This easy-to-build Developers Module simplifies working with the ESP32-CAM and also provides a useful portable power supply for all your experiments.

Article with schematics on the website: https://dbot.ws/esp32mod

Today I’m building a project, an ESP32-CAM Developers Module. This handy contraption allows me to easily work with and program an ESP32-CAM module, without all the tangle of wires usually involved. It also provides a portable power supply that allows me to use the ESP32-CAM just about anywhere, and it even eliminates the dreaded “Blackout” condition messages!

I actually built this while filming another ESP32-CAM video, which you’ll be seeing soon. I love the inexpensive ESP32-CAM module, but experimenting with it presents a number of difficulties:

- The Reset switch is on the BOTTOM of the module, meaning you have no access to it on a solderless breadboard. And you need to have access to it.

- Even if you do get it onto a breadboard it eats up a lot of the pins. There is only space left for one connection to each module pin.

- You need to ground the GPIO IO0 pin when programming the module.

- Speaking of programming, you need an external FTDI adapter to program the module, or to use the serial monitor.

- If you don’t have enough current to get the radio started for Bluetooth or WiFi you’ll receive a “Brownout” error message. This is not unique to the “CAM” module, it’s an issue with most ESP32 modules.

- If you add an external antenna it becomes even more awkward to experiment with this module.

I ended up building this little project, which I’m presenting to you as a useful way of working with the ESP32-CAM.

Here is the Table of Contents for today's video:

00:00 - Introduction

03:48 - ESP32-CAM Prototyping Issues

06:40 - Development Module Features

13:51 - Module Parts Required

18:50 - Module Schematic

24:43 - Module Construction

30:50 - Building the Power Supply Base

37:58 - Testing the Power Supply

40:13 - Testing the Developers Module

Even if you don’t build this exact project you can still use the same concept for other microcontrollers that you work with frequently. Or you can make a better one with a bigger breadboard and more LEDs and pushbuttons.

And the power supply would be a useful project in its own right, it is both battery and AC adapter powered and it provides 3.3 and 5 volts in a very comp[act and easy-to-build unit.

"Never trust a computer you can’t throw out a window." — Steve Wozniak

I always enjoy all the great videos and ideas Bill. But I have a question. I was looking at the AMS1117 Module's that was used in this project. Most of the 3.3V versions that I can find specifies Input voltage of 4.5V to 7V. Is this not a problem when using a 9V battery or am I just not finding the correct module?

Hi @darkar,

I just did a quick Google ... the data sheet I found for the AMS1117 by Advanced monlithic.com at http://www.advanced-monolithic.com/pdf/ds1117.pdf

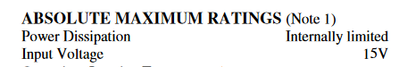

shows an absolute max rating of

suggesting a 9V battery would be fine on this point.

Of course, there are many 'clone' versions of the chip on the market, and they might have other ratings.

BUT There are at least two other factors to bear in mind:

- If you are looking at a small pcb module, this will include at least an input capacitor whose voltage rating may be lower.

- Heat dissipation - perhaps the most important factor to consider - it is a linear regulator, which means that the voltage drop will result in heat that must be safely dissipated. The common package is small SOT-223 which relies on the PCB it is soldered to act as a radiator.

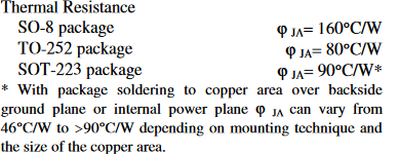

From the same data sheet - this suggests a value of Theta = 90 degC/W, albeit it could be lower if the PCB was 'generous'... but this is unlikely to apply to the modules you are probably looking at.

To figure out if this is a problem, you need to know the current your circuit will take, as the chip dissipation will be:

Dissipation in Watts [P = (Input Voltage [Vin] - Output Voltage [Vout]) * Current in A (I)

As an example, let's make up some values:

New Battery voltage Vin = 9.6 V

Output Voltage Vout = 3.3 V

Current demand I = 0.25 A

Dissipation [P]= (9.6 - 3.3) * 0.25 = 1.575 W

Then, the internal temperature rise of the AMS1117 = Power Dissipation [P] * Theta

= 1.575 * 90 = 142 degC above ambient temperature

If we assume your room temperature is 20 degC, this implies the AMS1117 temperature would be

(20 + 142) = 162 degC

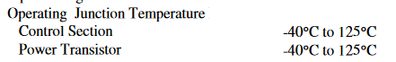

Unfortunately, the same data sheet also says:

So, the temperature just estimated would be nearly 40 degC above the 'absolute maximum' allowed value.

If you tried to use the device under these conditions it would probably go into 'thermal shutdown' in an attempt to protect itself. Experience with other 'maltreated' voltage regulators I have seen suggests it would prematurely completely fail, if regularly driven to these limits. Whilst chips often have maximum junction temperature specified as 125 deg C and higher, it is also well established, the hotter it runs, the quicker it fails!

--------------

Of course, this calculation was only based on some assumed numbers ... if the current drawn was much less, say under 100 mA, then it would probably be fine.

Similarly, if the input voltage is dropped, then the dissipation is obviously reduced. For example, the device is sometimes used to power a 3.3V chip, like the ESP32, when the incoming power from USB is only 5V.

I hope this is a useful explanation, and that you can follow the simple maths, so that you can repeat them with your own numbers.

Good luck! Dave

Hi @davee

Thank you for all your time and info in your response. Looks like it shouldn't be a problem.

Hi @darkar,

As you say, it might not be a problem.

Personally, I don't know the details of your project, but generally I would choose to use 4 X 1.5V batteries ... AA or (better still) AAA ... in a plastic holder, rather than a 9V battery to power a 3.3V device ... unless space is at a premium. They are cheaper than the small 9V battery, and will last longer before replacement, as well as giving the AM1117 a cooler time.

Good luck. Dave

Hi @davee

I am working on the ESP32CAM robot car project but was going to 3D print the body for the car which would hold 5 AA's I am going to try and do this with a group of kids so would like it as simple as possible. So I think I am going to try the 5 V mini version with the three terminals.

Thanks for your help.