build our own 'level shifters' as part of the board, and use preassembled wires to plug and go. Alternately, you might go for a daugterboard approach, with the level shifter board slotting in and ust soldeing the pins.

I haven't used the facilities of the likes of PCBway and so on, but clearly they are trying to attract even small quantity orders. They seem to do both blank PCBs and also component assembly.

Others on the forum can probably provide more objective comments .. I am just saying have a think and a look.

-

Sorry no easy answers, but hopefully a useful suggestion or two. Best wishes, Dave

-----------

PS I just skimmed the article you posted whilst I was writing this .. Looks pretty ambitious, but based on your robots, I am sure it will be successful.

It sounds like it will have some kind of auto-pilot facility. Is that correct?

I note you are pushing the WiFi range ... has your aircraft got a 'homing' strategy if the WiFi signal disappears .. and are you monitoring the signal strength (both ways), so you can take appropriate action when it is getting low?

I just hope it doesn't get mistaken for a stray balloon. 😉

Dave

@inq ...Sounds like fun!..I use to fly many years ago .( when I was in my forties) Cessna 172 is what I trained on, because my buddy had one...heheh..I've never tried RC flying though..Too old now, at 76, the old eyes and dept perception aren't good anymore. Sounds like your on your way now to getting your project realized.

If we can help you with any of the technical, just hoot...

regards,

LouisR

LouisR

Yes, that was what I thought it was ... and easily qualifies as 'slow'.

Aren't we all a little slower these days? I sure am. 😋

The cynic in me sees it to be more like betting odds ... not that I bet on horses or anything similar ...

Yes, you have always been very good with the caveats... like you think I might be a lawyer that's going to sue you for burning up a pin on my $3 MPU. You're safe with me man! I'll always assume I fried it! Statistics don't lie. 🤣

It is a bit tricky for me to visualise the full picture, but once you have prototyped your system, have you considered whether a PCB would make life easier? Obviously if level shifting is the only thing to do, then with just 1 servo, it is not relevant, but if the 'full system' has other bits and pieces, it might be viable.

I think that is not really in my future. I had a business... and it would have been great if it weren't for the customers. Actually in that business where the product ran in the 5 and 6 and 7 figures, the customers were really great. I'm an engineer. I'll be the first one to explain what are the deficiencies of my product and I really don't want to deal with customers that won't read the instructions or are not smart enough to keep their tongue out of a light socket. I'm old and crotchety that way. 🙄

Although... I am interested more from what are the capabilities. I've seen the ads of making circuit boards and even populating them. I've never tried one. Any yes, if they could fully populate with the ESP8266 and just have the plain connectors for connecting servos, I could easily burn the software and ship. But... in this airplane hobby, people that make plane kits are in the tens... not the thousands. I really think its not a money maker and certainly not enough to make me quit my day job - called retirement and doing whatever I want!

It sounds like it will have some kind of auto-pilot facility. Is that correct?

I note you are pushing the WiFi range ... has your aircraft got a 'homing' strategy if the WiFi signal disappears .. and are you monitoring the signal strength (both ways), so you can take appropriate action when it is getting low?

I just hope it doesn't get mistaken for a stray balloon.

As said above... I really think this is only a self imposed challenge. Legally, you can't go out of visual range and the remote control works out to what my vision can handle. As far as the auto-pilot... again... its more of "can I do it" not that I'd use it even it I could make it work. At the very most, I'd like to make a sailplane that can just soar directly above the airfield and just let it catch thermals and see how long it can stay up. Being easily board... I'd rather something handle the orbiting duties.

In all those expectations the WiFi is only for sending telemetry down. I wouldn't rely on it for taking commands via WiFi.

VBR,

Inq

3 lines of code = InqPortal = Complete IoT, App, Web Server w/ GUI Admin Client, WiFi Manager, Drag & Drop File Manager, OTA, Performance Metrics, Web Socket Comms, Easy App API, All running on ESP8266...

Even usable on ESP-01S - Quickest Start Guide

Hi @inq,

Thanks for your reply.

I know my replies sometimes sound like I'm a failed, frustrated lawyer, and when I mention words like safety, then there is a sense of not wanting to be responsible for someone being injured, regardless of whether or not they are in a position to sue me.

However, in other cases, e.g. in answer to your query about whether level shifters will solve your problems, it is more that I am trying to explain that the action should solve some problems, but other problems may show similar symptoms, and even a similar prognosis, but requires a different antidote. I am hoping that if you are made aware of the other possibilities, then you can make an appropriate diagnosis or take appropriate precautions.

--------

I wasn't expecting you set up a 'commercial' production line, but as part of my research past, there have been occasions that it is necessary for the small project group (maybe 1-4 persons) to make half a dozen boards to the same design to make a 'demonstrator'. In such research groups, the same people typically do everything from designing, populating the PCBs to writing the software and making their own coffee. I thought this might be roughly comparable.

The PCB suggestion might be a complete red herring. But note I wasn't thinking of laying out ESP8286 modules, that are readily available for a few dollars, etc., but instead, maybe providing them with a nice comfortable motherboard to be fitted to ... or perhaps to provide a kind of socket board that they could plug into for distribution of power signals, etc. And if it was easier to build into the 'motherboard, a few level shifters or other cases where the board only contains a handful of components, then why not? Actually, weight and volume might be a reason, but that is just another engineering compromise to take into account.

Without seeing and playing with a 'full prototype' system, my imagination doesn't run to foreseeing the best approach .. and even if I had such a system, I know from past experience, people like those typically employed as mechanical engineers would do a vastly better job. So I was just offering it to you as a 'technology' that you might like to consider.

In summary, look to see if there are any 'messy' or 'labour intensive' bits that would benefit from a PCB.

--------

The auto-pilot reference was from a combination of references to GPS, orbiting, extending range of WiFi to kilometre, auto-land (though I think that is traditionally a separate system from auto-pilot in commmercial aircraft) and so on. I realised you had the usual joystick RC, so I wondered how these other references would relate.

Only me being curious of course ... good job I am not a cat ... the proverb suggests curious cats have a poor prognosis!

Best wishes, Dave